Millions of solar panels sending Australian solar energy to Singapore via a 3,800 km cable. Crazy or genius?

I first learned about how the electricity grid works in the early 1980s, which meant I was taught the conventional wisdom of the times: high-voltage AC (alternating current) transmission was ubiquitous because it was the most efficient way to send electricity the long distances needed by the electricity grid.

So I was intrigued to hear that projects such as Sun Cable, the proposal to export solar power generated in the Northern Territory to Singapore, will be designed around high-voltage DC (direct current) technologies.

To find out why, I chatted to Sun Cable’s Andrew Coffey about the project.

“AC is quite hard to transmit over very long distances,” he explained.

That’s because of the reactive way AC interacts with the cables that transmit it:

“An overhead cable acts as an inductor, so you have to put a bunch of capacitors along the route to counteract that,” he said.

The opposite is true of an underground cable, Coffey said: the cable acts as a capacitor, so designers have to respond by installing inductors along the cable route.

“There’s a tipping point where the cost of converting the signal from AC to DC outweighs the cost of all the capacitors or inductors you have to install”, he said.

Direct current isn’t affected by capacitance or inductance, so while there are some losses from the resistance of the cable, in a high-voltage application losses are less than in AC transmission systems.

“When you’re doing long distance, very high power, HVDC is more cost efficient than AC transmission,” Coffey said.

For a more detailed comparison of AC and DC transmission systems, Section 2.2 of this document (PDF) by America’s Energy Information Administration is handy. Its assessment is HVDC’s economic advantages come from the reactive losses Coffey mentioned, but also lower loss from skin effect (the non-uniform distribution of current in the conductor’s cross-section) and lower right-of-way requirements because HVDC has a smaller footprint (you only need two conductors, compared to six conductors for a high-voltage AC system).

Importantly, the EIA paper notes, HVDC is asynchronous – it doesn’t depend on multiple networks being synchronised (operating at the same voltage, system frequency, and system timing) – meaning HVDC is also an ideal technology to interconnect different AC systems.

And in submarine applications, the EIA paper notes HVDC can often be the only option: at some point, the capacitance of an AC system limits its maximum transmission distance.

Coffey said the systems under evaluation by Sun Cable are 525 kV, but they’re also modelling a 600 kV design in case that technology becomes available in time for the planned construction.

Engineering Sun Cable

The company isn’t daunted by the engineering involved, he said, because:

“What we’re doing has been done before over shorter distances. We’re not doing anything new in that sense, we’re just using a lot more cable.”

“There just hasn’t been a situation where you have both a very low cost electricity generation source, which we have in northern Australia; and you have a customer who has a desire for more renewable energy electricity in their system and limited opportunities to do that in-country.”

The particular dynamic of generating power in northern Australia for consumption in Singapore, “hasn’t really occurred in history”, Coffey said, because the traditional model is to transport the fuel (gas or coal) and burn it in a generator at the destination.

“There are no technical barriers,” he said, “there’s just the commercial question about whether it makes sense to deploy such a long cable”.

Coffey told SolarQuotes the biggest technology development enabling Sun Cable is the steady increase in the maximum voltages HVDC systems can carry, because higher voltages reduce losses.

“Technology development here is largely materials science,” he said. “New polymers and enhancing those polymers to ensure they provide the necessary insulation to carry the very high voltages.”

“Higher voltages reduce the metal content in the cable, and that reduces the weight, meaning you can lay cables in much deeper water.”

Currently the deepest submarine HVDC cable in the world connects Sardenia to Italy, with sections as deep as 1,600 metres – nowhere near the depth that optical fibre telecommunications cables operate at, but deep enough that Sun Cable can navigate a route to Singapore.

However, the huge weight of the HVDC cable gives it a relative advantage over a fibre optic cable: it’s far too heavy to suffer the storm damage that regularly shuts down communications links. That leaves shipping as the main external risk to a cable’s operation.

Europe is the hotspot for HVDC submarine cable manufacture, Coffey said, with vendors including ABB, Prysmian, Nexans, and NKT. Japan’s Sumitomo also manufactures HVDC systems, and while China is home to more than one manufacturer, its systems are mostly produced for local projects.

Sun Cable is still working out the commercial details of the project, as well as optimising the size of the solar energy plant and battery to ensure it works with the expected customer loads, and finally, doing the necessary environmental work.

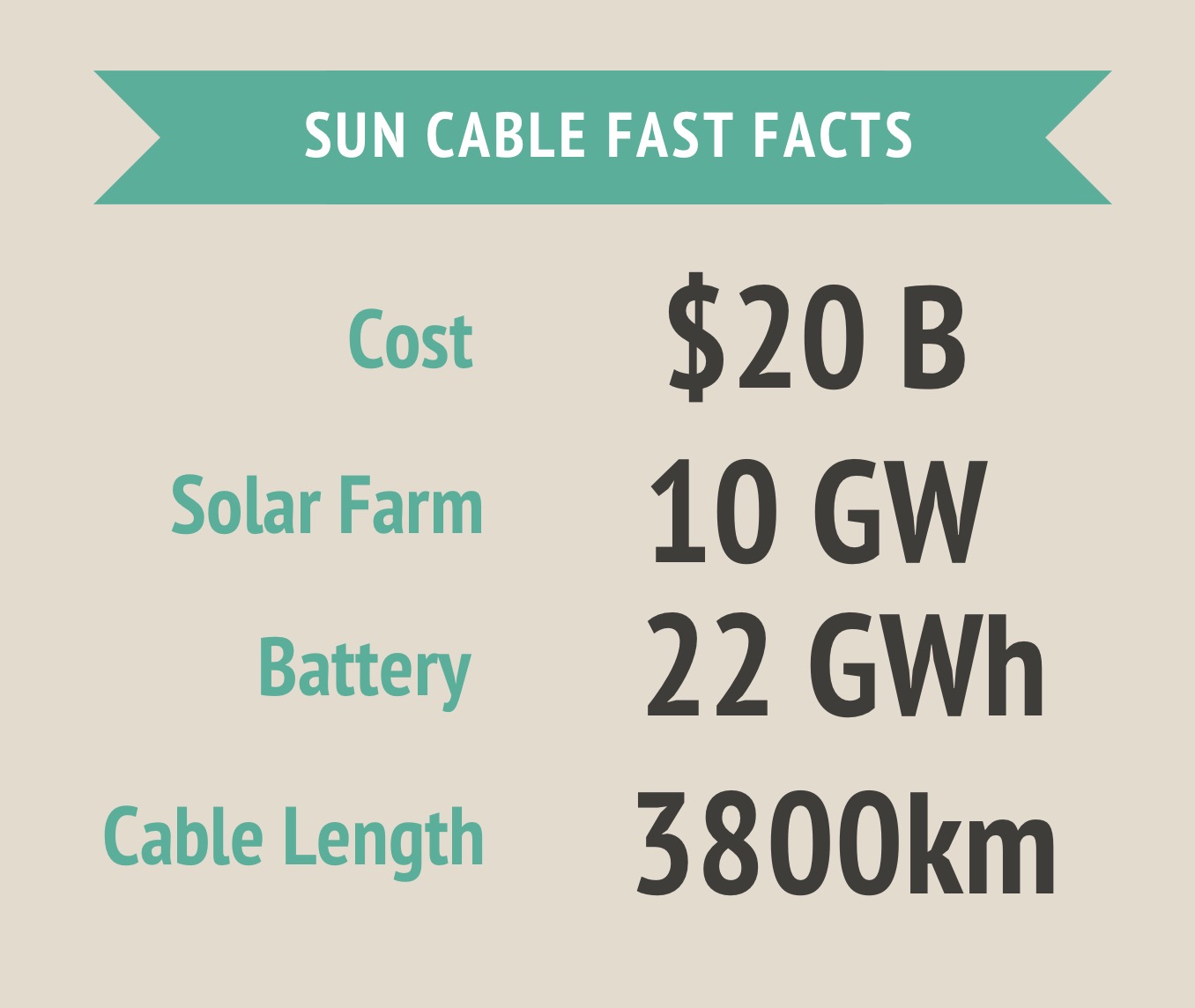

“It all looks set to be very good,” Coffey told us. “The exciting thing is that the site and the solar farm being very large at 10GW, is such a tiny proportion of the available energy resource in Central Australia. So there’s no barrier to increasing the renewable energy in the whole South-East Asia system in the next decades.”

RSS - Posts

RSS - Posts

Interestingly, we toured a hydro station in central south-island NZ about 30 years ago – the plant had a separate HVDC inverter enclosure, and they were shipping DC power to the north island as I vaguely recall – but I also only recall a single conductor (earth return) – unless my recall is flawed!

I understood the line went submarine between island shores.

Also vividly recall the overhead line was crackling significantly – because the air was slightly misty – my thought was that there would therefore be significant transmission losses.

I guess it becomes a balancing act…

Just so long as the design includes a return cable. Earth return design carries enormous risk. Basslink was planned for earth return, but this design was not permitted, in part, because of stray current corrosion risk to buried structures, including oil & gas infrastructure

A pity this surplus power cannot be sent down south to provide a bit of competition to the resident bunch of overcharging pariahs.

If this is viable over 3800km of cable it pretty much could reach any part of Australia. I would also guess that it would be cheaper to lay over land than under the ocean.

Perhaps a worthwhile invest project for our superannuation funds who currently have surplus billions to invest.

So why not supply Australia first? Or is it a case of export it to keep the prices high here (like so many other “exports”).

Come on LNP! Here’s an infrastructure project that can employ all those millions of out-of-work miners.

What’s the bet the price to Singapore will be way less than we currently pay for power (like gas).

Hi Jeff,

My understanding of this project is that it would supply NT first, with the rest (honestly, it’s the vast majority) then exported to Singapore.

@Jeff. its a simple case of Singapore is willing to pay more thus the project can make money. For the eastern states you’d just build the panels in….the eastern states.

Richard Chirgwin,

You state:

“…HVDC has a smaller footprint (you only need two conductors, compared to six conductors for a high-voltage AC system).”

Why six conductors for HVAC? Isn’t it a minimum of three – phases A, B & C that are sinusoidally 120°-phased apart? Or is there some other arrangement?

You also state:

“Coffey said the systems under evaluation by Sun Cable are 525 kV, but they’re also modelling a 600 kV design…”

I presume that’s the technological limit now for undersea HVDC transmission?

In 2017, Professor Andrew Blakers referred to the limits of HVDC transmission technology in the world as now operational at 1,100 kV over 3,000 km at 12 GW power capacity in China – that’s aerial with about a 10% loss rate.

Basslink (Tasmania – Victoria) is apparently 400 kV over 290 km at 0.5 GW power capacity.

See Blakers presentation from time interval 08:46 through to 10:56: [2017 CURF Annual Forum – Andrew Blakers keynote] https://www.youtube.com/watch?v=y1IC6TiNDRc

Also: https://www.sciencedirect.com/science/article/abs/pii/S0301421513001845

Since this cable may have some durability advantages of existing fiber in case of storms I wonder if they could include fiber in the design. Also, fibre optic cables make great cheap seismic monitors that could be another service they could work with someone to provide given tsunami risks in the area.

Undersea HVDC is as the article says, not new. I recall reading in New Scientist in 1971 of such a link between Denmark and Sweden. That mention was scant on details, focusing on the freedom from having to synchronise the two national grids, rather than any efficiency and economy gains. (Or I’ve forgotten those extra bits.)

Those converters used SCRs (Silicon Controlled Rectifiers), now ancient technology, arranged in tall towers reminiscent of a HV test lab, to deal with the high transmission voltage. It was considered pretty nifty back then.

As for expandability, I’ve read somewhere that covering just 7% of Australia’s deserts with solar panels could provide the world’s grid energy needs. That was a few years ago. I don’t know how well that was researched, or how consumption has increased since. And doubtless beyond some distance, it’d be more economical to export the energy as ammonia (hydrogen transport medium) – not least because that also provides storage.

When I first read about this project I looked over another potential project. The U.S. state of Hawaii to Baja California (Mexico) is about the same distance. Maybe Hawaii could import their power as well. Their electricity cost is currently very high and space for renewables is limited.

I would be greatly interested in what part of the 16 Billion $ are the cable costs, also the approximated energy losses of transport.

I have seen that calculated here: https://link.springer.com/article/10.1007/s41825-020-00032-z