An industrial solar panel recycling plant built in Germany as a pilot project has performed well according to the European Commission’s Community Research and Development Information Service (CORDIS).

German engineering company Geltz Umwelt-Technologie built the facility under the ELSi project, an EU funded initiative.

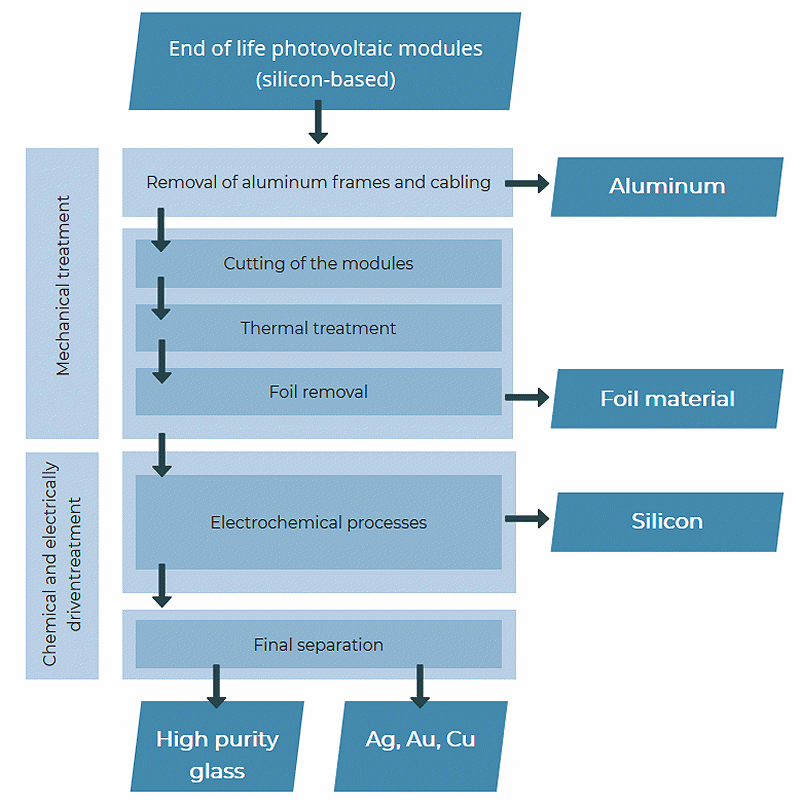

While the glass on a solar panel and its aluminium frame are relatively easy to recover, polymers used to bond a module’s various other components together can make recycling a headache.

“Up until now, there has not been any technical solution to recycle and separate the valuable materials from the mixed scrap. The critical step in the recycling process is therefore the destruction of the polymer layers,” said Fabian Geltz.

The ELSi system uses an energy-efficient pyrolysis process to dissolve the polymer layers, enabling successful recovery of aluminium, glass, silver, copper, tin and silicon in a pure form.

The ELSi Recyling Process

Image: ELSi project

The industrial pilot facility has the potential to process up to 50,000 solar panels per year (around 1,000 tonnes of modules) according to a report recently published by CORDIS. It says the process used results in a minimum yield of 95% of materials reclaimed.

The ELSi plant isn’t the only game in town. Back in June we reported a commercial solar panel recycling plant had opened in France, operated by waste management giant Veolia. That facility is expected to recycle 1,300 tonnes of material in its first year and up to 4,000 tonnes by 2022.

“Once recovered, the materials are redirected to various industrial sectors: the glass, 2/3 recovered as clean cullet is used in the glass-making sector, the framework in an aluminium refinery, plastic as recycled fuel in cement works, and silicon in precious metal1 sectors,” says Veolia. “And as for the cables and connectors, they are crushed and sold in the form of copper shot.”

In France, 53,000 tonnes of end-of-life solar panels wound up on the waste market in 2016 and 84,000 tonnes in 2017.

Averting A Waste Crisis – For Planet And Profit

Solar panel recycling is a pressing issue that could evolve into a major waste crisis if necessary action isn’t taken.

Back in 2016 the International Renewable Energy Agency warned at the end of that year, cumulative global PV waste streams were expected to have reached anywhere up to 250,000 metric tonnes. While good quality solar panels have a service life measured in decades, at some point they will fail or need to be retired. IRENA’s forecast put waste amounts by the 2050s at 5.5-6 million tonnes; almost matching the mass contained in new installations (6.7 million tonnes).

It’s a big challenge, but one that also provides significant opportunity.

“Recycling or repurposing solar PV panels at the end of their roughly 30-year lifetime can unlock an estimated stock of 78 million tonnes of raw materials and other valuable components globally by 2050,” stated IRENA’s report. “If fully injected back into the economy, the value of the recovered material could exceed USD 15 billion by 2050.”

While Europe seems to be getting its act together through initiatives such as PV-Cycle, as for what’s happening here in Australia, there doesn’t appear to be much progress on this front yet. We reached out to Australia’s only panel recycler, Reclaim PV Recycling, after our last related story, but we didn’t hear back from the firm regarding the status of its operations.

RSS - Posts

RSS - Posts

Just wondering, what does the 5% that’s not recycled consist of?