Monocrystalline Solar Panels

By Finn Peacock, Chartered Electrical Engineer, Fact Checked By Ronald Brakels

Monocrystalline solar panels are made from monocrystalline (aka mono) solar cells and look like this:

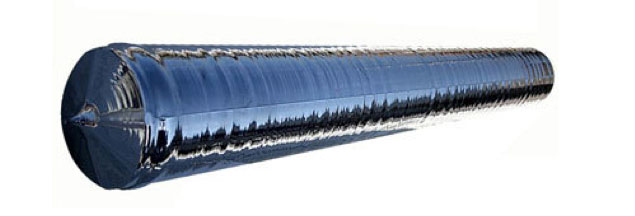

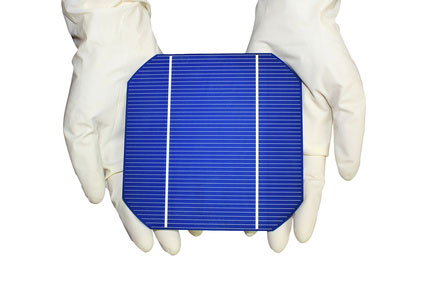

The most obvious characteristic of a monocrystalline solar cell is that it has its corners chopped off! This is done because these solar cells start out as a cylindrical monocrystalline ingot that looks like this:

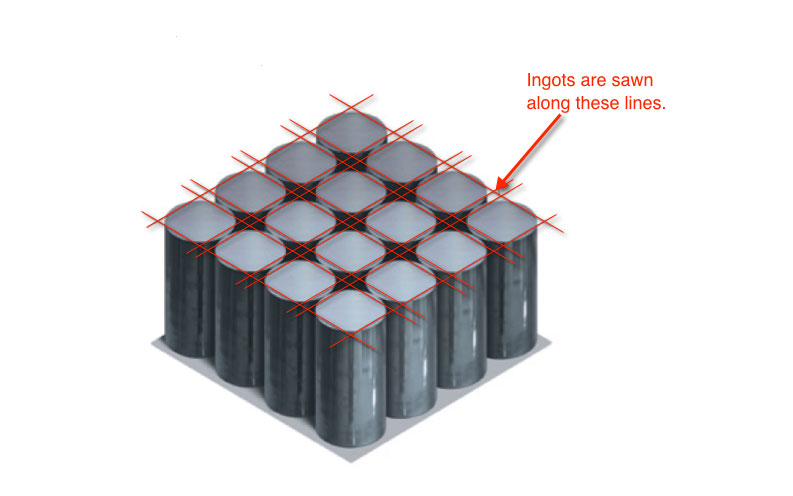

These ingots are “squared” off with wire saws as shown below. If they were to make them completely square they would waste heaps of silicon. Hence the rounded corners.

The resulting squared ingot is then sliced like salami to make the wafers. The wafers are still not capable of generating any electricity though! First they need some serious processing.

The stages to make a monocrystalline wafer into a monocrystalline solar cell that will generate electricity from light are these:

Texturing: The wafers are etched with all sorts of nasty chemicals to remove a tiny layer of silicon, leaving an irregular pattern of pyramids. This creates a bigger surface area to absorb more light.

Diffusing: The surface of the wafer has phosphorus diffused into it, giving it a negative electrical orientation in contrast to the bottom of the wafer that is positively oriented.

Coating: The cell is coated with silicon nitride, which reduces reflection; ensuring as much light as possible is absorbed.

Printing: Metal conductors are printed onto the wafer to collect the electricity that is produced.

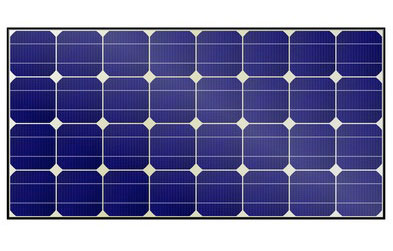

Laying Up The Monocrystalline Solar Panel

The finished solar cells are soldered together to form ribbons – usually about 10 cells long. 6 ribbons are then usually laid out to make the matrix of 60 cells that form the solar panel.

The matrix of cells is laminated onto special anti reflective, tempered glass with a large plastic backsheet. The glass assembly is then placed into a frame, a junction box is fitted for electrical connections and you have your monocrystalline photovoltaic solar panel!

The finished panel will have an efficiency of between 15 and 20%, and, if it is well made, should easily last 30 years. If you want to see a current selection of monocrystalline solar panels on the Australian market, then you can use my solar panel comparison chart.

As for the difference between this technology and polycrystalline – and which is better – see my article on mono vs. poly solar panels. You may find the answer surprising! You can also learn more about polycrystalline panels here.