How close to the edge of the roof should your solar panels go?

In the past I’ve written about solar panel clamping zones which determine where, on a solar panel’s edge, you can place the clamps that attach the modules to their mounting rails. What I didn’t do was go into just where on a roof solar panels can and can’t be installed.

Depending on the roof mounting system used to attach the panels, there may be ‘exclusion zones’ where no solar panels are allowed. These zones exist because winds are strongest around the edges of roofs. Installing away from the roof edge reduces wind loading on the panels and makes them less likely to be damaged or even torn off in a storm.

I looked at five different manufacturers of solar roof mounting systems and was able to find Australian installation guidelines for four of them. Only two of these guidelines were available on manufacturer websites and so should be the most up to date versions available. Of the four systems for which I had installation manuals, two do not require exclusion zones, one has a small exclusion zone of 20 centimeters from roof edges, while another has a massive exclusion zone that can be over 80% of available roof space — but I assume this information is out of date.

Installers are required to follow manufacturer recommendations in order to comply with Australian standards. If they want to do anything that isn’t recommended, first a certificate has to be obtained from a structural engineer that states the specific changes being made won’t reduce the strength or safety of the installation. Even when manufacturer guidelines don’t require it, installers still need to leave enough space at the bottom edge of a roof so water flowing down solar panels doesn’t overshoot the gutter. It is also good practice to leave at least 20cm between panels and roof edges.

While I said some manufacturers don’t require exclusion zones, I will mention that air is automatically an exclusion zone and if any part of a solar panel extends beyond the edge of a roof, that is not a good thing, unless it is part of a special construction that a structural engineer has signed off on — but they never are.

Overhanging the edge is not allowed – unless you have a certificate from a structural engineer.

Roof Mounting System Basics

Australia is divided into four main wind zones ranked from A to D in order of increasing maximum expected wind speed. D is Australia’s most dangerous cyclone zone in Western Australia. While not an official description, you may find the following makes them easy to remember:

- A for All Right

- B for Beware

- C for Cyclones

- And D for you are going to Die

The more dangerous a wind zone is, the more roof attachment points are required to securely hold a solar power system in place on a roof. Some roof mounting systems may not be suitable for some wind zones, but all four systems for which I was able to find installation manuals are.

Installers are also need to pay attention to the surrounding terrain as maximum wind speeds will be higher if a building is surrounded by open ground and lower if it’s surrounded by structures and/or trees. Other factors that can affect the number of attachment points required are building height and roof slope.

With Roof Mounting Systems You Get What You Pay For

Tragically, it’s not always true that you get what you pay for. There are plenty of rip-off merchants in the world just waiting for their chance to overcharge you so they can make another payment on their diamond powered Lamborghinis. But for solar panel mounting, equipment price is a good indicator of quality. This is because it is bought and installed by hands on professionals who are obligated to return and fix any problems it may cause. This means if the components of a roof mounting system aren’t top quality then their price has to be low enough to to compensate for the possibility an installer will have to return to fix problems.

All roof mounting systems have to be certified, so no matter what is used your solar power system isn’t likely to blow off your roof in a storm. But there’s a big difference between getting top marks and just scraping by with a passing grade. If you pay more for quality your roof will be less likely to suffer minor damage or leak, which can lead to major damage. If you do have problems, the solar installer is required to fix them, but it’s a lot better to not have problems in the first place. To be clear, I am not saying you will have problems if you choose a cheap option, it will depend on what kind of roof you have and how carefully the installation is done, but the risk will be greater.

Australian Made Is Best

If you were to ask me which country makes the best roof mounting material I would say Australia. Two Australian manufacturers, Radiant and Sunlock, make some of the best gear around. These people know what Australian conditions and cyclones are like. So while I normally approve of destroying Australian industry1, just this once I will make an exception and recommend these Australian products to people interested in high quality.

10 Year Warranties Are Standard

Roof mounting systems generally come with a warranty of 10 years. Clearly this is a problem if you are expecting your system to last as long as the 25 year performance warranty most solar panels have. This is one more reason to select a high quality system as they are likely to last longer. All the mounting systems I discuss below have 10 year warranties with the possible exception of Radiant. While only 10 year warranties are currently mentioned on their website, in the past they have offered 15 year warranties2.

Popular Mounting Material Manufacturers

In Australia most roof mounting systems are supplied by the following manufacturers:

- Clenergy

- Grace

- Radiant

- Schletter

- Sunlock

- Titan

Clenergy

Clenergy is a Chinese company that produces lower cost mounting materials. Their PV-ezRack SolarRoof system can be used to mount solar panels on metal and tile roofs with slopes from 0 to 60 degrees.

The interesting thing about Clenergy’s exclusion zones is it doesn’t seem to have any. There’s no mention of them in its installation guide or this brochure. In this picture from the brochure you can see the panels get quite close to the edge of the roof:

Here’s another picture from the Clenergy brochure that shows the system is really edgy:

That system is close to all the roof edges. It’s so close to the bottom edge I hope during a downpour water flowing over those panels won’t fly over the gutter and miss it completely.

Grace

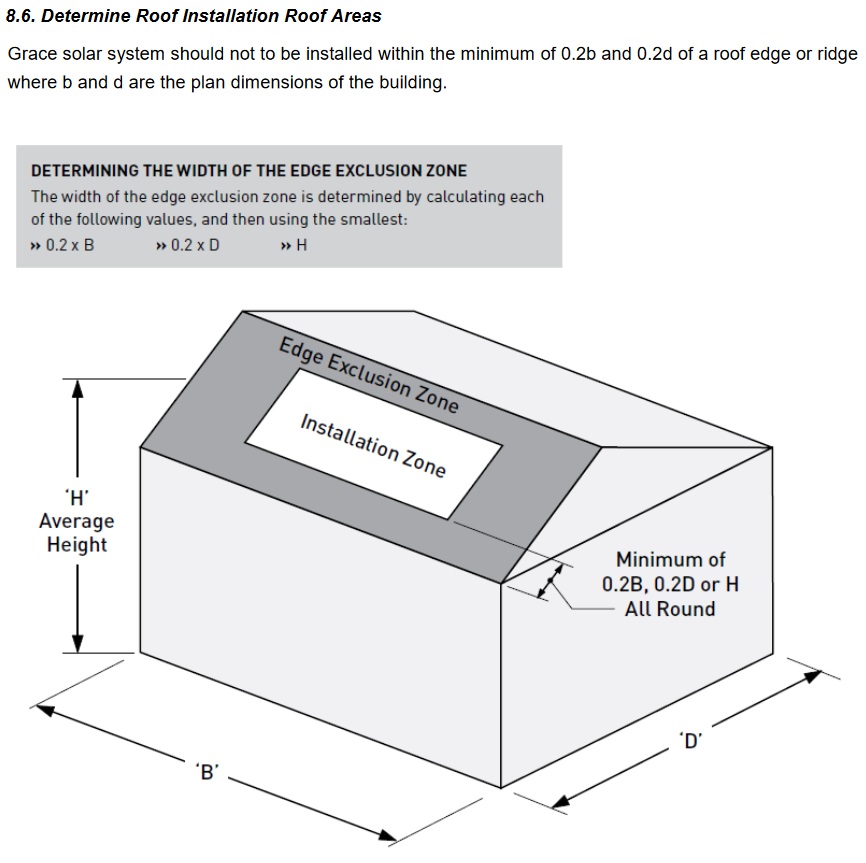

Grace Solar, also known by the rather insulting name Grasol3, is a Chinese producer of low cost solar panel mounting gear. On their website I couldn’t find any installation instructions or information on exclusion zones. Looking online I was able to find a PDF of their installation manual, but because it didn’t come off their site I can’t be certain it’s up to date4. It contained the following diagram on exclusion zones:

Their formula makes for very large exclusion zones. If a house has an average height (H) of 4m, a depth (D) of 10m, and a breadth (B) of 15m and the exclusion zone around the edge of the roof is equal to “Minimum of 0.2B, 0.2D or H All Round” as the diagram says, then the smallest figure would be 0.2D for an exclusion zone of 2m. If the roof has a 15 degree slope and consists of two identical rectangles then each would be 5.27m by 15m. With a 2m exclusion zone the area for panels on each half of the roof would be only 1.27m by 11m, which isn’t much and is less than 18% of the total roof area. That might have been fine back in the days when the typical solar power system was only 1.5 kilowatts, but it’s certainly not sufficient in these days of larger solar panel systems. While I approve of having some kind of exclusion zone, I think this is definitely taking things too far.

But what I find really interesting about their apparently huge exclusion zone is Grace uses this illustration on their website:

And also this one:

So as you can see, Grace has clearly changed their rules for exclusion zones since that diagram was published. Either that or they just don’t give much of a damn about them.

I have emailed Grace and asked them to clarify the issue5.

Radiant

Radiant is an Australian company that produces high quality roof mounting equipment6 It’s located in Capalaba which is just across Tingalpa Creek from Brisbane.

Unfortunately, I couldn’t find any information on exclusion zones in their brochure or website. But I did find this installation manual online. Note that because it’s not off the company site I don’t know if it’s up to date.

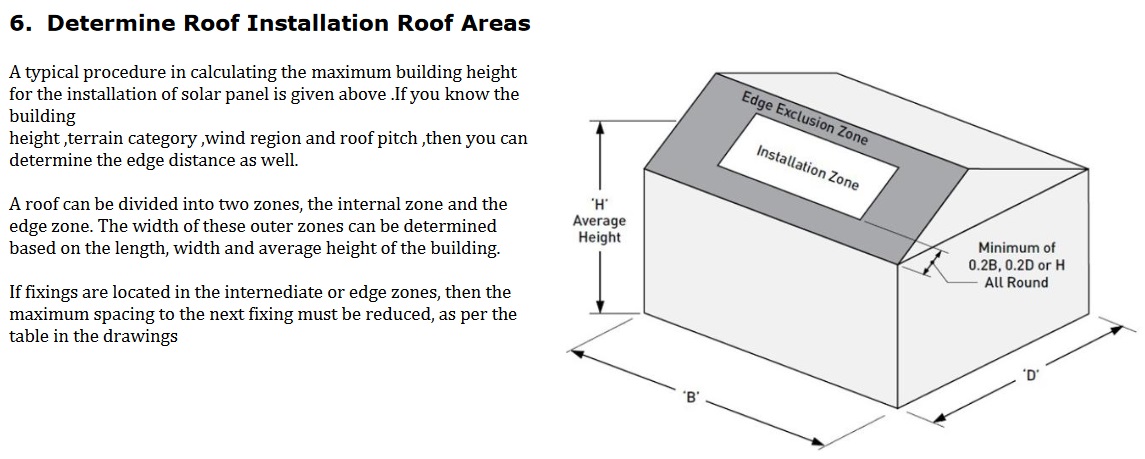

In the manual I found an interesting diagram with the words “Edge Exclusion Zone” written on it which I will reproduce below:

This diagram is interesting because it is exactly the same one as from the Grace manual. But while the Grace manual states nothing should be installed within the edge exclusion zone, for Radiant it’s not an exclusion zone at all. Solar panels can still be installed in what they call the edge zone, provided the rails that panels are clamped to have around twice as many attachment points to the roof as the rails in the internal zone. So provided rails are fastened as the installation manual recommends, panels can be installed up to the edges of roofs.

At the moment Radiant only mentions a 10 year warranty on its site, but as they used to have a 15 year warranty I am crossing my fingers they’ll soon go back to that.

Schletter

Schletter is a German company that produces high quality roof mounting systems in Bavaria and freely admits to using “lasers” in the process.

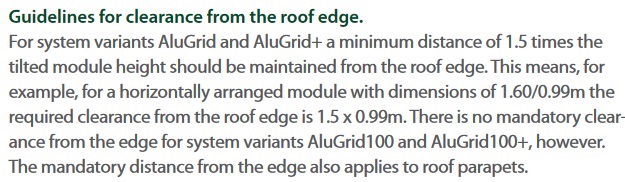

Unfortunately, I was unable to find any information specific to installing them in Australia. I searched their website for information on exclusion zones but only found the following information in a brochure on mounting systems for flat roofs:

Please don’t hesitate to look into it yourself if you want to understand Schletter better.

SunLock

Sunlock is an Australian company that produces high quality roof mounting components. Well, I say they’re an Australian company, but while they manufacture in Australia, SunLock is actually owned by Flex which is an enormous US company with headquarters in Singapore. But that’s fine by me. After all, if you can’t trust a globe spanning, multi-national corporation, who can you trust?

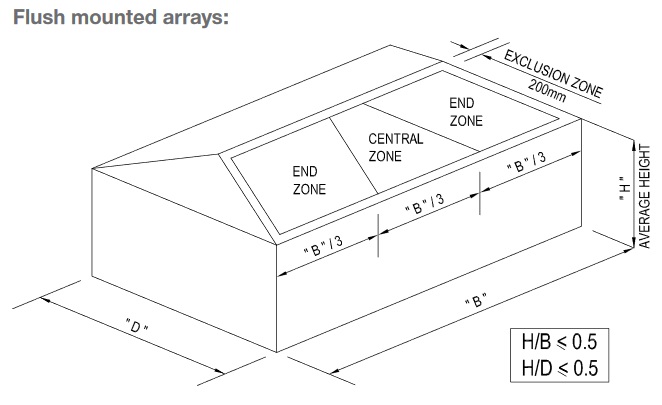

SunLock roof mounting systems do have an exclusion zone. It is displayed in this diagram from their installation manual which was very easy to find on their website:

Sunlock has a central zone where the rails that solar panels are connected to require fewer attachments to the roof than those in the end zones. These zones are surrounded by an exclusion zone where no panel can go, but rather than being potentially enormous, SunLock’s is only 20cm from the edge. That’s roughly the length of my manly hand or considerably less than the length of my first wife’s manly hand. Wind strength is greatest at the edges of roofs and so 20cm is enough to take some of the bite out of it without wasting too much roof space. As a result, this is recommended for all systems regardless of what installation manuals may say. It’s also a good idea to leave however much space is necessary at the bottom edge of a roof so rain running down solar panels doesn’t fly over the gutter.

I would like to thank SunLock for making all the information I was looking for very easy to find on their website. I’ll even go as far as taking my hat off to them. I’m not going to eat my hat, but I will nibble it a little.

Exclusion Zones And You

If an installer uses SunLock, Radiant or other high quality roof mounting systems you can be very confident they are motivated to do good quality installations. Someone using SunLock isn’t suddenly likely to get lazy and forget about its exclusion zone and someone using Radiant is likely to leave at least 20cm between panels and roof edges anyway as that is good practice. A possible exception to this is if a less conscientious installer is only using a high quality mounting system because the customer requested it.

If you are concerned about exclusion zones then it is best to bring it up with your installer before they put a system on your roof. You can check if an exclusion zone is required and if not, how much space from roof edges they are going to leave anyway. Note that if you push for as much solar panel capacity on your roof as possible, you may end up with panels that are closer to roof edges than is ideal. The customer isn’t always right, but they often get what they ask for anyway.

If solar panels have already been installed on your roof then it gets a bit more complex. If your installer violated manufacturer’s instructions by placing panels in exclusion zones than you can request they remedy the situation. Note that you are protected by Australian Consumer Guarantees regardless of what your written warranties may say or if they have expired. Also note you may end up with a smaller system if not all the panels can be made to fit.

Footnotes

- Politicians are always going on about saving Australian industry, but have any of them ever tried destroying it instead? This could be what we’ve been doing wrong all this time! ↩

- I’ve left Radiant a message on their answering machine. Hopefully they’ll call me back and fill me in on their warranties. ↩

- I can’t tell if companies in China don’t consult native English speakers before coming up with these names or if they do but the native English speakers are constantly taking the piss out of them. ↩

- I also can’t really be certain it’s not some kind of cunning forgery, but that seems a lot of effort to go to. ↩

- I’m not expecting a reply. ↩

- Here’s one positive review. ↩

RSS - Posts

RSS - Posts

Water run off needs to be taken into account too. Too close to the gutter and the gutter won’t catch the water.

Indeed. I should have mentioned it four times.

Sorry, Ron. I must profusely apologise as I only counted three times and I wished to reiterate as I have seen this issue on multiple occasions via multiple media conveyances and I have seen for myself at various sites. But thanks for trying to belittle my comment, as I had subscribed to your blog and have enjoyed your insight on multiple occasions.

Just taking the piss, Dave.

No probs Ron, so was I.

where can i find a diagram of Australia`s wind zones

Hi Bob

This article has a wind map in it:

https://www.solarquotes.com.au/blog/solar-panel-clamping-zones/

The most important exclusion zone is to exclude Modern Solar from your installation. I had these guys install a 3 kW system on my roof and, had it not been for another contractor going onto the roof and warning me, I would have had what amounted to a suicide machine built onto the top of my house. They left a variety of materials on the roof including aluminium battens and they didn’t secure the panels properly. The electrical connections where left bare so that I would have had a 900 volt zincalum roof.

For maximising use of available roof space it may be time to consider solar tiles.

Has mention been made anywhere, which warns against installing panels too close together?

Enough allowance (say a 1 to 2 centimetre gap) needs to be made between the edges of each panel as a buffer to allow for heat expansion, otherwise, if butted together, the glass component of the panels may crack under pressure as the metal in the panels, expands.

Many thanks for the timely article, Ron. I’ve had plans in with the council for nearly three months now, so hope for planning approval soon, so I can proceed to the building approval holdups with a building surveyor. On the basis of some googling last year, and a generous dollop of caution, I’d allowed 1m at the ridge, 0.5m at the spouting, and 0.6m at the gable ends. That’s on single storey in an A1 wind area, with Sunlock SLRC700 clamps gripping onto Klip Lok 700HS from Lysaght. (There are then no roof penetrations.)

The 28 panels that allows on the 30 degree northern skillion will probably do.

If I put up more, then I’ll have to spend yet another fortune on batteries, or take up bitcoin mining, as it’s off-grid. (I’m seriously thinking of a Redflow ZnBr flow battery which can safely be hammered into the ground in an overcast period, plus a 10 kWh LiFePO4 bank for a DC coupled battery inverter which can then be fed 4 kW or so for high-load periods. (The Redflow is not allowed to be charged at more than 2.4 kW or so, so can not easily be thrown into a high capacity DC coupled system, I figure.)

If I can lay my hands on some 1 or 2 kW DC motors and controllers, it would be tempting to put the LiFePO4 battery bank in an on-farm electric vehicle for mowing, firewood carting, and boring the occasional posthole on the 7 km boundary fence, (Third motor with high gearing for the postholes.)

Why do more panels require more batteries? In general the opposite is true. Also i’m interested in your on-farm EV. Got a link?

When off-grid, power is either consumed, stored, or lost. I’ll have trouble enough consuming 7 kW most times, so adding more generation needs more loads or more batteries to be of any use. ( Otherwise I could as well use colourbond for the shade they provide.) As mentioned, the Redflow will only take about 2.4 kW, and LiFePO4 will take about 0.2C, i.e. 20A per 100 AH capacity. Once that limit is reached, excess generation is lost, even in the short term. By the end of a sunny day, generation will find no use as it is.

OK, in deep winter, generation will only be about 1/3 of nominal, so I’ve already overdimensioned the array. But enough? I’ll take another look now that there’s more room.

Sadly, I too am looking for a link for an on-farm EV. The reason for scouting for 1 or 2 kW DC motors and controllers is that I figure I’ll have to build one.

OK, I can design and build a 48v (brushed) DC motor controller (BLDC is harder), but in between battling planning/building approval bottlenecks, I’m already designing some DC electronics for the new build, with a couple of PCB layouts done, and some firmware just started. (At least I’ll let a builder do this house. I’ve left it too late for another full OB build.

What I need is 25/8 uptime.

Two storey – don’t forget access for gutter cleaning

Hi lots of worry re close to ridge how does that compare to tilt frames 40 deg on flater roofs

Hi Richard

As with panels mounted flush on a roof it will all depend on the manufacturer’s guidelines. Some roof mounted tilt frames have no specified exclusion zones while others don’t. If you follow the link in the article to the SunLock installation manual, or follow it here:

http://sunlock.com.au/pdf/SunLock%20Installation%20Manual_v4.5.pdf

You can see in the diagrams at the end that while they have a 20cm exclusion zone around all roof edges for panels mounted flat on a roof, for panels with tilted frames they have no exclusion zone but divide the roof up into a large internal zone, an intermediate zone, and an edge zone. Panels can be mounted anywhere in these zones, but more attachments are required in the intermediate zone and a lot more are needed in the edge zone, so it’s easier to avoid installing in those zones when possible.

Hi Guys, is it correct that all panels should face same direction ? Reason I ask is I’m about to have 21klw installed on my shop but it means one side will be one pitch and other side will be absolutely different

Hi Mick

Most solar inverters can two Multiple Power Point Trackers or MPPTs. This means they can accept two independent arrays of panels and so it’s no problem for your shop to have two sets of panels facing different directions.

I was having some issues with how my panels were installed in relation to water runoff missing my gutters. Whilst I couldn’t see anything in the standards that specifically relate to water, The Clean Energy Council put me onto the following information from AS1170.2 regarding wind design.

The following are excerpts from the AS1170.2

AS AS1170.2 APPENDIX D – SECTION D6 – SUBSECTION C

Minimum gap between 50-300mm underside of the panel and the roof

AS1170.2 APPENDIX D – SECTION D6 – SUBSECTION D

Panels with a minimum distance between the panel and roof edge of 2S where ‘S’ is the gap between the underside of the panel and the roof surface.

So if you have a 50mm high gap between panel and roof = 100mm minimum distance panel from the roof edge. 60mm gap = 120mm from roof edge, 70mm gap = 140 mm from roof edge etc)

I am sure that in high rain events that water will still miss my gutter, but this is a start

Hope this helps.

Just came across this article.

Interesting reading about the exclusion zones and mourning systems.

My question includes optimal gaps between panels on the same track.

As well as merit in installing horizontally as opposed to vertically, or even a combination of the 2 for max panel fitment.

My north facing 22.5° pitch Hip roof, a basic quote shows I could fit 18x panels but I’m trying to work out if there is another config horizontal or combo that will allow me to squeeze in more.

Any tips on how to calculate this?

Hi GLO

Panels only need a couple of centimeters between them. If you want a really low tech solution you can get the area of the roof you intend to use (the full area of the roof which is greater than the ground area it covers) and draw it to scale on a piece of paper with to scale paper rectangles to represent solar panels. Or if you are any good at image manipulation you could take a photo of your roof from google maps and use that.

Note you only lose around 14% of output by facing panels east or west and even south facing ones may only lose 25% — depending on location. So perhaps you could have say 4 kilowatts of panels facing north and 2.5 facing east or west. (This is assuming you have single phase power. If you have three phase power or otherwise can install more than 6.6 kilowatts of panels feel free to install as much as you can.)

Please Help. Can anyone suggest an engineering company that will provide a legal variation to AS AS1170.2 APPENDIX D – SECTION D6 – SUBSECTION C.

The installers have mounted up to the ridge line and they have not left the specified gap. The article says above “… certificate has to be obtained from a structural engineer that states the specific changes being made won’t reduce the strength or safety of the installation.”

Who will do that for us?

Olaf,

What brand of racking has been used?

Finn

Hi Finn

Just wondering if there is any way I could get 2 stacked horizontal rows of panels on my 3.4m vertical width roof space (2 panels stacked on top of each other would be 3.34m. Installers use Radiant Solar and I can’t find an exclusion zone on their website. I am guessing the answer will be no (from them and you)?. I guess the other alternative is mounting multiple landscape stacks but this would add a lot of framing and I imagine add quite a bit to the cost (I would estimate the roof length as 12m). Thanks

Regards

J

Josh, in addition to the manufacturer specifications, the other rule that applies is AS1170.2 as mentioned above. AS1170.2 sets an exclusion zone that you have to implement regardless of what your manufacturer says or does not so. Unless you are able to secure custom engineering documents for your roof structure which include the wind-loading from the panels. I was unable to find a company to provide custom engineering for my old roof structure but new roof structures can be engineered from the start to include panels without an exclusion zone. If not AS1170.2 must be observed and implemented.

Hi Ron

Wondering if you can help me, I have read your reports here and it has helped, im trying to find what the wind speed restrictions are here in South east Qld. My main concern is when should the installers not install panels on the roof. At what knots to they call it quits, I have been looking thru the QLD workplace & safety, typed in wind speed, wind restrictions. Can anyone help me here,

I’m afraid I don’t know what the restrictions are, but a competent QLD solar installer should know. Roofers should know as well.

The wind speeds are classified as zones in the standard. AS1170

Hi is it OK to have a corner of the panel (side of the panel ; Say 150mm 200sq mm ) flush with the ridge line (Not hanging over) running down the side of the roof ?

If I lowered the panels 200mm it would be clear but cant drop the panels any lower as I need to maintain the 200mm exclusion zone for the gutter

I am only having issues with the corners, all other areas are more than 200mm .(Its a tight fit)

I am looking at using Clenery rails (House is single stoty located in Sydney NSW

Thanks

Thanks

Dennis

Hi Dennis

Some solar racking manufacturers limit the area of the roof that can be installed on, but after having a quick look at a Clenergy installation manual it doesn’t appear to restrict placement this way:

http://www.clenergy.com.au/getmedia/a85945de-6966-4e92-8154-610abba6cb39/Installation-Guide_PV-ezRack_SolarRoof_AU_V2-4.pdf.aspx

Because of this, provided no panel is overhanging any part of the roof, what you want to do could be acceptable, but your installer will have to confirm this.

Hi,

I’ve just had a system installed and the panels do go over the corner ridge (by about 150mm) and all panels in rows and columns are butted up against each other with no gaps. Sounds like I should be concerned, I’ve asked the installers to comment on my observation. We’ve got Phono panels on Clenergy racking.

Thanks,

Rogan

Hi Rogan

For Clenergy racking there must be a space between the panels and the edge of the roof equal to at least twice the distance between the roof and the bottom the panels. I took this information from page 20 of their installation manual.

So no overhangs are permitted. As solar installers must follow the racking manufacturer’s recommendations I’m afraid your installation isn’t up to Australian standards. As installations must meet Australian standards you can insist they rectify it.

Ronald,

Thanks, the installing sub – contractor has replied stating that the ridge comment only applies to maintenance. However I thought that wind loading and the effect on the structure of the house was an issue too. I’d appreciate your thoughts on this.

“due to the complex of the install we picked the lesser of 2x evils and raised the panels to keep away from the gutter (waterfall would occur during heavy down poor)

The CEC *guidelines* states that the panel height off the roof should be the same away from gutters and ridge capping for servicing.

We left it this way as it poses no risk because maintenance on your roof is highly unlikely.

In regards to panel warranty, this should not void anything as all the clamps zones etc are within manufacturers specifications “

Hi Ronald,

Thanks for this informative blog. I got a quote that uses Mibet racking system. I can’t seem to find much reviews about it.

Have you heard of Mibet and how does it compare with the other racking systems you have mentioned above?

Best Regards,

Rom

Hi Ronald,

Happened to come across your blog and am slightly concerned.

Firstly let me say that I have been doing structural design in association with commercial scale rooftop solar installations (100 kW to 2.8 MW) for around 8 years for several major companies.

Each mounting system manufacturer has their own requirements/restrictions which are based on the testing to which they have subjected their products and the structural advice that they receive.

Many people have mis-interpreted the Australian Standard AS 1170.2 with respect to the local wind effects that occur at the edge of roofs and have adopted a conservative approach by defining these as exclusion zones. These local effects zones have higher wind suction pressures than the interior region of the roof but there is nothing stopping panels being installed on a properly designed mounting system.

I have designed mounting systems for installations across Australia including Wind Regions C and D.

For domestic installation the requirements of AS1170.2:2021 Section B6 should be followed. The distance between a pv-panel and a roof edge must be not less than 2 x the gap between the underside of the panel and the plane of the roof.

Kind regards,

Simon

Hi I have a question:

Scenario: 2nd storey, new Kliplok, flat roof approx 2 degrees; have been quoted 2 banks(?) of 9 x 440 w panels, and the installer reckons 30 mm on the side edge of the roof is ‘ample’ space (‘ exclusion zone” ?). My roof is approx 10.8m wide, and I looked up the panel size at 1.134 m width.

Q1: how close are the panels spaced together, do they have to allow for expansion? If the panels were spaced at 2mm distance I’d have approx 288 mm space left on each edge. Is that enough?

Q2:They are using MIBET Racking system. Is this ok?

PS I got the quote via solarquotes 😉

I think that most solar panels are stronger than what we give them credit for. I mounted a 100 watt panel onto some self made roof bars on my fourby (they were actually aluminium door tracks) , leaving a 15 mm gap between the panel and fourby roof. 4 6mm bolts through the panel frame did the job, never had a problem with it, and around 130 km/h reached several times when there was no-one else on the ( ahem, private) road. Has anyone actually seen solar panels come adrift in a reasonable big wind?

Hello, just wondering if anyone could comment please on a possible issue I have? We have a PV system on our roof. Recently, we had a new “flyover” patio. The patio installer has butted the patio right up against the panels. Is this a problem – i.e. is there a clearance requirement for and around solar panels? Thanks, David.

Hi David,

Can you send a picture to [email protected] and we’ll have a look.

When did anyone last see a solar panel fly off a roof during high winds…..I’ve never seen one myself. I put a 100 watt solar panel on my four wheel drives roof bars a while ago, and attached it with 3 6mm bolts on each end. While in the N.T where there was no speed limit I wound the beast out to a top speed of 175 km/h with no panel lifting/movement problems at all. There was a 15 mm gap between the panel and the fourby roof for cooling purposes, and the roof bars where made out of aluminium angle 20 mm in size. My point is that anything more than 100 mills from the edge of the roof to the panels edge is going to survive in most circumstances I.M.H.O.

Domestic installations need to be in accordance with AS1170.2 : 2021 Appendix B.6.1 where the minimum edge distance is twice the gap beneath the panel.

Darwin is in Wind Region C and the design wind gust speed is 250 km/h.

Hi Simon, thanks for pointing that out. I’m trying to confirm your interpretation of AS 1170.2 : 2021 because gses wrote a lot and as far as I can tell they concluded there was some ridiculously large minimum edge distance.

https://www.gses.com.au/new-version-of-the-wind-actions-standard-as-nzs-1170-2/

Are you able to post a copy of appendix B.6.1 under copyright fair use rules ? alternatively what are your thoughts on the gses analysis ?

Peter

Hi Peter,

B.6.1 was never intended to be used for large format buildings such as warehouses, it was written as guidance for domestic installations.

There is/was a draft update to AS1170.2 out for public comment and one of the changes proposed was to apply upper size limits for the application of B.6.1.

Hopefully I will be catching up with Dr John Holmes (Chair of the AS 1170.2 Committee) at the end of the month so I will see where this is all going and what is in the pipeline.

Thanks Simon. Figure 2 on the gses page above shows a 1170.2:2021 roof zoning calculation example for a residential installation with typical dimensions and gives an edge zone distance “a” of 1m which is huge ! How did you arrive at “the minimum edge distance is twice the gap beneath the panel.” ? is that a quote straight from B.6.1 ?

Peter

Peter,

There is a perimeter roof zone of width equal to the lesser of 0.2B,0.2D or H which is defined as a local effects zone. Within this zone there factors, Local net pressure factor (Kl) which are applied to the standard aerodynamic shape coefficients as determined in section 5.

With regard to Appendix B.6 which relates to Solar panels, it is necessary to read this in conjunction with B.1.3, Local net pressure factor, which states:

“For the design of cladding elements, and elements that offer immediate support to the cladding in free roofs and canopies, the values of local net pressure factor (Kl) given in Table B.1 shall be used. For other elements in free roofs and canopies and for all other cases in this Appendix, Kl=1.0.”

That is, the local net pressure factors do not apply to B.6 Solar panels.

With regard to minimum edge distance, B.6.1 states:

“The use of this Clause (B.6) shall be limited to the calculation of wind loads on solar panels with the following restrictions:

(d) Panels with a minimum distance between the panel and the roof edge of 2*s where s is the gap between the underside of the panel and the roof surface”

GSES may wish to revisit their guidance.

Thanks again Simon ! Your help is much appreciated.

Peter

This article is exactly what homeowners need before rushing into maxing out every inch of roof space for solar panels. The breakdown of exclusion zones by mounting system brand is incredibly helpful—especially the comparison between SunLock’s practical 20cm margin and Grace’s massive (and likely outdated) 2-meter buffer.

As someone exploring a new installation, I really appreciate the advice to confirm manufacturer guidelines and have upfront discussions with the installer. The point about water overshooting the gutter when panels are too close to the edge is one I hadn’t considered, but it makes perfect sense.

Thanks for the great content, Ronald. I’ll definitely be referencing this when finalizing my system design!