Welcome back to our monthly chat. I’m Pat from Southwell Solar Inspections. In my line of work, I get to chat with system owners after the solar installation team has packed up and moved on. It’s a unique chance to hear how the system is running once the initial excitement has faded.

I’ve found four critical things to get right on the day that are key to a happy customer.

Installers should read this because – if forgotten – you can expect an upset customer and the chance of the dreaded one-star review. But if these things are sorted on the day, you’ll likely have a customer beaming with pride, five stars on the web, and a lower customer support burden over time.

Homeowners gearing up for a solar installation should stick around, too. If you proactively ensure these are addressed before the installer team packs up and leaves, it will make any inspector’s life easier and your solar ownership experience happier.

#1 Check Your Monitoring

Think of monitoring your solar system as your home’s energy dashboard. It’s essential and usually, you’ve paid for this feature in your system’s price tag, including the setup. Just like you wouldn’t ignore your car’s dashboard, you shouldn’t overlook your solar monitoring.

What Goes Wrong

Sometimes, after a busy day on the roof, installers might wrap up their work without properly commissioning the system, even finishing after dark, which means they can’t test the monitoring when the system is generating power. Or they might stumble with the Wi-Fi connection and pass the buck to the homeowner to sort it out with vague promises of follow-ups that never happen.

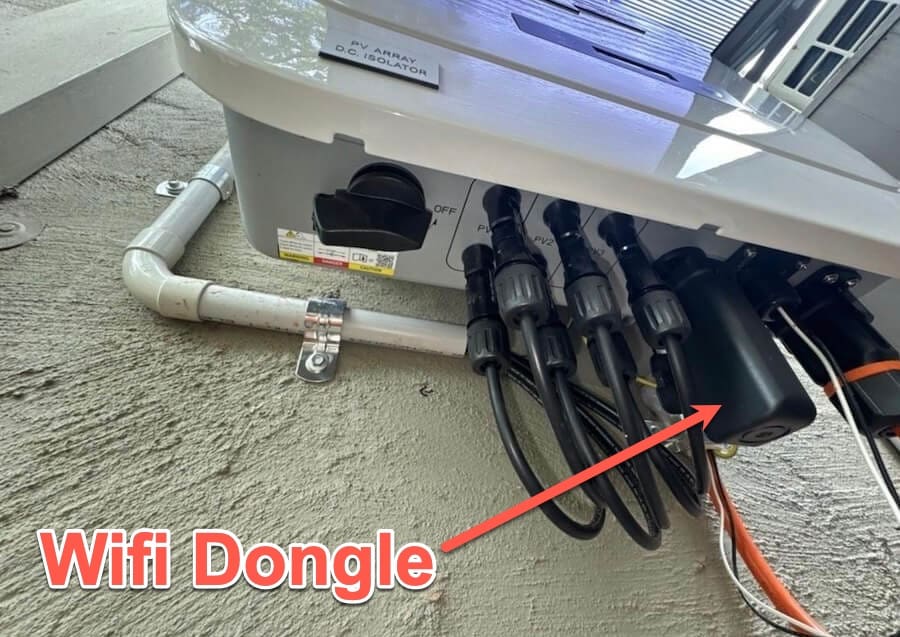

WiFi dongle connected to the inverter. However, this was never connected to the monitoring platform.

Fixing the Issue: The setup of monitoring should be a no-brainer for installers; it’s as much a part of the installation as the solar panels or home battery. Homeowners, remember that monitoring is your right, not a bonus. If it’s not working, remind your installer it’s part of what you paid for and insist on a fix. If they’ve commissioned the system in the dark and you’re left in the lurch, don’t be left wondering. Get on the phone with the installer or the retailer immediately. You deserve a fully functional system from day one.

#2 Missing Documentation

Why Docs Matter

Just like you wouldn’t drive off the lot without the owner’s manual and service records for a new car, the same goes for your solar system. The Australian installation standards AS/NZS 5033:2021 and AS/NZS 4777.1:2016 aren’t just guidelines—they’re the rules of the road, requiring that you receive thorough documentation. These papers are the key to understanding your system and claiming warranties. They might even be necessary for insurance claims down the track.

The Missing Pieces

Homeowners left without the critical documents post-installation is more common than it should be. Sometimes, it seems the installers didn’t bother or just forgot. But forgetting isn’t an excuse; providing a documentation package is a requirement.

How to Make Sure You Get Your Docs

For installers, it’s simple: follow the standards and keep a checklist. Make sure every homeowner gets a complete set of documents. For tech-savvy companies, providing a QR code in the main switchboard or meter panel for easy access to digital documents is the gold standard—aim for this.

Homeowners, be proactive. Ask for these documents from the start—either in print or via email. Ensure you have all the user manuals, warranty docs, and compliance certificates. It’s part of the deal, and you’re entitled to it. Don’t settle for less.

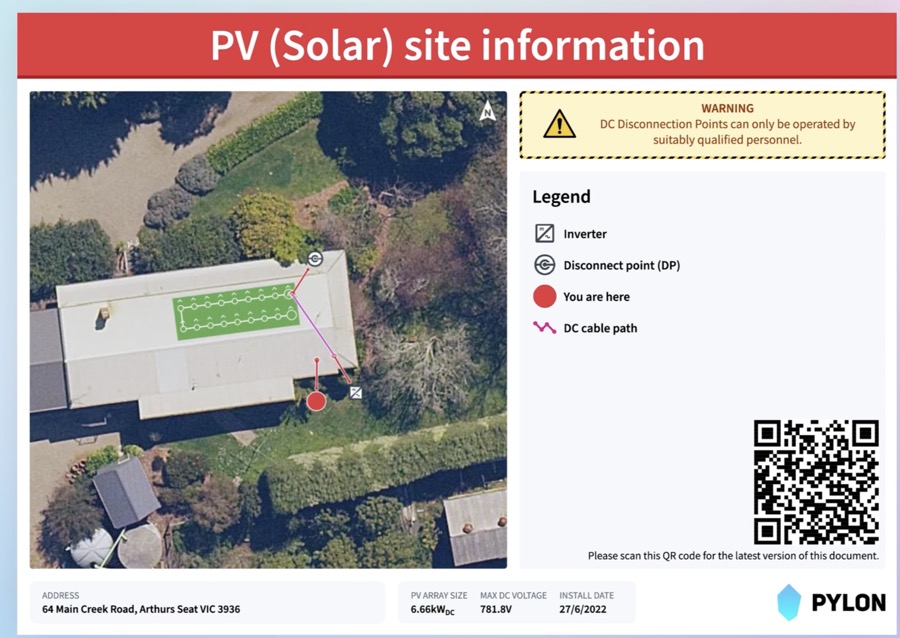

An example switchboard label. The QR code works – scan it to see the example documentation package (click on the house in the top left corner of the QR-linked site plan to see the links for the User manual, Component Documentation, Commissioning Report and Maintenance logs).

#3 Confirm Any Roof Damage

Why This is a Big Deal

Imagine this: your system is all set up, but the installer leaves behind a trail of minor roof injuries—a chipped tile here, a shift in the ridge pointing there, maybe even a sneaky crack repaired with silicon. Sure, these seem like small fries now, but untreated, they’re brewing storms for leaks in your sanctuary.

What’s Being Missed

Too often, these little damages don’t make the report. Installers might overlook a cracked corner or hastily cover a break with silicon, hoping it holds. But you, the homeowner, should be clued in. These aren’t secrets to be kept; they’re potential headaches to prevent.

A tile snapped in half horizontally and then silicone up by the installers. The homeowner was not advised.

How to Avoid and Fix Roof Issues

Installers, we understand that dented iron happens and broken tiles are sometimes impossible to avoid, but thorough checks after installation are a must. Spot a problem? Don’t just patch it up and hope for the best—inform the homeowner. Transparency is always best.

And homeowners, it’s your castle; protect it. Get in the habit of snapping photos of your roof before and after the installation—timestamped, for truth’s sake. These can be invaluable for future follow-ups. Because when it comes to your home, being in the know means staying on top—quite literally.

#4 Understand System Maintenance

Keeping Things Running Smoothly

Proper maintenance is key to ensuring your solar system stays efficient over the years. There’s a lot of guidance out there now, so even if it’s not initially provided, you’re not left without resources.

What Often Gets Forgotten

Unfortunately, some homeowners are left clueless about system maintenance because they’re not informed. And let’s set the record straight—solar systems are not ‘set and forget’ devices. Some installers incorrectly claim they require zero maintenance, or they suggest using harsh chemicals or high-pressure washers, which can damage your system.

Teaching the Basics

To all installers, part of your responsibility is to educate the homeowner on basic system care. This is easy and will greatly benefit the system’s long-term performance. Maintenance instructions should be included as part of the essential documentation package. And consider providing a straightforward guide for homeowners to refer to.

Conclusion and Call to Action

These four details can greatly impact how customers experience buying and owning their solar systems. It’s about completeness and care in the entire installation process. If I’ve missed something, I’d love for you to leave a comment below. It’s through sharing our experiences that we can all learn and improve. Let’s work together to improve solar and battery installations.

Thank you for reading and being part of the discussion!

RSS - Posts

RSS - Posts

Should you use a detergent when cleaning solar panels? I’ve heard people say you should and others say you shouldn’t. My uneducated view would be that a detergent should be used as micro scratches would be inevitable without any form of lubrication.

If detergents should be used can you recommend what to use?

Thanks

Hi John, this will help you gather all the information you need to know about cleaning Solar panels.

https://www.solarquotes.com.au/blog/how-to-clean-solar-panels/

Thank you Pat for a very informative article. It will assist me in following up on documentation that was not forwarded to me at the time of quote or after installation.

On another point, how is the inverter connected to the switchboard??

Is it wired with the battery directly to the main switch or, to the house circuit to provide power during a blackout??

My Solar system works great, but the Fronius inverter they installed generates a lot of EMI, Electromagnetic interference right across the radio frequency spectrum all the way up into the VHF, Very High Frequency part of the spectrum every 100kHz. Harmonics of the chopper, creating the pseudo 50Hz sine wave, no doubt. I have contacted Fronius several times. They keep referring me back to the Installer. The installer says he will pass it on to their non-existing support department, and so it goes on month after month. Where do I go from here? Maybe they don’t understand the problem?

Who is responsible for equipment compliance to Australian standards in regard to EMI? The ACMA?

Also interested about how to reduce high frequency transients and harmonics on electrical wiring during a solar inverter install. How are you measuring your EMI levels?

@Solar Quotes any advise what additionally can be done during an install to filter inverter outputs beyond the filters that are typically included internal to the inverter? For context, looking to get a Powerwall 3 and solar install when it hits Australian shores.

As a Ham Radio operator, I have transceivers which include spectrum displays for the various Ham radio bands between 1.8MHz and 1300MHz.

These EMI spikes show up as narrow vertical lines spaced every 100kHz.

I also have a portable spectrum analyser which covers frequencies all the way to 6Ghz.

The height of the spike shows the strength of these EMI products in dBm of power.

They are so strong, I can hear this EMI in my portable VHF radio as I approach my house.

The installers looked puzzled when they unpacked the Fronius Inverter and a big ferrite core, which was meant to have the AC Inverter output cables pass through the core many times to choke the high frequency components created by the switching MOSFETs creating the artificial 50Hz AC sine-wave.

FYI EMI, = Electro Magnetic Interference.

FYI MOSFET, = Metal Oxide Semiconductor Field Effect Transistor.

Interesting.

Fair to say this EMI would be carried and emitted across the electrical circuits in the home or mostly emitted locally as RF from the inverter itself?

Presume this EMI wouldn’t exist when inverter isn’t outputting ie at night?

Any devices that can be installed to further filter this in your experience?

Yes, the AC wiring inside the house acts like an antenna and radiates this noise into the house and into the wires in the street where they add to the noise created by all sorts of other cheap and nasty switched mode power-supplies, phone chargers, USB chargers, etc.

It’s a global problem made worse in countries that allow non-compliant devices into the country or installer who don’t install filters because they don’t understand the problem and how to fix it.

Switched mode power-supplies are very efficient but create EMI unless filtered properly.

Evidently from your experience installing a quality inverter provides inadequate filtering (or was it not installed correctly in your view)?

Not a lot on this topic online, here’s a video showing EMI on home wiring from a Powerwall (EMI does seem significant): https://youtu.be/fGYXcpYGbco?si=fvpQZMzRM-BWJtpp

Would appear an inverter creates more EMI than the typical offenders you mention in the home (switched mode power supplies etc).

Any leads on filters or companies to talk to about filtering inverter outputs further?

Pat, there’s even more for a savvy customer to be alert to. I’ve been across a couple of installations, and have seen:

– A 70 sq mm DC cable lug not quite tightened up on an inverter isolator. Stink from insulation revealed it only on heavy load. Replacement necessary.

– Parallel battery inverters not load sharing well. Input cables had 20 cm length difference (not great), but daisy chaining their output instead of individual circuits to the the main board had greater effect. Separation improved load share no end. Much more capable system now.

– EVSE not working in solar-surplus-only mode. Firmware upgrade & comms tweaking needed.

– Logging turning off at 8 p.m., resuming 8 a.m. (I wasn’t close enough to that one at the time, to catch exactly what fixed it.)

– A battery busbar which ran hot to the touch on high current. Needed to be ground flatter for greater contact area. (That was pre-commissioning work in progress, so really doesn’t count, but remains illustrative of what could be missed, perhaps.)

It would be nice if thermal cameras were cheaper.

Even after the inspector has signed off, there can be a lurking issue, either intermittent, slow developing, or firmware. Once there’s half a dozen boxes, all with blinking lights, it’s not a simple system any more. It can take a shake-down cruise to winkle out teething troubles. (It is damned hard to never have any.)

My EV went back for a 1000 km check-if-anything-fell-off inspection today, 800 km late, admittedly. If there are house batteries, as in all off-grid installations, there should probably be an installer’s interrogative revisit of solar installations 30 or 60 days after inspection. Or do we just assume the customer will/can keep an eye on it? (Seems like good CRM to me.)

No matter how much care is taken, even when a great quality company is contracted, unforeseen accidents do happen. When they do, the mark of a great company is how quickly they react to and fix the issue.

This happened to us after the solar was installed in 2021. LOTS of things going on in our home’s roof space, including ducted vacuum system. Whilst guys were rummaging around, running AC cables from the roof to the Enphase controller box in the garage, they inadvertently separated part of the PVC pipes, which run from the vacuum wall connectors, through the ceiling and down into the garage, where the motor and vacuum bag are located.

it wasn’t until a few days after solar install was completed that we required the ducted vacuum. No suction.

Call the installers and from memory, within a day, the boss was in our roof space, located and sealed up the pipes. No fuss, no bother and most apologetic.

Oh, and by the way, yes, I did go over all aspects of our solar install with the boss, who commissioned the microinverters and ensured the system was operating as it should as soon as the system was operational. Checked the CTs were clamped in the correct direction on all 3 phases. Switched on and off various high powered devices.

A perfect install and a great after sales/install response.

On the evening after our panels were installed, we found that there was no TV reception- the satellite dish had been partially masked by a panel. The installer (DMS Energy) turned up the following morning, which was Good Friday, and restored our TV reception. So, as David says, little mistakes are easy to make, but the mark of a good company is how well they respond.

My system was installed in a small New England Regional town and I was told not to turn the system on until Origin Energy had approved. He ran me through the system so I knew it worked.

The Installer (who I located through Solar Quotes) emailed me that evening to inform me that he had emailed the documents through to Origin. So Origin had 14 days (under legislation) to do their stuff and tick the box before I could turn the system on.

I didn’t wait, I turned it on after the Installer had disappeared out of town. It all worked like a charm. And I could read the details on my laptop.

I gave Origin the 14 days and still hadn’t heard from them. So on day 15 I rang them and was informed that the Installer hadn’t sent the papers in. I looked at his email to check it. Then rang him and told him. “Sigh, this happens all the time with Origin”.

So I rang them back and gave them times and dates, they were adamant that they didn’t have them and I had to go through …… I said I wont, I live in in Tenterfield and he works in Byron bay and isn’t going drive up here to tell you what he did, you have the documentation. They were adamant that we were at fault.

I then contacted the NSW Energy and Water Ombudsman and emailed them all the documents I had and emails. They sorted it out and got Origin back on their track. This all took 6 weeks, so the first Bill came in with the system reading on the day.

I got back to NSW E&W and they again talked to Origin and the Bill was re-written and backdated to when I switched it on.

There was a funny aside some months later. I headed off to Hobart for a couple of months. I switched off the Internet while I was away. Because I used it where I started in Hobart.

I showed my Partner how the App on the Laptop went but it stopped “recording” the deetails and I couldn’t work out why. It wasn’t until I got back home that I remembered the App ran on my Laptop. So no local Internet, no transmission of Solar Data. 😉

Two points.

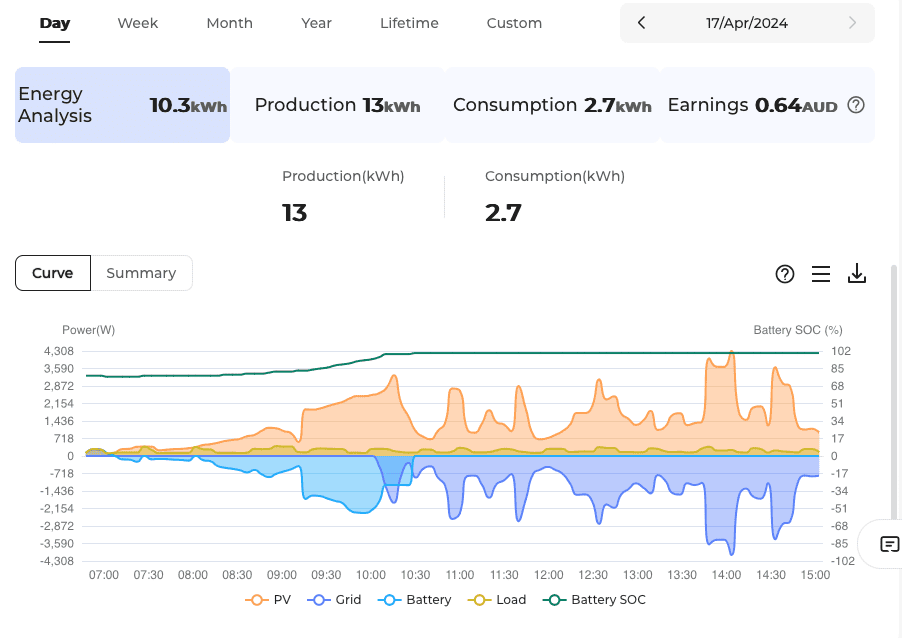

1. The image “monitoring-screenshot” – what inverter is that from?A comparison of the screenshots of the monitoring, from different brands and models of inverters, would be good for prospective buyers of inverters; one reason for the choice of my current inverter, was the sample monitoring display, when compared with that of other hybrid inverters.

2. An extremely important thing to check, before the installers leave the site, is that the site is cleared of rubbish. After an expensive (about $30k) installation, that involved replacing and upgrading an existing system, a day, or a couple of days (one of the two, I think) later, I was walking through the lawn grass, that was about a foot high, and, I started finding bits of metal, including the panel frame mounting brackets and bolts, left in the grass, to kill or maim people. So, I contacted the retailer/installer company, and required a site attendance, to examine the danger left. The company director came, and, examined the problem, and, as I asked him, what size hole do you think this piece of metal would make, when it would go through an adult or a child (children walk along the street outside or residence, on the way to and from the local primary school, a couple of hundred metres away), after being thrown by a lawnmower? As I told him, when I was a child, a school headmaster showed the children at the primary school, the damage to a brick wall at the schoolgrounds, where a cap gun had been thrown by a motorised lawnmower (and, told us not to leave toys or other things, in the grass. The director came back to the site, with a metal detector, and, found most of the metal components that had been left in the grass, over about ten square metres. There was no logical reason for the people to have carried the metal waste over the grass, which was next to a paved area. The site was recklessly left in a dangerous state, by the installers, requiring remedying by the company director. So, I was furious.

When the people on site during the installation, and, at the end of the installation, do not include the person who designed the system for which the contact was authorised, issues arise like panels not being placed where they were supposed to be placed, so decreasing the system efficiency.

My previous post ran out of available characters, otherwise, this would have been included, as the expensive job that was done, was highly unsatisfactory, causing me to believe and contend that every PV system installation or change, should require to be inspected and signed off by a regulatory inspector, with the inspection including site safety, before the job is officially regarded as concluded.

Safety should be paramount, and, every job should be properly done in the first instance, to not recklessly endanger the household or anyone else, and, every job should be properly done according to specifications.

And, it appears that the only way to ensure all of this, is statutory requirement for regulatory inspectors to fully inspect every installation and the parts of the site affected by the installation, and, signing off on it, to ensure compliance, before the job is officially declared concluded, and, before billing for the job, is initiated.

Hi Bret,

I appreciate your frustration. Victoria has compulsory inspections but having everything reviewed to the nth degree would come with a cost to the consumer. We really need to be careful about what we wish for in terms of regulation, and be responsible about who we employ to work on our houses.

I’d really encourage you to leave reviews for your installer.

https://www.solarquotes.com.au/installers/reviews/