Ninety-eight percent of the world’s solar cells are made from silicon. This is thanks to its suitability as a PV material and its low cost compared to alternatives. While the price of solar silicon has its ups and downs, the overall trend has been downwards. It reached a record low in June 2020. After taking inflation into account, it was around one-thirteenth of its 2007 price.

But the record low didn’t last, and over the past 12 months it has gone from under $7 US per kilogram to over $28 US. In relative terms, this has been the largest solar silicon price increase in history.

Prices were low last year because massive new solar silicon production capacity had been built but demand was weak due to the pandemic-related worldwide economic slowdown. As demand has increased, so have solar silicon prices. This was mentioned by Michael in his recent article on Jinko Solar.

A wide range of commodities including timber, iron ore, and copper has surged in price recently. This is a side-effect of the world’s current economic state and I don’t think it’s anything we should be too worried about. While supply and demand don’t always work in our favour, they are reliable and I expect them to sort things out given time. Worldwide pandemics are not normal, so we shouldn’t expect world markets to be normal either.

But because some people have gotten their knickers in a twist over the solar silicon price hike, I’ve decided to do two things:

- Work out the amount of silicon in a typical rooftop solar panel.

- Use this to determine how much the hike in solar silicon price will add to the production cost of a solar panel.

Ups & Downs

There are two basic types of silicon solar cells:

- Monocrystalline: These cells are cut from a silicon ingot that’s one large crystal. It cost more but gives higher efficiency.

- Multicrystalline: These cells are cut from an ingot containing multiple crystals of silicon. It’s cheaper than monocrystalline, but the cells have lower efficiency.

Most solar panels going on Australian roofs now have monocrystalline solar cells, but the raw material for monocrystalline and multicrystalline cells is the same — high-quality polysilicon of at least 99.9999% purity. The graph below shows polysilicon prices since 1977. It’s in US dollars adjusted for inflation, so the prices are all in today’s money. It shows ups and downs, but the general trend has been down:

The uptick at the end of the graph doesn’t look too bad, but it’s the largest relative increase in price over a year that has ever occurred. Prices almost doubled from June 2020 to the start of the year and have more than doubled since then:

Because it’s the largest relative price hike ever, it’s easy to understand why it has caused some consternation. While an increase was expected, some are concerned the price will keep rising. One thing with the potential to kick prices higher is accidents at solar silicon production facilities in China — the country where almost all the solar silicon on our roofs comes from. They have a bad habit of suffering explosions.

I assume these industrial accidents are the result of so much new capacity being built so quickly in a country with less focus on safety than our own. I don’t think it’s a natural feature of Chinese silicon plants, so hopefully there won’t be many more explosions before they get a handle on it.

Fingers crossed.

How Much Silicon In A Panel?

To be nitpicky, there’s a lot more silicon in the glass of a solar panel than in its solar cells, with glass being roughly 20% silicon by weight. There’s also silicon-based sealant between the panel and its frame. But this is not high-quality 99.9999% pure solar silicon. I’m only considering the high-cost stuff solar cells are made from.

To work out how much solar silicon is in a panel I’ll need to know:

- The thickness of modern solar cells.

- How much area the cells in a typical solar panel cover.

- How much silicon is wasted in manufacture.

Thickness: The width of solar cells varies, but many are now only 160 micrometres thick. That’s 0.16 mm and little more than twice the average thickness of a human hair.

Area: Not long ago the standard size of a rooftop solar panel was 1.65m by 1m. But as they have crept up in size over the past year or two, I’ll now consider a panel 1.76 meters by 1.04 meters as typical for rooftop solar power systems. After allowing for the space taken up by frame edges and the little gaps between cells, I’ll assume the total solar cell surface area is 1.7 square metres.

Wastage: I don’t have any precise figures for silicon wastage in solar panel manufacturing. But after accounting for…

- Kerf from diamond wire saws cutting silicon ingots into wafers.

- Squaring off rounded edges on monocrystalline ingots.

- Accidental breakage and defects.

…roughly as much silicon is lost in manufacture as ends up as solar cells on panels. A lot of what is wasted can be recycled, but this does little to offset costs.

Crunching Silicon Numbers With Silicon

By entering figures for area and thickness into my calculator’s silicon chip, I can determine the solar cells in a typical panel have a total volume of around 272 cubic centimetres. Because silicon has a density of 2.33 grams per cubic centimetre, this comes to 634 grams of silicon.

If I double it to account for wastage, then roughly 1.3 kg of silicon is required to make one solar panel.

The PVinsights page tells me high-quality solar silicon in China currently costs $29.40 US per kg, while average-grade is less than $2 cheaper at $27.63 US.

Using the high-quality figure with today’s exchange rate of 0.76 US greenbucks to the Australian dollarydoo, it requires around $50 Australian worth of solar silicon to make one solar panel.

Compared to the average solar silicon price of around $9 US per kilogram in 2020, this represents an increase of around $34 Australian dollars per panel. With GST it will come to around $37.

For a 370 watt panel, which is a common size these days, the price increase comes to 9 cents per watt. After adding GST it will come to around 10 cents per watt.

Effect Of The Price Spike

After including GST but without any other adjustments, the $37 Australian dollar increase in the cost of silicon per panel will increase a solar system’s cost by the following amounts:

Obviously, this is not good. Low-cost solar is humanity’s last, best, hope for preserving the natural environment and giving our children the same chance of being eaten by a wild animal that we had; so any price increase is not appreciated.

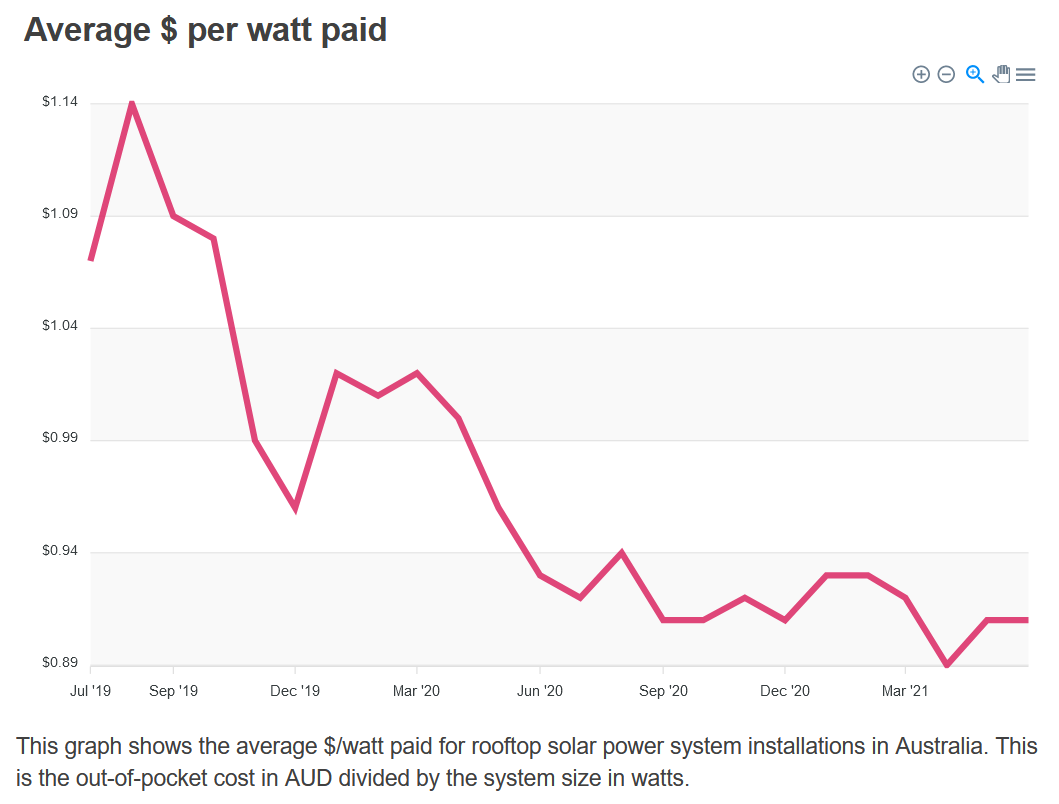

The good news is this kind of price increase is not going to be enough to stop solar making sense in Australia. The graph below is from the SolarQuotes Australian Solar Price Index. It shows the average cost per watt for rooftop solar systems installed in Australia.

Note this gives the average cost of all solar installed in Australia as reported by reviewers on SolarQuotes. This includes some crap solar installed by cowboys or possibly their horses. Rather than aiming for the cost per watt on this graph, you will be much better off paying a little extra to get a system from an installer who does high-quality work:

The graph goes up to June 1st and, as you can see, the cost of rooftop solar then was close to being its lowest ever. A 10 cent per watt increase would only raise the cost of a system to around what it was in March last year.

Rooftop solar made plenty of sense then and it will continue to make sense even if solar silicon prices manage to double again and push the price all the way up to what it was in the middle of 2019. A price increase that large would be unfortunate, but not a disaster.

It remains to be seen if Australian households will suffer a 10 cent per watt increase in the cost of new solar power systems. While I don’t expect solar silicon prices to return to last year’s prices any time soon, I do think it’s likely they’ll fall from their current peak.

Also, because suppliers and installers were expecting the increase, and because manufacturers are constantly working to lower costs in other areas, Australian households are likely to be at least partially cushioned from the recent price hike. Rather than an increase in solar system prices, we may instead see a temporary pause in solar system price decreases.

There’s no guarantee solar silicon prices won’t rise further, but if they do it will be a self-correcting situation. Higher prices will encourage more solar silicon production while decreasing the demand for solar panels and eventually a new equilibrium will be reached. After this occurs, solar silicon is likely to revert back to declining in price.

Left alone, markets will sort it out. There is only likely to be a prolonged problem if our leaders start deliberately throwing spanners in the works, but they’d have to be complete morons to do that.

You know, now that I think about it, we may be at greater risk than I thought.

RSS - Posts

RSS - Posts

what brand/model do you think would work well in Thredbo 2625 for solar/heatpump hot water ( instead of existing reticulated LPG and external wall-mounted instantaneous gas HWS) ?

From what I’ve heard, Sanden is a reliable choice for hot water heat pumps, with a six year warranty on the heat pump. But they do come at a premium price. For peace of mind, I suggest going with a system with a good warranty on all components such as Sanden. Some manufacturers only offer 12 months warranty on some components, so you run a real risk going with them. While you are protected by Australian Consumer Guarantees, it is better to just get a reliable system in the first place.

Another significant impact on module prices has been the massive increase in sea freight costs over 2020 levels. Container rates ex China have more than doubled in 2021 and for an average FCL of 800 resi modules, this would add another $2.50-$3 ex GST to the landed cost of a module

Good point. On the bright side, at least there’s no canals between here and Shanghai for ships to get stuck in.

Very nice article again, I really like the way you cut down things, thank you.

Please have a look at the ITRPV https://itrpv.vdma.org/en/ they give estimates and predictions with lots of numbers for PV. In their 2021 edition they have poly-Si consumption of 2.10 to 2.15 g/W leading to around 800g for a 370 Wp module. So price increase due to silicon is around 500 to 600$ for a 10kW system. For Europe prices for logistics have increased by a factor of more than four. At the end prices have increased and until everything settles might increase more.