Solar Panels – Choose Your Technology!

By Finn Peacock, Chartered Electrical Engineer, Fact Checked By Ronald Brakels

If you’re looking for a solar power system, the parts that collect all the sunshine and most of the attention are the solar panels.

These days, if you get quotes for rooftop solar, you’ll almost certainly be offered monosilicon half-cut PERC panels.

If you’re new to solar, the last part of the previous sentence looks like gibberish, but here’s an explanation of what those weird words mean:

- Monosilicon: The solar cells were cut from a single large crystal of silicon. Also called monocrystalline.

- Half-cut: Rather than using square solar cells as in the past, they are instead cut in half to make rectangular cells.

- PERC: A commonly used method of improving output.

While most panels going on roofs have these three features, two other types of panels are still used in small numbers:

- Full cell panels

- Shingle panels

Two panel types no longer going on roofs are:

- Polysilicon panels

- Thin film panels

And some panel technologies you may hear about are:

- Lightweight panels

- Flexible panels

- Dual glass panels

Technology isn’t what’s important

There are three criteria solar panels need to meet and none of them involve specific technologies. The three things your solar panels need to be are…

- Reliable

- Suitable for your needs

- Within your budget

If these three areas are covered, you’ll have good panels. But so you can understand technical terms you may come across when looking to buy solar, I’ll briefly outline the main panel technologies below.

Monosilicon

Because monosilicon solar cells – cut from a single large crystal – are more efficient than polysilcon with multiple crystals, it’s now the only type that goes on roofs.

Single crystal silicon ingots are grown in temperature controlled electric furnaces called pots. Their interiors are cut from pure quartz – one of the few substances that can handle the temperatures required without causing contamination.

When they come out, they look like this:

Monosilicon’s higher efficiency allows more generation from a limited amount of roof space. It also lets fewer panels do the same work, which reduces labour costs.

Polysilicon is cheaper to make and still often used in solar farms where energy efficiency is less important.

Half-cut

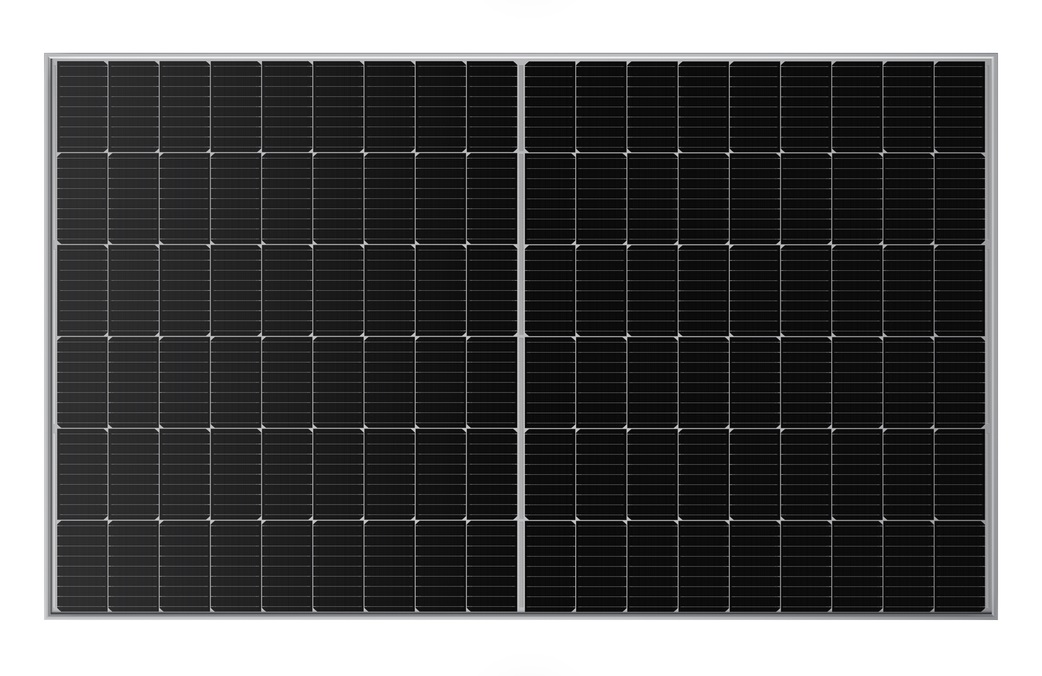

After a silicon ingot is made it’s cut into thin squares. In the past, these were used to make full cell panels with square solar cells. But these days, they are almost always cut into 2 rectangles to make half-cut cells. Using half-sized solar cells gives three advantages:

- It increases output by around 3%.

- It can slightly reduce losses from shade.

- Their smaller size means they’re less likely to suffer damage from microcracks if the panel is flexed by wind or other causes.

REC was the first company to introduce half-cut panels in 2014 with their TwinPeak series. It took the rest of the industry years to catch up because it was difficult to perfect the automated machinery required to quickly and reliably solder the over 100 half-cells in a typical solar panel.

This Longi half-cut panel has 108 half-cut solar cells. Most have more. (Image Credit: Longi)

Full Cell Panels

There are still some manufacturers selling full cell panels, such as SunPower Maxeon, but they’re far outnumbered by half-cut panels.

Shingle Panels

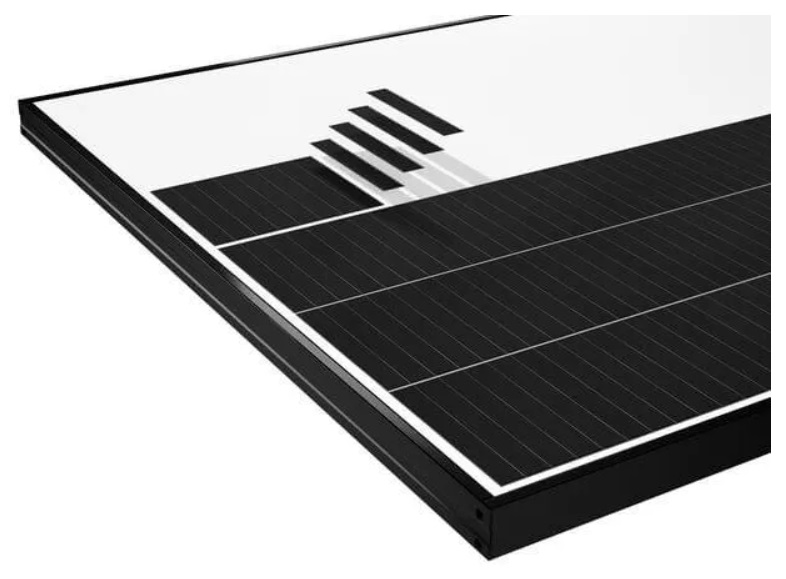

One of the few panels still being used today that don’t have half-cut cells are shingle panels. Rather than cutting silicon squares in half, they are instead cut into 4 or 5 strips and placed on solar panels so they slightly overlap each other – like shingle tiles on a roof.

This diagram of a SunPower Performance shingle panel shows how the silicon strips are arranged. (Image credit: SunPower)

The overlapping eliminates wasted space between cells where light isn’t converted into electricity. It requires more silicon per watt of capacity than other panels, but this isn’t a major drawback as solar silicon is far cheaper than it used to be.

PERC Panels

PERC stands for Passivated Emitter and Rear Cell. It’s a coating on the back of solar cells that works better than the aluminium it replaced. You can read more here, but all you really need to know is it’s a method of improving efficiency now used by most panels.

The technology first became available in 2012 but sales didn’t perk up until a few years later. Some early PERC panels suffered faster than expected capacity loss but manufacturers now know how to limit this and it’s no longer a problem for panels from reputable companies.

Thin Film

Ten years ago, some panels going on Australian roofs were thin film ones made by First Solar. While there are several thin film technologies, these ones used cadmium telluride solar cells. As silicon beat them on efficiency they’re no longer used residentially but are still installed by some solar farms. Currently, they’re around 2% of world solar panel production.

While their name may make them sound light, thin film panels weigh around the same as silicon ones, per square meter. This makes them different from…

Lightweight Solar Panels

Some roofs can’t handle normal solar panels but can take lightweight ones. These weigh around one-third as much as normal panels. They are used for some commercial installations but only rarely for homes.

Lightweight panels usually have silicon solar cells but use tough plastic to protect them instead of glass. They cost more than comparable conventional panels, but can still be far better than not having panels at all.

Flexible Solar Panels

Lightweight panels are also usually flexible – to a limited extent. If you have a curved or unusually shaped roof, they often can be bent to match.

Dual Glass Panels

Most solar panels going on roofs have a tough plastic backsheet with a glass sheet over the solar cells. But an increasing number have glass on the front and back. This is done because the glass used is strong, long-lasting, and doesn’t cost much more than durable plastic. But provided a panel is good quality, whether it has one sheet of glass or two makes little practical difference for home owners.

Future Tech

Solar panels will continue to improve in efficiency and fall in price. Despite occasional reports of breakthroughs, change is likely to be gradual. At the moment nothing is set to replace silicon, but in the future it may be paired with materials such as perovskite. While major changes will eventually occur, silicon only solar panels will be the main type going on roofs for years to come.

Solar Jargon

I’ve covered the main types of solar panel technologies, but haven’t come close to covering all the jargon you may hear when you look into buying solar. But – unless you’re honestly interested in the technical details – my advice is to not worry about it.

What matters is that the panels going on your roof are reliable, suitable for your needs, and within your budget.

Finding Quality Panels

The goal of SolarQuotes is to take the stress out of getting reliable, well-installed, solar. To help you out, we’ve put all the manufacturers of solar panels and other solar hardware we consider reliable and well-supported in Australia on this page.

We’ll also back up any system you get through an installer we refer to you with our Good Installer Guarantee. So if you’re interested in a modest solar system or – better yet – want to fill your roof, we can arrange quotes.