Some months ago, I penned an article about how critical the humble MC4 plug is to solar PV systems. Today, we’ll explore the failures that these plugs often present and how to avoid them.

Read back on the potted history of connecting solar panels. Or read on for some of the horror stories I’ve found myself.

Water-Sealed For Safety

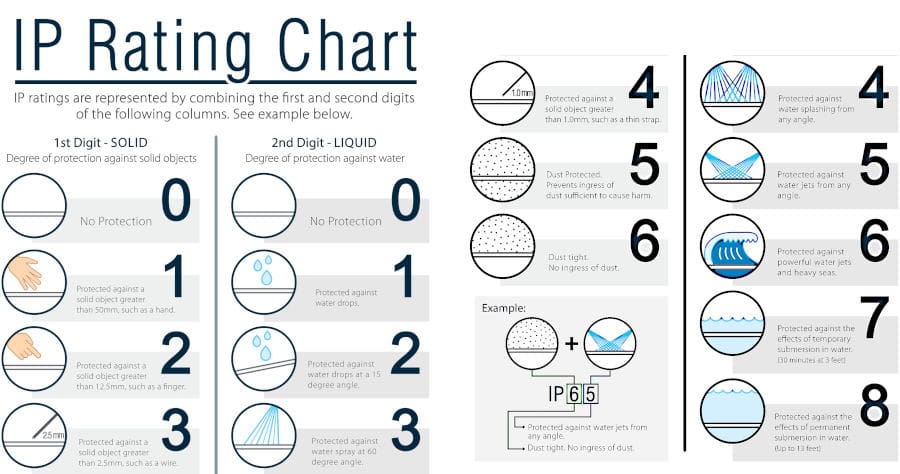

Genuine Staubli MC4 connectors are rated for ingress protection to IP68, so they’re sealed like a diving watch.

However, your wristwatch doesn’t carry up to 30 kilowatts of power through it, at 1,000 volts DC.

IP ratings explained.

Cheap Plugs Are Expensive

The litany of failures you’ll see in this blog post are primarily because they’re the cheap imitation plugs that come with cheap solar panels and don’t have the same level of water resistance.

Thankfully, most panel manufacturers now specify genuine Staubli MC4 plugs, which have become the default industry standard.

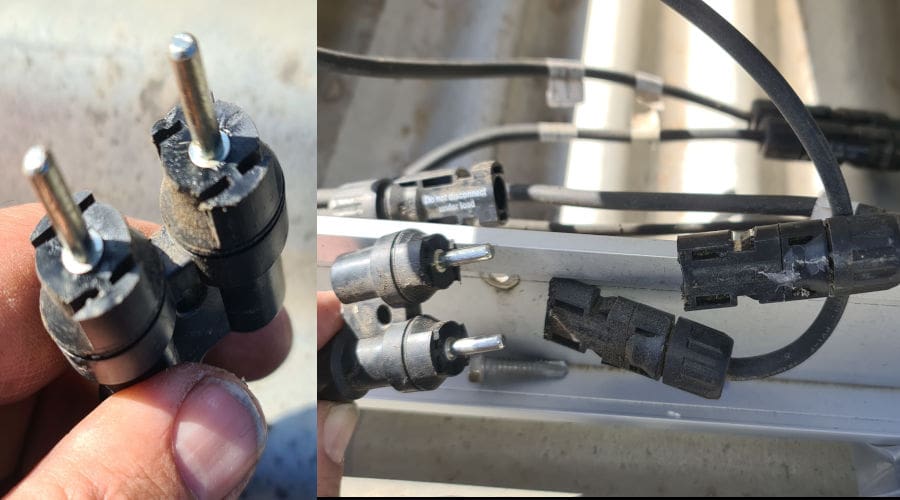

The brownish stain on the parting line shows this plug was filled with preservative grease before it was assembled. However, when the gland nut cracks open, you can’t expect it to stay sealed

This plug was so severely corroded I had to break it apart with pliers.

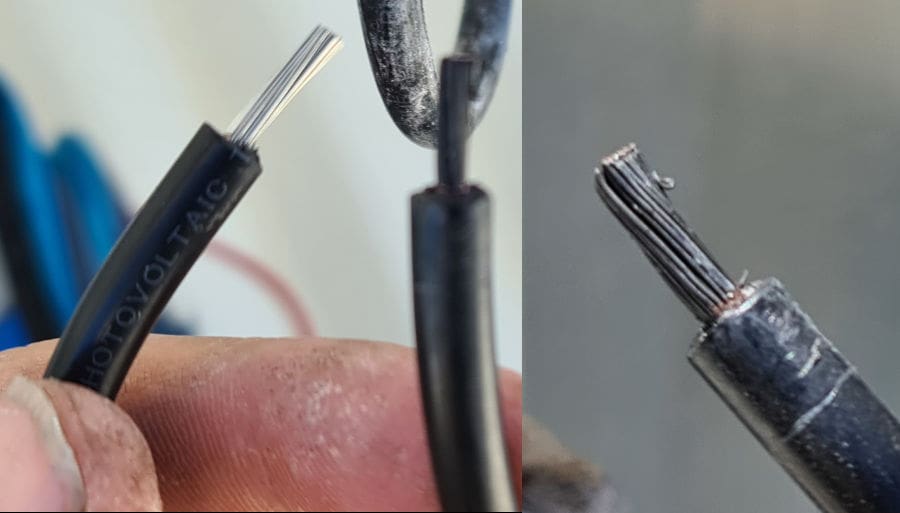

When water leaks in through MC4 plugs, it can then wick down along the copper strands and cause corrosion inside the cable.

On this particular job, we had to scrape the strands to get them shiny and bright, then twist them, scrape them again, twist them, scrape them again, and so on — just to get a good, clean, crimped connection on the new pin.

Bright tinned cable on the left. Strands corroded by moisture on the right.

Water Causes Earth Leakage, And Loss Of Yield

It only takes a small amount of water to leak in to cause a small amount of electricity to leak out. Then you have an earth leakage problem. It’s the same kind of issue that will trip the RCD safety switch in your house switchboard, except in solar installs, the inverter will shut down.

Legally speaking, this fault should produce an actionable alarm, like a buzzer or strobe light, but in most cases, an email alert is expected to reach the system owner. It’s a prime reason to ensure your solar monitoring system works and your WiFi remains connected.

This plug had been lying in a puddle, as evidenced by the tide mark and the green corrosion of the pin inside.

Substandard Plugs Fail Under Warranty

Some of the plugs pictured here belong to a job that every electrician in our company had visited at some point. It was situated in a marina, and the prevailing wind would carry salt water under a pitched angle frame, to the point I’d joke that these panels were basically installed in the ocean.

Monitoring demonstrated this system was pretty lazy. On a sunny day it might dry out by 10 AM and get going, but often it had earth leakage problems that meant it just didn’t work.

The customer complained to us, we complained to the manufacturer, and they came back with a test regime that was highly impractical.

The cost of labour to remove panels, dip the plugs in a bucket of water for 15 minutes, and then test for insulation resistance was simply ridiculous. After multiple visits, hosing the array down, testing, and replacing pairs of plugs ad hoc, we were eventually given a budget to go through and replace all of them.

Variety of cracked and broken connectors (not genuine but supposedly compatible with MC4).

Branch Connectors = Bad Idea

Branch connectors, a kind of double adapter for solar, are sometimes used to create parallel connections. While they’re handy for low-voltage applications like caravans, they’re a terrible idea on grid-connected solar systems at hundreds of volts.

Many solar inverters can’t handle parallel arrays, but for those that can cope, I would insist on having all of the strings run from the roof right down to the inverter. This allows for proper electrical testing (and fault-finding) by the commissioning electrician on the ground.

I’ve inspected a new system that lost 25% of its yield for months simply because one connection was missed on the roof. One-half of the array gave a voltage and current to test at the inverter. The other half, which should have been connected in parallel, was simply left unplugged at the branch.

Cracked branch connectors that fell apart.

Mixing Plugs Is Not Allowed

These images are a case in point as to why you’re not allowed to mix different brands of MC4 plug.

They might look compatible; they might plug together; that doesn’t mean they match. And that could cause serious issues — including the risk of fire. Energy Safe Victoria has a great guide on this subject.

Overheated, melted, bent, mismatched and burnt open.

As with every rule, however, there is always an exception, as shown in this excerpt from a Staubli manual.

Source: Staubli.

Raising Standards In Solar Installation

With this observation, I might not win any friends in the industry, but many good installers agree that we shouldn’t be leaving MC4 plugs exposed.

I know some excellent instals look like this, but — while it’s not a compliance failure — it doesn’t make any sense for crucial components to be left exposed to the weather.

IP-rated or not, leaving plugs in the gap like this rankles my sensibilities. At least they’re not lying on the roof.

Cable Management Woes

Solar cable management has also always puzzled me. In the bad old days we used to throw wiring anywhere under the array. Picture the under-the-botnet mess of a 70’s American car.

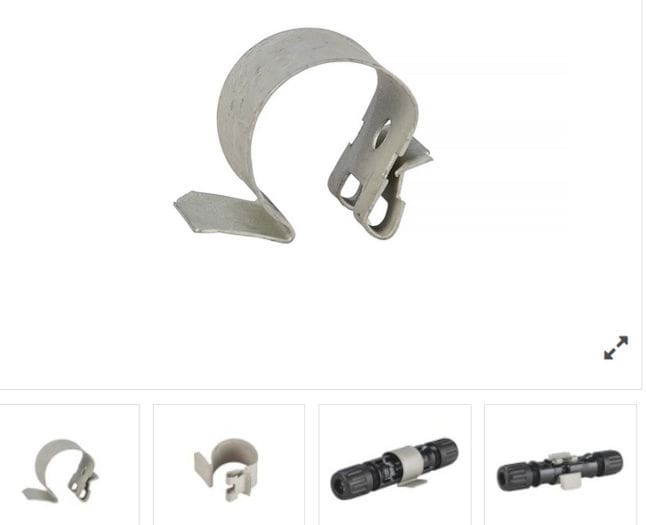

Japanese car makers forced drastic improvements in standards simply by securing wiring and plumbing properly, with clips, clamps and ties everywhere.

MC4 clips from PV Connections. I think these should come standard with every panel.

By comparison, solar hasn’t got a systemic cable-management solution. We have to rely on people not only knowing what they’re doing but caring about the finished result. It’s great when you’ve got a good installer, but it is often a recipe for disaster if price is the deciding factor.

While I take great pride in putting wiring out of harm’s way, some people I’ve worked with… well, sometimes I think they were just trolling me.

Some people just don’t care.

Some Better Examples

Sometimes, there’s no perfect option for tidy cabling, and installers must find the best compromise.

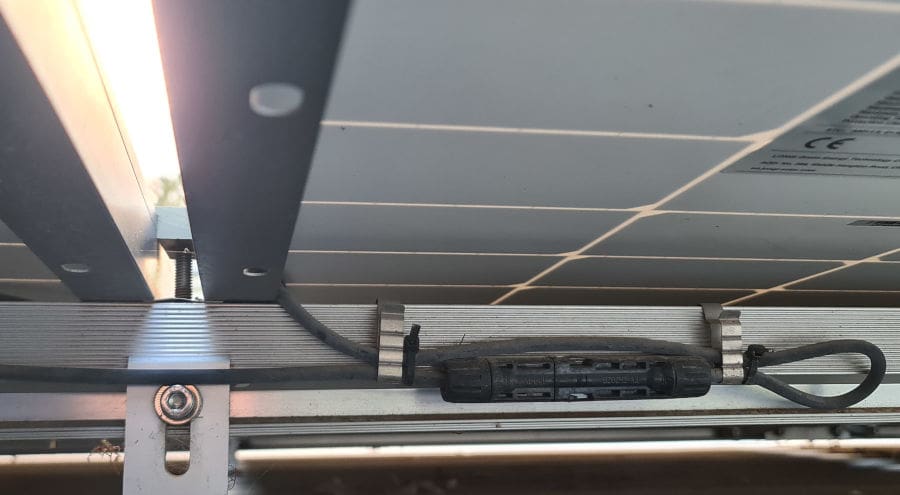

The installation below features a panel mounted in landscape. A plug laid in the panel frame would sit in a puddle of water, ending up looking like the cover image for this post.

Stainless cable clips on vertical mounting rails.

Below, we see an MC4 plug hooked to the rail, away from UV damage, out of the weather and out of harm’s way. Hooks are great but these ones will only work on one side of the rail, which can a pain.

Plastic ties tame this cable so it doesn’t spring from the hook. Once set in place, they won’t go anywhere.

Most installers simply clip wires onto the panel frame and try to use up excess cable wherever they can. When panel makers remove the lip from the short side of the panel, it can be challenging to do this properly, so you can end up with droopy loops of cable.

Having a top edge to clip limits your options.

Below, we see the plug tucked away safely in the top of the panel frame. Primary support of the string cable along the mounting rail is a stainless cable tie, with supplementary plastic ties further along (according to the rules, primary supports must not be plastic).

Plastic ties are claimed to last 15 years, but they get brittle and fall off, so I would suggest more stainless ties for this job.

Stainless clips hold the cables against the panel frame. Plastic ties help keep things in position before everything takes shape.

The Devil Is In The Detail

If you’re dealing with solar salespeople, this level of detail might be beyond them. However, the best operators — the kind that send an actual electrician to quote your job — will understand what you’re looking for and why it’s important.

They understand that earth faults can cost a lot of yield and gobble up a lot of time in diagnosis. That, in turn, creates friction with customers and can even land people in civil tribunals.

Proper craftsmanship saves a lot of angst.

You can ask to see some proof of a proper finish without being overbearing. And if you can get your installer to produce that evidence, let me know how you did it. They can be a bit cagey.

RSS - Posts

RSS - Posts

I am wondering: should I get up on the roof now and check that all the plugs look ok and no cables are dangling etc? Articles like this one are useful but can also instill fear about the quality of the installation one has. Also, I cannot tell whether the installers years ago used genuine plugs or not. Is there a risk they may have not, or does this mainly apply to self-installed systems where people bought the cheapest material they could find on Ali or somewhere?

The rules around matched MC4 plugs have been in place for many years now, but even so the mismatch of “compatible” plugs isn’t a guarantee of failure. It’s probably just a reflection of risk averse rule makers. 5 years is a good inspection interval.

Hi George,

Thanks for the opportunity to debunk some disinformation and FUD.

From the article;

Because EVs are on average 30 per cent heavier, brakes and tyres on the battery-powered cars wear out faster than on standard cars.

Except brakes on an EV don’t wear out faster because regenerative braking means they simply do less work. For example, my own Outlander PHEV still has 40% of it’s original factory fit brake pads at 117,000km, compared to my diesel Transporter that had all pads and rotors replaced at 75,000km

Emission Analytics found that tyre wear emissions on half a metric tonne of battery weight in an EV are more than 400 times as great as direct exhaust particulate emissions.

Ignoring the fact that ICE vehicles have tyres too.

For reference, half a metric tonne is equivalent to roughly 1500kg.

This is the real kicker, you don’t get a much better example of “SkyNews” quality opinion than saying 500kg = roughly 1500kg

They’re so lazy and inept they can’t even edit an american article referencing pounds to just remove the redundant conversion.

Of course the thrust of the matter is that EVs emit half the CO² and tyres should be made from better materials; but it’s not like the Murdochracy to let fact get in the way of a good piece of resurfaced clickbait.

Well case in point – Tesla Model 3 RWD – 1761Kgs. Toyota Camry Hybrid – 1655 kg. Hmmm – if my maths is any good that’s a total weight difference of 106kgs. Hardly world changing for tyre wear. I wonder how much a Land Cruiser weighs? Up to 2,455 kg without a van on the back or a bull bar. Yep – they aren’t good for the environment either.

It’s a ridiculous argument when Australians have a preference for big, heavy vehicles any way.

I’m not a fan of big heavy, inefficient EVs either. Hopefully the market will bring more small and efficient EVs to market. In the meantime at least Tesla is addressing the issue with a much lighter body to compensate for the additional weight of the battery pack.

Yeah this is just the latest pivot from the FF Industry and the Motor Vehicle industry (then clickbaited by all of the Murdoch media around the World).

They have now realised they are losing the war against EV adoption (and electrification in general) so have pivoted to slowing down the adoption (and hence extending FF proifts) for as long as possible.

They seem to have these sorts of articles on a carousel

Bad indirect emissions

Bad Mining practices

Bad end of life consequences for EV batteries

Spontaneous Combustion of every 2nd EV on the road

Range Anxiety coupled with holiday queues and out of services chargers

No local charging options for onstreet charging

Craig

OMG. There are so many holes (read lies) in the article, that it’s just incredible.

However, it’s news.com, so entirely expected.

ROFLMAO

To be fair(er), I think on a re-read of the article they were NOT ignoring the fact that ICE vehicles also have tyre wear. It’s pretty clear they were comparing the EXTRA tyre wear emissions of an EV (over those of an ICE, due to the extra weight), wirh the tailpipe emissions of an ICE vehicle.

They acknowledge, I think, that this comparison does not include CO2 comparisons.

Many years ago the Company I worked with were certified to do vehicle tailpipe emissions testing. We were asked to test a big V8 American vehicle (then fitted with an exhaust catalyst), and were AMAZED at the HC, CO, and NOx readings, a small fraction of those of our local (not then catalyst fitted) 4-cylinder vehicles. We also demonstrated a small ICE (with catalyst), that had tailpipe emissions actually LOWER than that of the ambient air it was breathing! i.e., it would “hoover up” the atmosphere while driving (not including CO2)! We felt at the time the then newly introduced cabin air filters in cars was a message that the manufacterers had ‘given up’ futher emissions reductions.

But of course, the article did not recognise that EV drivers seldom use their mechanical brakes.

And as a lowly engineer, I have always thought 1 metric tonne was EXACTLY 1000 kg (by definition).

But tyres DO emit a lot of nasty particulates, I understand Cadmium, a toxic heavy metal, included (unless more recently removed).

Just as an aside – what type of domestic roof are the easiest to install panels onto?

Corrugated steel? Klip-lok? Trimdek?

Hi Dale,

Probably corrugated iron, because you can see the screw lines. Some deck profiles are a bit soft in my experience but all iron roofing is better than tiles.

Hi…I’m just curious as to why the push for Staubli connectors. The issue I have with them is the flimsy crimping wings….which actually are quite fragile. I acknowledge that the Slocable MC4 connectors require a specific crimping tool, but the solid pins are very robust, and once they are pushed in correctly in the connector body, they are there for good.

We had an old 3.5kw system and the inverter died right after the warranty finished (Lucky). To add to this the company which installed the system had gone into liquidation, so we had no other comeback on the installer company if anything else went wrong with the panels. The panels still have about ten years warranty still on them. I plan to sell them off to whoever might want some solar panels for an electrical cattle fence or a caravan/ camping. All of the electrical leads were dangling off the panels and most were actually touching the roof (colour bond metal roofing). My heart filled with dread every time it rained, incase on of the connecting plugs failed during a storm. Since the industry no longer made 3.5kw systems we decided to install a new 6.6kw system. This would negate any issues of compatibility/ warranty or other problems with putting a new inverter with older panels.