Solar panel technology has made incredible strides in recent years, significantly boosting rooftop energy production. Solar panel manufacturers have achieved this mostly by optimising their panels to push out more current than ever before.

But this progress has given rise to a challenging situation: the world of solar inverters is struggling to keep pace. Finding inverters capable of effectively managing the increased current output of modern solar panel arrays has become increasingly difficult.

Read on, and I’ll explain the challenges posed by high DC string currents and discuss the urgency for inverter manufacturers to catch up on current specifications or push back on panel makers to turn their ever-increasing wattage into more voltage.

This post is technical. If you are reading this as a lay person – you may want to skim the more technical stuff and just get a feel for how much can go wrong in solar system design and why a good installer matters – especially with modern, high-power solar panels.

The Challenge of High DC String Currents

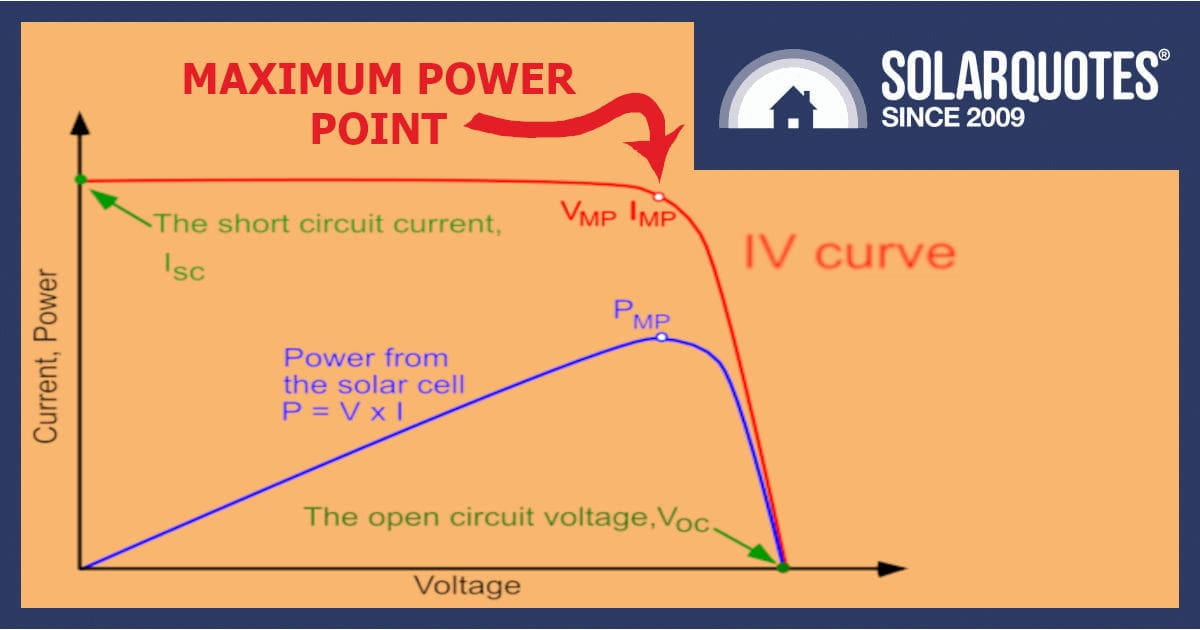

Making solar inverters handle higher currents is difficult and expensive because heat increases with the square of the current: P=I²R.

Fronius inverters, with their active temperature control fan, blow off heat, run cooler, yield more power, and have a higher current-handling capacity. In contrast, a random competitor like SoFar addresses heat issues by incorporating a large alloy heat sink and attaching a warning sticker about the unit being hot to the touch!

Here you can see the Fronius is running cooler than the passive inverter next to it because the heat is streaming out of the top, actively driven off by a fan.

So, while I think it would be helpful for panel makers to revert to higher voltage, lower current solar panels, at the end of the day, it’s the solar inverter manufacturers who are going to have to catch up if we’re to avoid problems with panels that are currently on the table.

Many Inverters Now Can’t Handle A Parallel Array

Many roof designs require two strings of solar panels connected in parallel. When you parallel two strings, you double the current from the solar panel array.

Right now, unless you specify a commercial-sized 3-phase inverter in the 15-30 kW range, few domestic inverters can effectively handle the current from parallel arrays.

This leaves designers hamstrung when they try to get big systems built using high-current panels. If you want a maximum-effort power system, you must buy two inverters.

As the solar industry progresses, inverter manufacturers must rise to the challenge.

Hurrah For Enphase IQ8

At least Enphase microinverters finally have a solution with the release of IQ8 series. Rated for 360 or 384VA they can handle 37% more current… and that directly equates to yield.

When you’re comparing 360VA IQ8ac at 14 amps, and 366VA IQ7a at 10.2 amps, the similar VA (wattage) ratings are shown up as a bit misleading and that has caught out some less than observant installers.

REC Panels Allow More Design Flexibility

As we outlined recently, REC has now released the latest iteration of the Alpha Pure range. The new RS variant is a whacking 470-watt panel (with an enormous 1205 mm width), but the best part is the voltage. REC has made their new model with 88 cells instead of 54, allowing for better shade tolerance and more voltage.

Solar panels like this tip the scale back into your favour because if we take an average 6.6 kW system, the panels can be more flexibly deployed on a challenging roof or simply run at higher efficiency if the space allows a simple layout.

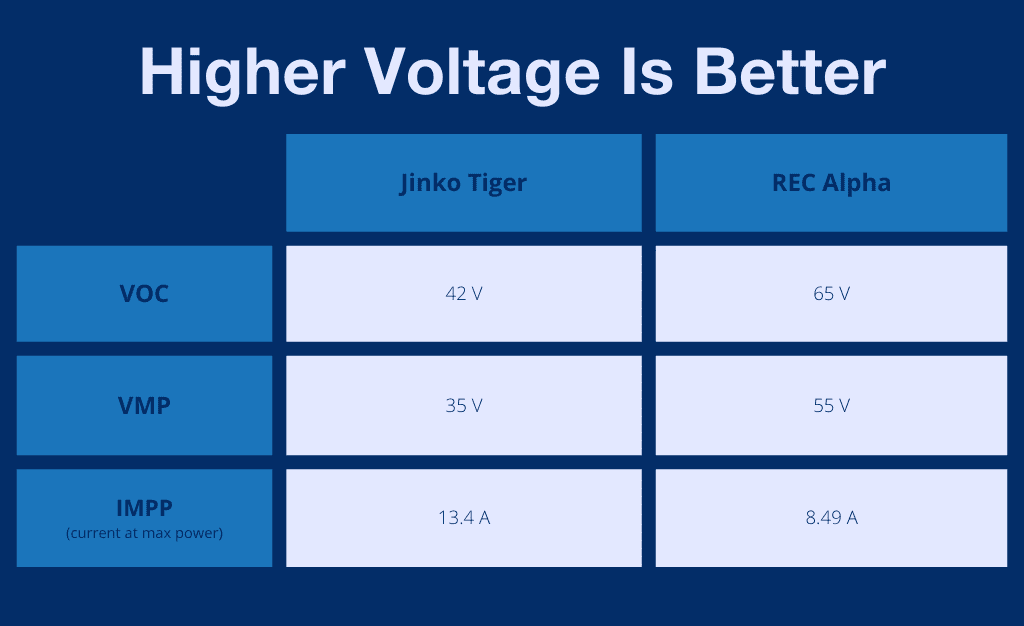

Take the high current/low voltage Jinko Tiger Neo JKM470N-60HL4 with the following specifications:

- 42 VOC = with de-rating applied and a 600 VDC ceiling, the maximum string length is 13 panels, not 14 for a whole 6.6 kW system.

- 35 VMP = working string voltage for seven panels is only 245 V at maximum power.

- 13.4 amps at maximum power means even if you could find enough voltage, parallel panels would clip badly on most inverters.

Even on an ideal roof, this low voltage might cost you a 2% yield for the entire system life. So, while you have the latest 22% efficient panels with less than ideal voltage, you might as well have some 3-year-old 350 W units with the right characteristics.

Whereas the REC Alpha Pure-RX 470 W panel has a high voltage/low current specification:

- 65 VOC with de-rating would allow for 8-panel strings.

- 55 VMP means the string voltage for six remaining panels in a 6.6 kW array is still a healthy 387 V

- 8.49 amps at maximum power simply means less waste heat.

Even on a complex roof, a string of 4 can provide a passable 221 V, while paralleling two strings of 5 at less than 20 amps can result in 227 V. All of a sudden, it’s feasible to make a much more painful roof work for you despite dealing with increments of panel size that are nearly half a kilowatt each.

Higher solar panel voltage means a lower current for these 470 W panels.

Australian Standards Madness

Commercial installations are allowed to operate at up to 1000 VDC, and with yet another quirk of unharmonised Australian Standards, so too can a domestic system, but only if it’s not grid-connected.

We’ve covered it before in other posts, but silly Australian regulations have been addressed somewhat by some forward-thinking solar panel maker Winaico. Increasing the number of strings in parallel becomes a potential solution for larger systems, because they can be built with fewer things to go wrong.

Winaico’s answer is to embrace high current and an even higher 30 amp fuse rating for their panels. However, this begs the question: Why would a current-limited source like a PV panel, which only delivers 13.8 amps under short circuit conditions, require such a high fuse rating?

Understanding Fault Protection

The answer lies in the design of DC string configurations. Bear with me for some electrical abstraction.

With panels connected in parallel, it is vital to account for potential faults. If one string becomes short-circuited, it must be able to handle the energy flow from all the adjacent strings being funnelled into the fault. Herein lies the complexity. According to regulations, when there are more than two parallel strings, additional protective measures are required to prevent overwhelming the system.

Suppose a system consists of three parallel strings, and one develops a fault. In that case, the remaining two strings can supply a combined current of 26.32 amps, exceeding conventional panels’ standard 20-amp fuse rating.

To mitigate the risk of fire, installing fuses on every string is obligatory, which increases components, labour, and overall complexity. This, in turn, raises the chance of failures as fuses degrade over time due to thermal cycling. Consequently, compromised fuses may blow unexpectedly, resulting in lost energy yield and additional service calls.

The Invisible Problem

Parallel strings blowing fuses can go unnoticed, and the warning bells don’t ring loudly. Solar Analytics might pick it up for you. A savvy customer interested in the monitoring may also have a seat-of-the-pants suspicion.

Still, it could take years before anyone realises the lack of energy production from the system. They’re also difficult to diagnose, for example, in old SolarShop jobs, which feature hidden fuses secured under panels with specialised 5-pointed screws.

It’s an insidious problem. I have seen firsthand where energy bills continue to accrue because the system owners don’t realise half the $35,000 – 10 kW system isn’t working, but the green light is winking on the inverter, so nobody is aware. That instance was the first time I sold third-party monitoring for solar after they’d lost months and months of yield.

So What Is the Upshot?

When qualified electricians need to spend a couple of grand and a weeks training to get an actual solar design endorsement, there are a lot of industry veterans who rail against the notion that unqualified salespeople can design and specify solar without really understanding what they’re doing.

The vast bulk of solar power systems are configured by a computer program, which largely takes human error out of the equation. Sometimes compromises have to be made to make things fit; other times, there just isn’t enough space, but from my perspective, it’s even worse to see the occasional solar industry professional, those with experience who should know better, make fundamental errors in panel and inverter compatibility.

Seeing this “bill buster” from another job, we could tell from 30 metres away that the string of three tacked on the end wasn’t compatible.

I’ve had end users who can find and use online configuration tools to prove they’ve been sold a pup, and those are awkward conversations to have with an installer when you ask how these errors were made. In many cases, I think it’s just an oversight brought on by the timely stock availability at the right price.

Sometimes it’s just laziness. The best advice I can offer is to drill your installer. Don’t treat them like idiots, but show you’re interested, and if they’re truly across the brief, they can explain the details.

And finally, beware of the sales company that sells you one thing and substitutes it for another on the install day; it’s a sure sign they’re shonks.

RSS - Posts

RSS - Posts

Thanks Anthony, I think I am in the situation you describe, with IQ7a microinverters paired with high current, low voltage 54 cell panels. They are 415 watt panels but I’m lucky to see 300W out of them on perfect, cool mid day sun on a north facing roof in Sydney. I haven’t broached the subject with the installer yet.

Hi Anthony,

Interesting article which really does explain a lot of the limitations with string systems.

With SolarEdge systems however the DC String voltage is fixed by the inverter, the current is then managed to drive the power output. So, in effect an MPPT per module (on a resi system anyway, one per 2 modules on a commercial system). Another way to look at is the array output is driven by the inverter which is controlling the output of the optimisers, in string systems the inverter is responding to whatever the modules are pushing towards it.

What this topology means is that as long as there is headroom in the optimiser, so putting an S440 on a 425W module for instance, the SolarEdge system can capture all of the power that the module can generate. Often this is actually higher than the STC value of the module as in Australia we have conditions which exceed the nominal test parameters that give modules their plate rating, especially if a SolarEdge battery is also part of the system as its true DC coupled allowing the array to produce the maximum charge rate of the battery plus the maximum output rate of the inverter, this can be up to 300% of residential inverter Ac rating.

I also agree that having PV modules with higher voltages also helps with efficiencies, again this is why our optimisers are designed to capture all current modules, our optimisers start with an input voltage of 60V with a current rating up to 14.5A (15A on the S500) and the S500B goes up to a whopping 125Vdc input.

Parallel arrays, or even arrays made up of three or more strings are also not an issue given SolarEdge’s control over the entire DC bus, the only thing installers need to make sure of is adhering to the minimum number of optimisers per string.

Ultimately, system design is simpler with SolarEdge, systems are more efficient, more productive and we can cater for all modules currently available in Australia.

Hi Anthony

Great article as usual. This has been a problem I have come across when looking into adding more solar to my home or for friends and family. I have found that most “installers” are just looking to sell and don’t understand the product they are selling.

I agree with James above in that optimisers will certainly solve the issue. Personally I love optimisers just like I love batteries. Its just that they are harder to justify in terms of ROI unless some new subsidy appears.

When I crunched the numbers in terms of adding optimisers it would take 57 years to pay them off so it looks like I am better off carefully choosing the right inverter/panel/layout combination that optimises production to cost (LCOE). I would say the same applies to micro inverters in that they are one of the least efficient ways of converting DC to AC in terms of wasted resources in duplication of electronics however I agree that Enphase make beautiful examples of these.

Something I have noticed is that a good string inverter with strings that are a reasonable length tend to be able to produce more usable power under rain/storm type conditions than microinverters. This may be due to the narrow operating range of each micro inverter whilst for a (high quality) string inverter it tends to have a wider operating range. The small amount generated by each panel adds up to something the string inverter can still harness and make power from whilst the micro inverterters are basically off as the can only operate as individual units.

I will also say a lot of this boils down to the same argument as the inverter oversizing rule. Fin points out that as the panels are subsidised your better off with the oversized array. That same argument can be applied to the clipping if the overall cost is still the best value in terms of how much you will save on power vs how much it costs. That does not mean that we should just accept it however we need to look at the least worst option.

…as a definite layman a lot of this is over my head, so I skipped parts of it like you said but 1 part of it caught my interest…we recently had a 13kw jinko panel system installed (pretty sure they are the JKM470N-60HL4 as used in your example above at 22% efficiency) with a 10kw Sungrow inverter …it seems to be running very well …but atm it’s a bit hard to tell if the system can output to its full potential (ie that it can do 10kw on a clear sunny day) until SAPN change us to the flexible export limit to 10kw but on the next sunny morning, I guess I could load her up with a 5kw load on our house, while she exports 5kw, to make sure all is running well??? 🤔…my guess is it’ll be fine, so in your example above using jinko panels, did you mean if they’re connected to an inverter that’s sub-par ?

Hi Hamish,

You’ve got it about right yes.

Pick the best part of a cool but bright day if you can get one. Sunshine produces direct radiant heat that will curtail your output, a fact the people offering panel cleaning use to make themselves look good. They hose panels down and make them cool, which improves output momentarily.

Anyway choose the best conditions, load up more than 5kW on the house. Maybe get an idea by turning the stove, kettle and toaster on during the night to know what will provide enough load, and what the increments are as you turn them on.

The inverter should try to meet that load you apply in the house first and then keep exporting as much as it can.

The examples don’t target Jinko as inferior, it’s just a common panel, with a high current output, which you have to keep in mind when designing the system. Sub par is what you get when the inverter overwhelms a badly matched inverter.

It may be easier to adapt a couple of strings of three REC Pure 470W on a system with battery. I’ve sketched in three of ’em on a west facing roof, feeding a Victron 250/100 MPPT, as that seems the best way to utilise the 9 panels which fit there. (It handles 70A of PV) There’ll be a Victron 450/100 with two MPPTs for north, and a couple of PV inverters to round up another big array. Either 65 or 68 panels, if we can fit them. (Save the Planet – Fill the Roof!)

With two PV inverters, and three Victron Multiplus IIs (cheaper than a pair of Quattros, I figure), I don’t foresee much trouble rounding up the PV output on the grey days for which it is dimensioned. Off-grid, I’m stuck with heating water after the 46 kWh battery bank is charged, and running the aircon flat out on hot sunny days. (Baking scones? How many can you eat?)

In Gippsland, this week has seen three heavily overcast days in a row, but then hours of sun today. If not still in shipping cartons, the battery bank would have held up the half week, and it is the need to throttle charging to under 15 kW for battery longevity, that would have delayed Battery Full till lunch time. I’m looking forward to seeing Victron’s DVCC mode manage battery charge rate independently of free energy flow to variable AC loads via the inverters.

Hi Erik!

May I ask who designed your system? Sounds like they know whats going on 🙂

Flattery will get you a looong way. The mixed AC & DC coupled system is an enlarged version of a professionally designed system my brother has been running for a couple of years now. My ancient Dip. Elec. Eng. is by now mostly a source of excess confidence, and it’s several years of recent study of datasheets of likely system components, and a bunch of on-line seminars and lectures, which guide variations on a known system. I had initially favoured Selectronic, but found energy management and system configurability inadequate to my needs, or at least undocumented. Just look at Youtube to see how configurable Victron’s system is.

I can’t afford my brother’s Zenaji LTO batteries, so am trying 48 EVE 304 AH LiFePO₄ cells with JK BMSs and Heltec balancers. Much less cycle life, but much cheaper. Off-grid, my 46 kWh is more practical than his 15 kWh.

While AC coupling will drive immediate loads a smidge more efficiently than MPPTs and inverters, the latter are better for battery charging, so a mix can work well, so long as the battery inverters can throttle the PV inverters when needed. I wanted to be able to float DC power across the battery terminals to varying loads via the inverters, something that fixed limits on the MPPTs can’t do. Victron’s DVCC mode is the only method I’ve seen, both on paper and in action, so I’ll see how well it works for me. Managing a smart EVSE to only use excess solar power is for later.

I designed and owner-built the 25m long garage/workshop/dwelling, am building the LiFePO₄ triple battery bank, and have installed VenusOS on a RPi4, preparatory to fiddling with Victron’s open source control software, if necessary to achieve objectives. (30 years developing embedded software gives courage, but 70 trips around the sun dims the energy a bit.)

A bloke has to keep himself occupied in retirement. A technical project is a shot in the veins for an old project engineer. (Aim to have fun, I figure. There’s no refund on the ticket.)

Hi Anthony

please excuse my ignorance as a lay person, but can you please elaborate on that last picture where the caption says that string of three panels isn’t compatible?

Hi Mark,

With 3 average panels at 30ish volts maximum power point you’d only have 114volts for a 3 panel string. While inverters are getting more flexible, they’re not often efficient at 100v like they are at 400v. Basically that system can’t be well balanced having so many panels on one MPPT and so few on the other.

Some installers will fit “optimisers” such as those made by Tigo, which will help with performance of these 3 panels as part of a longer string facing another direction, but it’s not ideal and isn’t common for cheap systems either.

AS/NZS 4777.1:2024 has been published yesterday and now allows 1000 VDC in domestic installations!