Image: 1StopWarehouse

As a Licensed Electrical Inspector, I’ve seen heaps of solar power system setups. This month, let’s chat about something you might not consider important: solar labelling. It might sound boring, but trust me, how well it’s done often tells you a lot about the quality of the whole install.

When picking the right system, most people zero in on solar panels and inverters. But let’s be real—there’s a bunch of those that meet the standards and do the job pretty much the same way. So, how do you pick from quotes that seem like twins? Look at the quoters’ installation quality. A top-notch installer often shows their colours in the small stuff, like getting the labelling spot-on.

In this post, I’ll dive into why labelling is so important in grid-connect solar setups and why neglecting it could spell trouble. Whether you’re a homeowner eyeing a solar power system or a solar installer, understanding the labelling game is key for a safe and smooth solar journey.

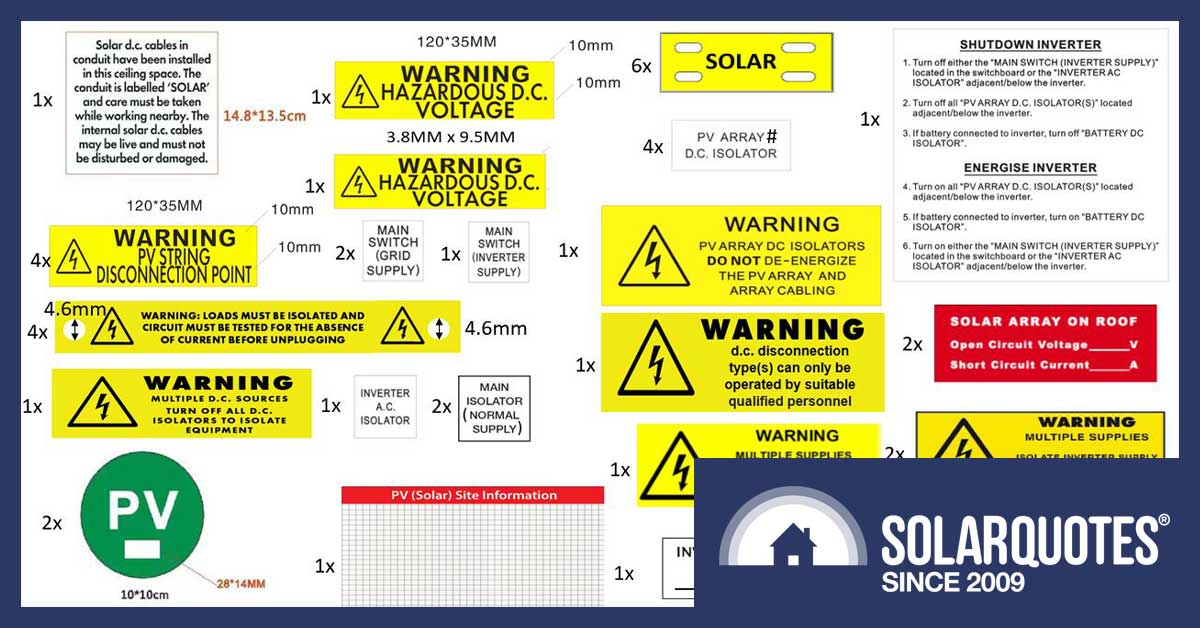

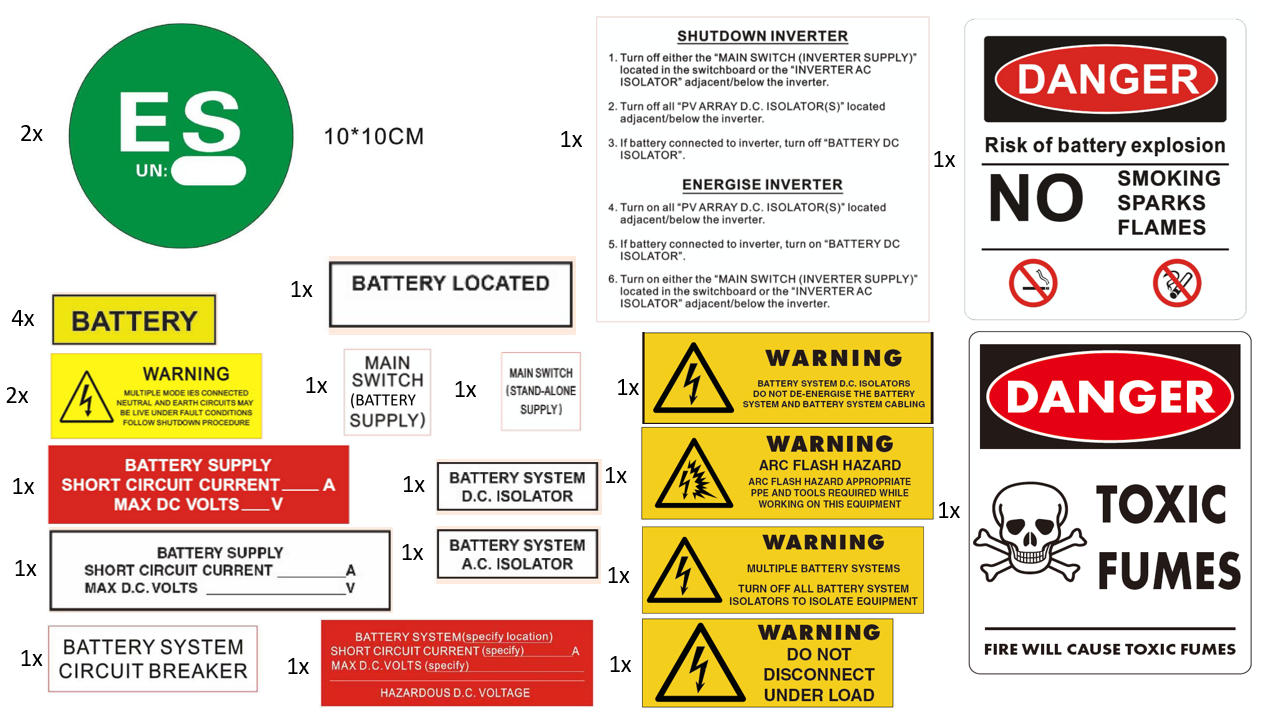

Adding batteries? Then you’ll need even more labels… Image: 1StopWarehouse

The Solar Labelling Challenge

For the past decade, installers across Australia have grappled with the overwhelming number of safety labels required for residential solar and battery systems. Many see it as a case of regulation going overboard.

Even those setting industry standards have admitted we had to simplify this labelling business. I have heard some standard-setters say they want simpler labelling and admit to failing at this. But you know what? Doing it right isn’t as much of a chore as it may seem. It’s time to break free from “label stigma” and use it as an advantage.

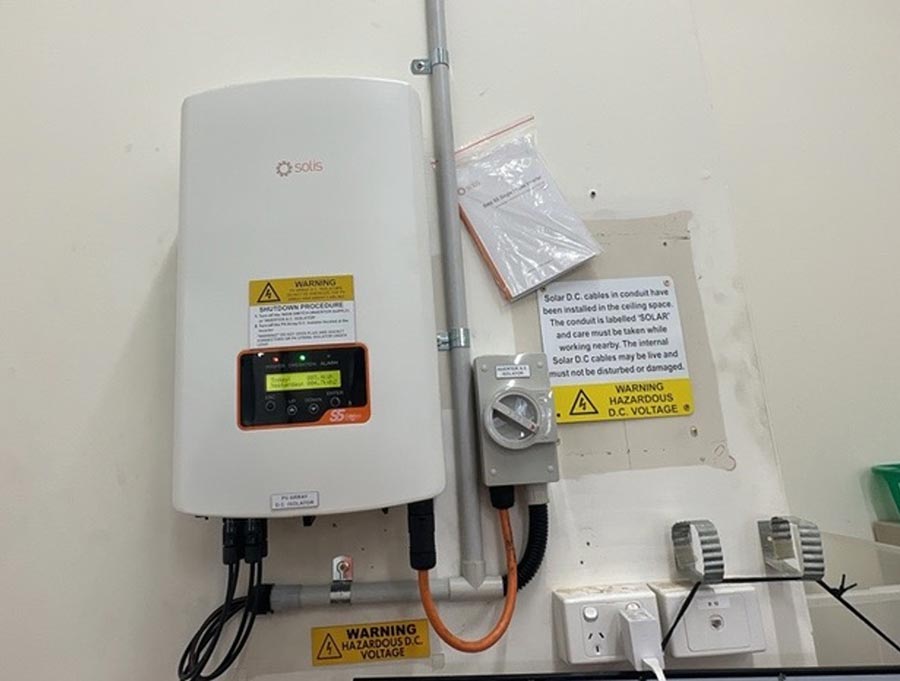

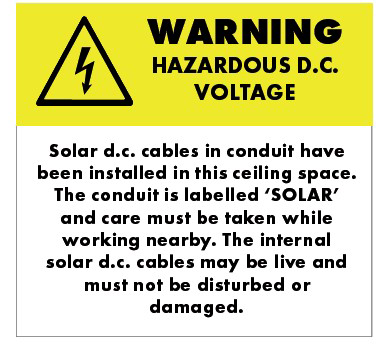

This electrical safety label belongs in the access to the roof cavity, not adjacent to the inverter.

1. Know Your Standards

Start by getting cozy with the relevant standards, like AS/NZS5033. Yeah, it might seem tedious, but these standards are the rulebook for safety and quality in the solar power game. Knowing them lets you size up whether your solar installation checks all the labelling boxes. Set aside some bedtime reading, or plenty of other online resources are available if you are like me and want things that are easier to read and understand.

2. Don’t Skimp on Label Quality

Don’t be tempted to go cheap. Trying to save $20 on a budget kit will backfire in the long run. Those low-quality labels won’t stand up to Australian weather, fading and cracking over time. It will cost more to return to the site and replace them in the future, and try to repair the damage to your reputation for installing an inferior product. It’s a smart move to stick to high-quality labels for reliability that lasts.

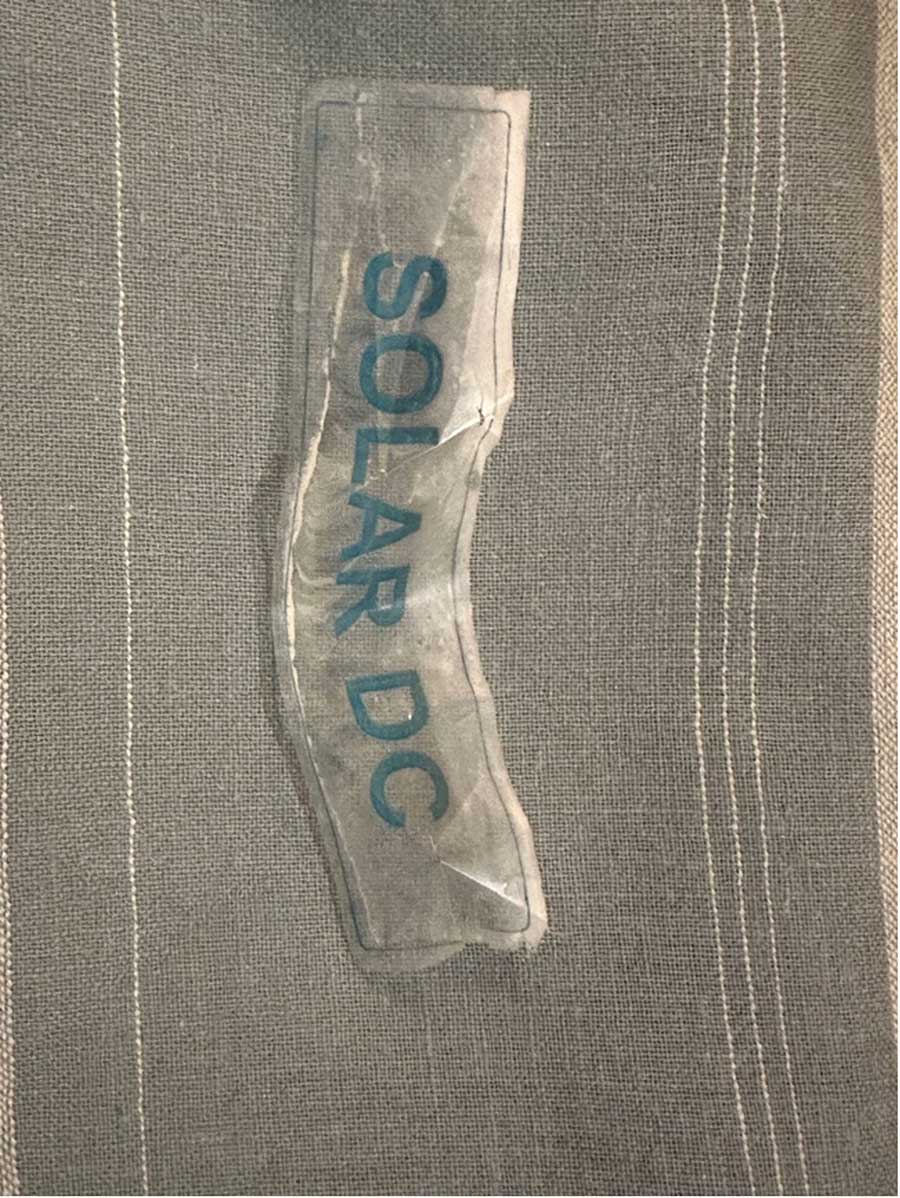

This label was once affixed to a DC conduit exposed to direct UV from an installation only three months ago.

Our Australian solar installations face some tough conditions – scorching sun, gusty winds, and heavy rain. So, it’s crucial to choose labels that can handle the heat. Those that fade or fall apart just won’t cut it. I have seen countless systems with safety labels that have faded so much that you now can’t tell what colour it once was or is supposed to be. Invest in labels that can endure the elements, ensuring your critical information stays clear for years to come.

3. Stick ‘Em Right

How you stick them matters, too. Follow the manufacturer’s instructions. If a label needs a hole for a cable tie, make sure that hole isn’t too close to the label’s edge, or it might not hold up. Use a good quality adhesive designed to cop the conditions the environment will throw at it.

Consider the surface you are sticking it to. Remember that labelling your conduits (which are round and PVC) may require a different adhesive material or technique to be effective. Properly stuck labels keep everything clear, reducing the risk of mix-ups and accidents.

This label identified the conductors at a disconnection point on the roof, became brittle in a short time and snapped away from its fixing to the cable.

4. Less is More

Using all the labels just to use up the whole kit can clutter your solar installation and confuse everyone down the line. Only use them where they’re needed to identify the equipment accurately. You never want your system labels to resemble a confusing jigsaw puzzle. A well-organised setup not only makes things safer, but also looks better. Some of the best solar companies even offer custom-made labels with contact details and specific branding (looks great on the shutdown procedure label), adding a personal touch to your solar power system.

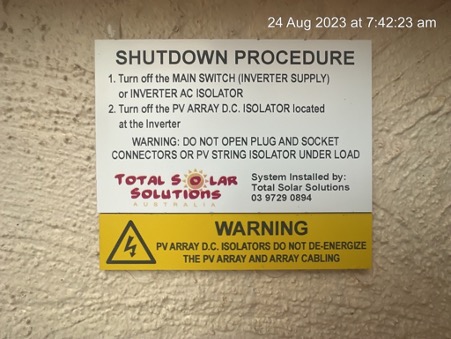

This compliant shutdown procedure label is installed adjacent to the inverter, with branding included.

5. No More Chicken Scratch

Who remembers back in the day when we used to jot down solar quotes by hand? Seems pretty dodgy now. Well, we’ve come a long way in the industry. Handwritten labels don’t exactly scream ‘professional’ either.

There’s not much worse as a Licensed Electrical Inspector than going to the PV Site Information label at the main switchboard / meter and seeing something that looks like my 7-year-old whipped up at after-school care. Keep it pro with pre-made, clear labels with all the right info. It’s a small detail but goes a long way in showing you care.

This PV Site Information label is at the meter box and has been handwritten.

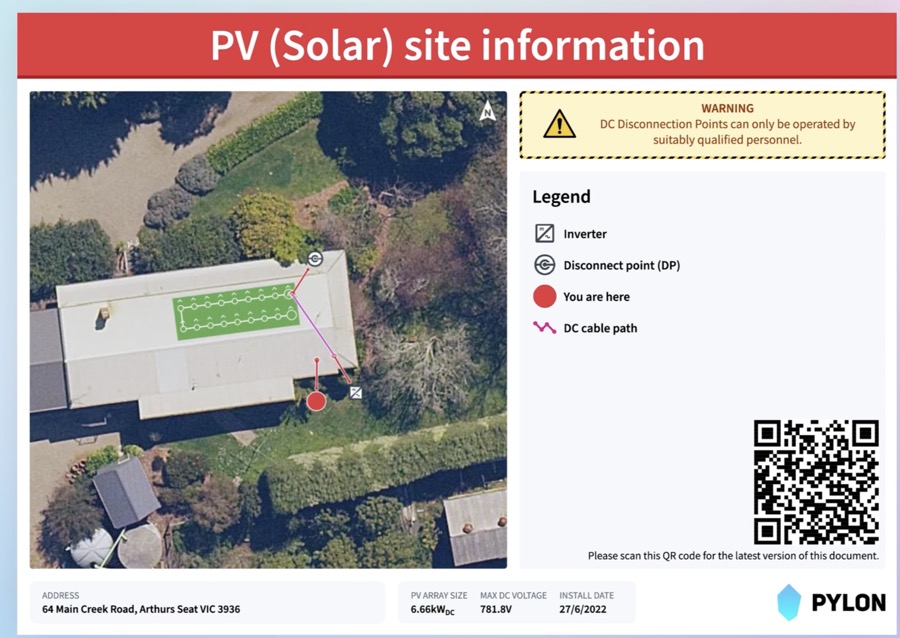

6. Use Labels For Easy Access To Info

The best solar installers ensure they have their documentation obligations in order. Using technology such as QR codes on the PV Site Information label is a neat trick. Scan that code, and it takes you to a handy document with all your post-installation info that is easy to amend if the system is altered. It’s all about making things easy and accessible, especially in emergencies.

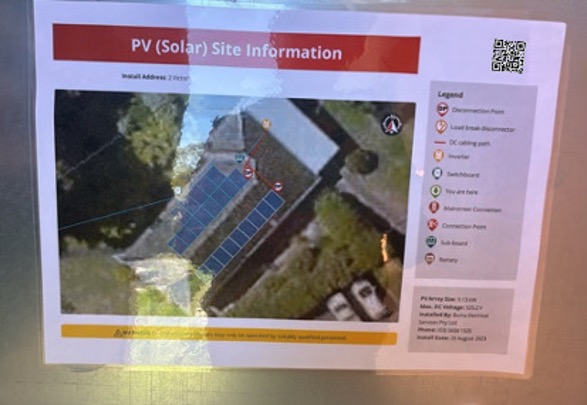

This PV Site Information label has been premade, is laminated & has accurate information. The QR code links to all the system information.

This QR code works – and goes to a demo account.

Wrapping It Up: Solar Labels Matter

In the world of grid-connected solar, labels are more than just stickers; they’re essential markers for safety, compliance, and longevity.

For those in Australia looking to invest in a solar power system, understanding the critical role of labelling can be your game-changer in making a wise choice of installer.

And for the installers out there, perfecting this can set you apart as a top-tier professional. While the industry has room for improvement, excelling in this seemingly minor aspect can be your quick win against the competition. So, let’s shed the outdated views on solar labelling and recognise its importance for a brighter, safer solar energy future in Australia.

RSS - Posts

RSS - Posts

A few good points in there, thanks. But why is it that the standards are not in the public domain? If someone has an interest in a standard they should have the chance to read it. It could save lives or raise awareness of safety or even just functional aspects. There are many people who are generically highly qualified in technical subjects though not working in a relevant profession. It would help them a lot to be able to see the standards and make sense of the rules that govern the trade. Should we start a petition to make standards public by default?

Agree 100%. Australian Standards should be free to all: https://www.solarquotes.com.au/blog/australian-standards-cost-free/

Hear. Hear.

Great to hear this said.

I included in my original letter to the Battery Installation Contractor an instruction about labels, with some specific comments. BUT the contractor DIDN’T label things properly, so I paid most of the bill but withheld $1,000. It took him 6 months to label the switchboards, circuits Isolators etc and finish wiring the Changeover system as I had requested (in writing), but I still ended up with this standard labels where they didn’t bother to insert the Isolator locations!

Labels are vitally necessary for :

1.Operation (Switching things OFF and ON normally,

2. When something unusual happens eg the Grid goes down, and for

3. Emergencies; maybe you can restore power, or maybe you need to ISOLATE your system for SAFETY.

Keep up the good advice,

Another point not mentioned – graphical labels. In a former life I had an employee who couldn’t read. When I took over my dads engraving business I made my labels in line with this employees needs.

It would be very hard for a solar installer to identify this need in a client, My labels have the same format picture of a label engraved onto the shutdown procedure.

If the installer takes the time to talk a client through the shutdown steps, the label, for example, on the

GRID

Supply

Main

Switch

has a matching label engraved picture on the shutdown procedure.

I would like to have a sign at the main access point to my roof space as in your photos. Are these readily available form electrical wholesales or do they require special suppliers?

You can buy good quality ones from PV Connections:

https://pvconnections.com.au/product/custom-disconnection-point-solar-label-kit-colour-logo/

Made to order for the specific installation.

But what wrong with that?

My experience in industry was that EACH job/project required specific labels!

Unless life has changes in the last 10years there are plenty of companies that make labels, computer driven.

Regards

Lyn

Thank you Finn,

This company only sells 20 minimum. I am after a one off kit

Regards

Michael

https://www.ebay.com.au/itm/394448481583

Hi Michael,

If you can’t find what you are looking for. I run a small laser engraving business near Newcastle, but have shipped finished products worldwide. I won’t claim to be the cheapest, as my raw materials are UV Stable.

I won’t put up business name or contact details without site approval, but I am more than happy to make whatever you need with NO artwork fees, and NO setup fee – It is just materials (at cost), and the machine time to produce the label.

Admin – please advise protocol for posting details…

David – happy for you to post your business details here

Many thanks David for your generous offer,

Finn has found a supplier of one off kits on EBay. Thank you for your kind offer. My installers did supply essential signage. I can see that the warning for entry into the roof space is what I really need.

Hi All,

Please, I’m happy to have Davids business details for the occational small future job.

Lyn

Hi Pat,

As a Licenced Electrical Inspector, I would love your feedback on what steps can be taken against installers.

As an engraving business I have a choice of using (cheaper) indoor rated materials, or to use outdoor UV stable materials that cost more. With 2 pieces of material, 1x indoor, and 1x outdoor, I can’t tell you which is which unless there is a sticker on the sheet.

My point is that, when you inspect a new installation, and I love your comment that seeing good labelling sets the mood for the overall inspection,

Lets move away from AS5033 to AS4777.1 – section 6 for labelling

All signs required in this Section shall be—

(a) sufficiently durable for their purpose;

(b) constructed of appropriate and durable materials suitable for the location, and where installed exposed to direct sunlight, shall use UV stabilized materials;

(c) fixed in a durable manner appropriate for the location;

(d) in English;

(e) legible and in a letter size appropriate for the location;

(f) designed to have a lifetime greater than or equal to the service life of the IES;

(g) indelible; and

(h) visible, as required,

I see SO MANY installations where indoor rated red and yellow labels have been provided where, within 6 months, the red fades to white, and the yellow changes to black.

Does a + 12 month inspection need to be built into an already busy inspection schedule to check on the labels and to ensure they comply with: (f) designed to have a lifetime greater than or equal to the service life of the IES. Surely, if we even go with a system life of 5-10 years, in what world do labels that fade to white in 6-12 months comply???

There seems to be no interest in this area, and I don’t understand why this isn’t targeted…

Sorry for my rant, but the public deserve better. Your article puts forth a lot of good points, and I applaud you for covering the topic so well