Under 10 degrees tilt? Try groovy solar panels made by Winaico (and others).

It’s really bucketing down here in Queensland right now. I’m relieved because until this evening there was a remote but real possibility of everything going all orange and wavy and really hot. I have friends coming over from Taiwan and I’d be most dreadfully embarrassed if all we had to offer them was a fine selection of ashes.

The rain pounding on the solar panels over my head is giving them a good clean. They’re at an angle of 22.5 degrees, so water easily flows off them and carries away grime. The most common roof slopes in Australia are 22.5 and 15 degrees, but 10 degrees is enough for water to run off and prevent it pooling on the panel glass or at the bottom edge of the frame.

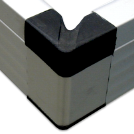

Panels mounted at under 10 degrees are less likely to remain clean from only rain falling on them. Using double glass panels without frames can help, but are an expensive option as they usually require yearly maintenance to check the tension on the clamps holding them in place.1 One lower cost option is to use solar panels with corner water channel drains.

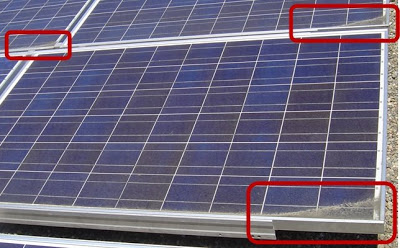

Solar panel corner drains on — in order — Winaico, Panasonic, and SolarWorld America panels.

Why Installing Panels At Under 10 Degrees Is A Dirty Deed

When solar panels are laid down at an angle of less than 10 degrees they tend to get dirty. When the angle is low, rain water can pool up at the bottom edge of the solar panel or if it’s very low it can pool on the glass of the panel. Worst of all is if the panel is installed completely flat and the frame acts as the walls of a container, creating a solar panel swamp.

Most roofs, even ones that look flat, have at least a slight slope so a swamp is unlikely to form, but pools of water can still accumulate. This is a problem because dust and leaves and other grot can collect in them and when the water dries it will often be stuck fast. Normally when a leaf falls on a solar panel it’s blown off soon enough, but when it’s sitting in a pool of water that dries up it can get firmly attached.

Dirt accumulating in this way can greatly cut solar energy production. The Googlarians at Google headquarters near San Hose-ay in California, a location with rainfall and climate roughly comparable to Adelaide, found dirt halved the output of solar panels that were installed flat on carports after 15 months. After giving them a good clean their output was cut by one-third after 8 months. But for panels mounted on sloped roofs, rain was sufficient to wash them clean.

A dirty picture from Google showing dirt left behind in panel corners by evaporating water. (Image: Google, like I said.)

Solar Installers Must Warn Home Owners

The problem with solar panels getting dirty when they’re installed at under 10 degrees is so bad the Huge Mouthful Guidelines, sorry, the Clean Energy Council Install And Supervise Guidelines For Accredited Installers, states in section 7.1.4:

When the guidelines use the word “shall” it means it’s mandatory, so installers must inform homeowners about the dirt collecting propensity of panels at under 10 degrees and explain they may need regular cleaning. This shall be done before they’re installed.

The Mandatorian

Corner Channels Can Help

To keep panels clean, the best thing to do is install than at a tilt of at least 10 degrees. If this isn’t possible or desired, ways to limit dirt build are:

- Use frameless panels and pay the expense of annual maintenance (re-tightening the clamps) if required.

- Use panels that are particularly dirt resistant, such as ZNShine’s graphene coated panels.

- Use solar panels with water channel drains in the corners to let the water flow free and, hopefully, carry away dirt.

As this article is about corner water channels I’m going to concentrate on them.

Solar Manufacturers With Corner Channels

I’ve only found three solar panel manufacturers who have put water channel drains in the corners of their panels – and the American one appears to have stopped:

- Japanese Panasonic

- Taiwanese Winaico

- Americanese SolarWorld

Panasonic

Panasonic’s water channel looks like this:

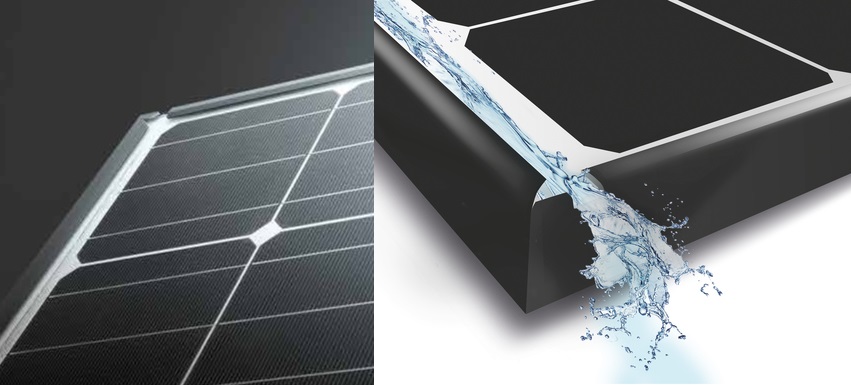

These channels may work just fine, but that is not real water in the illustration above. Water has surface tension that prevents it from behaving that way. Either Panasonic made a giant solar panel that allows water to pour through its channels like a river or it’s just CGI bullshit.

New Panasonic panels are rarely seen in Australia these days. Unless you specifically order some from Japan you’re going to have a hard time finding solar panels with these channels.

Panasonic no doubt created the channels because Panasonic the Hedgehog is afraid of water.

Winaico

Taiwanese-made Winaico solar panels are available in Australia and they have an office in Sydney. While two of the panels listed on their website don’t have corner channels, I’ve been told only newer model panels with corner channels are likely to be available in Australia from early this year. Unlike Panasonic’s, their channel goes diagonally through the corner of a panel and looks like this:

Now you might say, “Hey! That water channel’s at the top of the panel! It won’t do any good!” But not to worry, manufacturers have done the responsible thing and put a channel in each corner rather than just having two and letting installers sort it out. Very thoughtful of them.

Winaico’s channel is part of a solid aluminium corner piece called an L-key that looks like this:

This episode of Winaico Street was brought to you by the letter L.

It makes the frames very sturdy and Winaico are quite proud of this, as they boast:

While they have mastered the art of sturdy solar panel corners, they haven’t yet mastered the art of not using black text on top of a black background. If you can’t make it out, the last word in the image above is “typhoon”. This means they should also be resistant to cyclones, just so long as the fact cyclones blow the opposite way doesn’t cause the panels to unwind.

Winaico says they have a world wide patent on their water channel. I think they mean for their specific L-key corner piece design, because if it’s for channels in general that’s patenting the bleeding obvious. After all, I dug a channel to let the rain water out from under the house this morning and I didn’t have to fight off any patent lawyers to do it.

SolarWorld America

SolarWorld was a German company that went bust, came back, and then went bust for good. The SolarWorld America factory soldiered on for a while but was bought by US based SunPower in 20182 and by early 2019 production had been changed over to SunPower P-series panels, so it appears panels with SolarWorld corner channels are no longer made. But so few solar panels have channels I decided to include them anyway.

SolarWorld America’s channel looks like this:

You might think that looks a lot like the Winaico panel channel, but its construction is different. The part with the channel is plastic and sits on top of the frame corner. Because of this, with sufficient abuse, it can come loose. Winaico seems to think it’s nowhere near as good as their design, although I suppose it is possible they are biased.

It’s easier to see that it’s not a solid corner piece in this picture:

Dirty Videos

Winaico has made a video of their corner water channel in action and put it on youtube:

At the moment it has a total of 102 views. Let’s see if we can get that up to at least 103.

In the video there is a long shot that shows the water flowing through the channel. But when it changes to a close-up we see the water building up above the channel due to water tension and then it flows down the solar panel frame besides the channel instead of in it. This is pretty normal behavior for water. We can’t predict exactly what it will do, which is why I never drink the stuff.3 But it does help water to flow off the panel and carry away dirt, even if it doesn’t always flow where you’d expect. I’m afraid I don’t know what angle the solar panel is in the video. I considered using SOH CAH TOA to work it out, but I’m not sure that would be accurate.

Update: Winaico has told me the angle of the panel is only 3 degrees.

Note the tiny solar panel in the video is not available for purchase. It’s just a baby sized one they made for easy testing and filming of their corner drains. Here’s another video of it in action:

Corner Channel Drains And The Future

Corner channel drains are a straightforward way to improve solar panels, so I expect they’ll become more common in the future. This change may be gradual, as panel frame production probably can’t be easily altered to include them. Hopefully tests will soon be performed under real world conditions that will show just how useful they are at keeping panels clean.

Besides being a cheaper option than frameless panels on gentle slopes, they may also be useful for installation at over 10 degrees anywhere water is likely to remain at the bottom edge of a solar panel for long periods, such as damp and cloudy locations like Tasmania or where they are heavily shaded.

Footnotes

- Because the clamps are on glass the tension has to be within a tight range — but not too tight. ↩

- Since then, SunPower has apparently sold the factory and leased it back from whoever they sold it to. This may have been a smart business move, but it is exactly the sort of nonsense companies engage in when they are in financial trouble. Yingli has been leasing their own production line for years. ↩

- I always freeze water into solid ice before ingesting it so it won’t do anything I can’t predict with Newtonian physics and a slide rule. ↩

RSS - Posts

RSS - Posts

I’d like to open a discussion on the topic of creating large solar farms in Western Australia to make use of their later runtime to feed East coast cities at peak consumption times. I don’t have sufficient tech knowledge nor research capacity to answer my own questions on the topic.

In simple terms, we have a situation where WA is 3 hours behind the eastern seaboard. Our peak consumption time of early evening coincides with WA peak generation potential. Time shift the energy. I understand constraints inherent in transmission loss but how severe would such losses be. Would such losses render such a scheme unviable ? How does this compare with a scheme to send our energy undersea to Singapore ?

The major problem is the expense of long distance transmission. Jakarta is 3,000 km from Perth and Singapore is 3,500 km from Darwin. Sydney is 3,200 kilometers from Perth and 2,000 kilometers from Darwin. To me, building transmission lines to Singapore or Jakarta does not look like it will pay for itself. For the east cost of Australia the distance is comparable, but the wholesale price of electricity is far lower than in Singapore so, again, it’s very unlikely to pay. Given the falling cost of battery storage, I doubt the west and east coasts will get connected by transmission lines.

Ron – wouldn’t the West Coast connection only have to be long enough to join it to SA’s portion of the grid? In other words, about half the distance to Sydney. In doing so, it would also enable connect of the wider WA grid to foster development of wind, solar and pumped hydro across many areas of coastline or inland which are sparsely populated, suitable for each type or combinations thereof and have a low land cost?

I think CSIRO has done some modelling on a fully connected grid across Australia plus distribution of generation capabilities across time and climate zones? Perhaps this is a much more sensible use of public funds than building a polluting, high cost and unprofitable coal fired power station. If only.

Powerlines from WA would only have to reach Adelaide, but then Adelaide’s connections to other states would have to be improved so the high population states to the east could take full advantage of it. On the other hand, since SA is planning to build an interconnector to NSW maybe a transmission line from WA to Adelaide could provide a significant amount of power to the eastern states in the late afternoon and evening without further upgrades.

Not even Adelaide, I suspect, but just to Port Augusta perhaps? That’s about 200kms north. There used to be a power station there so i think there would be good interconnections from there.

You should reach out to engineers who perform cyclone testing on solar modules. These sorts of modifications to module frames severely impact the test results and you can pretty much forget installation in the NT… It’s bad enough panel frames are now 35mm/40mm – they can’t withstand the same pressures they could when the average frames were 40mm/45mm+

Minor modifications to frames can definitely have major effects on their strength, but I wouldn’t be too concerned about Winaico’s channels. Typhoon resistance is a bugaboo of theirs and apparently their channeled panels test at 5,400 Pa positive pressure and 3,600 Pa negative. They say that’s their maximum test load.

WINAICO’s full range of products has been tested with the in the Dynamic mechanical load test.

Dynamic mechanical load refers to a change in pressure, due to strong winds and squalls, for example, in which WINAICO modules withstand 5,000 Pa for 1,000 cycles, which simulates the strongest possible typhoon, which effects of more than level 17 of strong wind on the Beaufort scale. The test criteria were carried out according to IEC TS 62804-1:2015.

Here’s a copy of the testing results

http://www.winaico.com/fileadmin/2016/Certificates/2019/ITRI_ML_6500pa_WSP-325MX_03282019.pdf

For another neat video on this topic here is a link.

“When the guidelines use the word “shall” it means it’s mandatory, so installers must inform homeowners about the dirt collecting propensity of panels at under 10 degrees and explain they may need regular cleaning. This shall be done before they’re installed.”

Yeah and good luck trying to prove they didn’t !!!

I have mentioned again and again, and I will again.

A hydrophobic Glass Cleaning Product will not only help the water run off these Panels Better, But the existing Panels that are on the market! These products also help the water to not only STOP sitting on the Panels, but the Water and contaminants that do, do not mark of stain the Panels what ever degree they are installed at.

But by saying that i am happy that you are finally accepting that there is a need to tell customers that Annual Cleaning is required for the installations, I live and work in an area with high contaminants in the air, and even the Panels on 24 Degrees are not getting cleaned by the rain! Even after all the rain we are getting at the moment, The Panels I clean are still baked on with contaminants in the air.

Hi there,

I’ve just moved to FNQ, near the coast, so deffo in cyclone country. My house roof is almost flat over the entire house, so this article is of great interest to me. My question is – how does the price of WINAICO panels compare to the bog-standard ones I’m likely to be offered up here near Port Douglas? WINAICO get good reviews, from what I can see, on lots of other sites. I’m looking to get solar installed asap, but the installers I’ve talked to just want to install, I think, whatever is easiest for them and they make most money out of. I get it, they want to make as much profit as possible, but I’d like to make informed decisions about what is best for me. Thanks for any input.

Hi Belinda – here’s a Cairns based Winaico dealer: https://allenergyqueensland.com.au

Thanks so much.

I have spoken to 4 installers (in Darwin NT) and all of them said that my 5 degree pitch roof is perfectly fine for panel installation. I even mentioned that this site said 10 degrees was minimum and they basically said it wasnt. None of them suggested anything about a mandatory warning.

What gives?

In most of Australia — definitely here in Adelaide — a slope of 5 degrees can lead to dirt build up. But I have no problem believing rainfall in Darwin is heavy enough and frequent enough to wash the panels clean. They are supposed to give a warning, but if it’s not a problem in the area it would explain why they don’t.

Is there any one who uses solar panels to obtain electricity as well as shading? Can you explain how you drain out rainwater without entering it into the shaded area?