Cable conduit can look awful on a solar roof, and is overused by crap installers. But sometimes a little bit of rooftop rigid conduit can be justified. Image: Crap Solar Facebook Group

Protective electrical conduit is a small part of every solar install, but using it properly can make or break both the compliance and the aesthetics of that job.

This post will explore the use of cable conduit in and on a solar roof.

Conduit In The Roof

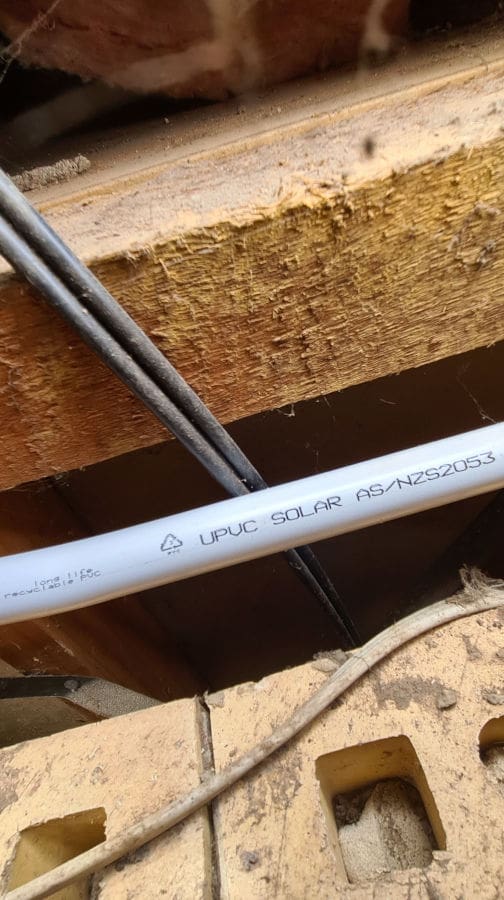

Since 2014, DC wiring for solar arrays has been singled out for special attention by Australia’s wiring standards. Once DC cables leave the array and enter the building, they must be encased in heavy-duty conduit, labelled “Solar DC” every two metres or where it changes direction.

The latest solar installation standard, AS5033:2021, has even more specific requirements for where cables can be routed and secured inside the ceiling space.

The DC solar wires must be in labelled conduit after they enter the building. The labels are red.

These rules are designed to protect people such as firefighters who poke sharp things like axes through the ceiling.

They also protect the wiring from damage by errant rodents, especially the ones who install pay TV.

Solar DC cable crossing path with black twin Fauxtel TV cable. These two would look identical if it weren’t for the Heavy Duty PVC conduit marked “SOLAR”

Despite specific labelling, confusing the black twin DC solar cable for satellite aerial cable could be equally exciting and lethal for those holding the side cutters.

So that’s solar in the roof – it’s explicit in the standards it must be in conduit, but what about on the roof?

Bad Cable Conduit On The Roof

I’ve seen terrible solar cable conduit work done on rooftops by tradespeople who, I assume, work for peanuts on systems no doubt recommended by superannuated cricketers on TV.

They put 18 solar panels on four or five sections of roof and connect them with a network of corrugated conduit tentacles that look like those of a fearsome deep-sea monster.

There are some things that should never exist, starting with the quintuple-fronted suburban house with portico.

Proper tradespersons rightly deride these maritime nightmares as ugly. However, I like to make the point:

If these installers don’t care how shoddy their work looks, do you really want them making six or eight equally slipshod holes in your roof?

Just look at that gloriously efficient wiring across the roof, as simple as the people who installed it.

The same house just keeps on giving. Conduit snaking along the hip and panels overhanging the frame. Quality so bad that it’s almost good

This example is from the ‘Crap Solar’ Facebook group.

Good Conduit On The Roof

Some electricians believe conduit should never be seen on a roof. I disagree.

Despite the horror-show of flexible cable conduit all over a solar roof, sometimes a short length of rigid conduit is a good idea – if it can reduce the number of roof penetrations required.

As a licensed roofer, I will tell you that there are good reasons not to make holes in the roof, even if you have a proud and skilled installer who knows how to make a proper weatherproof penetration.

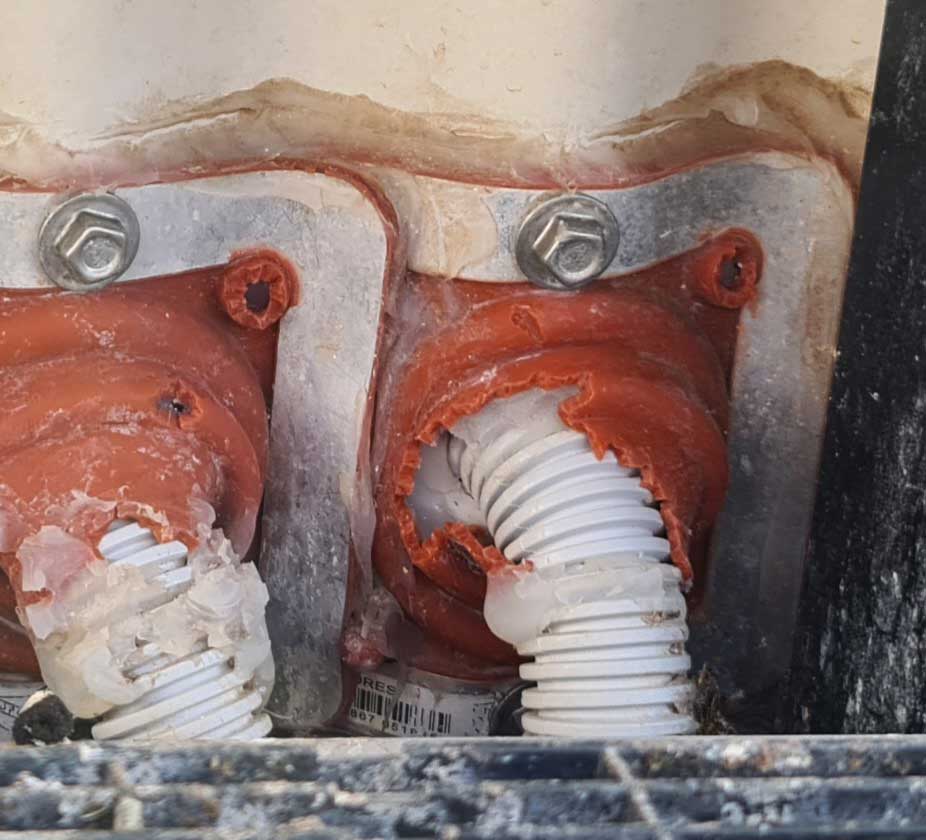

Dismally installed rubber flashings with even more damage from rats or birds.

Using rigid conduit, or better still metal duct, to protect cables from the sun and wildlife is often the best approach.

Rigid conduit custom bent to bridge from one solar panel array to another

This bespoke frame is perfectly strong, placed close to the hip line of this roof, and the wiring placed in custom bent conduit is a simple solution that avoids making holes in the building.

On the Roof: Bird Protection

While we are on the roof, we should explore bird proofing of solar panel installations.

I have diagnosed first-hand examples of Little Corellas chewing clean through solar DC cables.

Yes, that’s a solar connector that should be clipped up out of harm’s way, and yes the birds have exposed the 700 volt live conductors at one end and chewed clean through them at the other.

I’ve also discovered pigeon palaces replete with inches of guano and dead birds.

Bird proofing can be an essential accessory for your new solar install.

If you are lucky enough to have birds regularly visit your roof – be sure to discuss options for bird proofing with your installer.

Carefully Crafted Cable Conduit Conclusion

A good solar installer should never install a mess of cable conduit on your roof – but they may put some short lengths of rigid conduit up there for good reason.

If the thought of even a short piece of rigid conduit on your roof fills you with horror, then make sure you advise your installer that any visible conduit is a no-no and they can design and price the system to suit.

But whatever you do – please avoid the dirt-cheap solar specials. Unless you want to risk a Kraken of cheap conduit emerging from your solar panels once the installer has disappeared.

Image Credit: AI

Next week, I’ll get off the roof and explore the role of conduit at the inverter and battery.

RSS - Posts

RSS - Posts

Hello. Just wondering if you could do a blog about micro inverter panels and their ability to to communicate with batteries. Iv been told that it is difficult. Im having a 15 kw system with maxeon 6 enphase micro inverter panels installed and iv been told that if i use any battery other than the enphase encharge batteries the panels wont be able to communicate to the battery of my choice. Im starting to regret my choice of panels for this reason. i think i should have went with panels that were DC to inverter. not AC from the solar panels.Regards Hans

Hi Hans,

While using an Enphase battery with Enphase microinverters has some advantages, because they can directly communicate with each other, it is 100% possible to use a non-enphase AC coupled battery.

If you have a 3-phase installation – using a non-Enphase battery is more complicated – but still possible.

But there are hundreds of Enphase/Powerwall installations in Australia that work great – including charging from the solar when the grid is down by shifting the frequency to control the microinverter output.

I have a PV system with Enphase microinverters coupled to a Tesla Powerwall 2 battery. I have three phase so the PV system exports across all phases while the battery supplies the house via one phase. It all works fine.

Hi Martin. Thats ok if you want to go with the Tesla Powerwall, but there are numerous other batteries which can put out more KWH than the tesla, for a third of the price. the problem is communication between micro inverter and battery. if some one knows of a solution, let me know. and thanks finn for replying to my blog so promptly. Regards hANS

Any good AC-coupled battery should work just fine with Enphase to maximise self-consumption. They don’t need to talk to each other.

If you want to charge from the solar without the grid – the battery needs to ramp the solar output down when the battery fills up. A good AC coupled battery can do this without communicating with the microinverters by raising the frequency of the AC electricity, which forces the microinverters to ramp down because it is required functionality under the Australian inverter standards.

The batteries do not need to communicate with the microinverters unless you want to see the battery status in the Enphase monitoring.

But the cheaper the AC battery, the harder it is likely to be to get it working reliably.

Thanks again Finn, Now i have the information i need to know, im assuming any competent installer knows this as well. Regards Hans

Always enjoy the SolarQuotes posts and insights! Yes we read them, even try to pass them on, and as educators, even put the info to the solar classes for discussion!

So much to learn and so much changes in our industry that it never rests…

Thanks for what you do!

#SolarTrainingCentre

Yes good article. Especially like the birdproofing comment. Suggestions about that would be appreciated. A checklist for owners to ensure installations tick all the boxes would be great. We almost had our house burn down because of a extremely poor cowboy installation in the early days.

As a roof repairer, the amount of 2 storey houses with pigeons infesting the solar array in western Sydney is horrific, causing health problems and roof leaks.

A major job to clean it away could be prevented by googling “solar panel bird proofing”.

Also the conduit will degrade from UV damage over time and not last the projected life of the array. Similar with the roof top isolaters. I’m very suprised a suitable material is not mandated in the standards.

Any suggestions on how to procet these ABS/PVC plastics from deterioration?

We used to protect ABS/PVC polymers with good old acrylic paint on yachts. Throw two coats of Dulux weathershield over the polymer, and youre good as gold for up to two decades. Add a couple of coats every decade, and youre good for longer than you’ll be alive. Thats the beauty of acrylic products and its resistance to UV

I’ve never really seen much information regarding wind loading on solar arrays. Is there any engineering behind retrofitting panels, particularly those on tilt frames, to existing roofs?

Paint would help or use metal.

Tilt frames have to be engineered to meet Australian standards for the type of installation and the wind zone they are in. The different wind zones are:

A for All Right

B for Beware

C for Cyclones

And D for you are going to Die

If you are in zones A or B it’s not hard to find suitable tilt racks, but that’s not the case for C and D,

Thanks Ronald.

I’m in B-zone, but in a N3 rated location. I have 29 degree tilts on the roof and 16kw of them. They’ve been on for 18 months and through some decent storms. A decent westerly gets up to around 70km/hr. So far so good, but I was wondering about what engineering standard extent TO the house structure and not just the frames themselves. I assume the simplest solution would be that the standard mandates that the frames would fail before the roof structure of the house does!

Good question about the attachment to the roof. Generally speaking, the stronger the expected winds, the greater the number of attachment points solar mounting hardware will require. This applies whether it is a racking rail for a standard rooftop installation or tilt racks. I’ve seen photos where entire roofs have come off buildings with solar panels still attached. But — hopefully — the solar panels did not contribute to this. It’s normally updraft that takes a roof off in a storm and the additional weight of solar panels on a roof can help resist this.

I hope you’re right about that roof coming off regardless of panels!

A quick calculation for me is that I have 44 panels up there at 1775 x 1038 x 35mm.

That’s 81.06 m2 tilted at 29 degrees up there in the wind.

So being lazy and plugging the numbers into an engineering toolbox site (https://www.engineeringtoolbox.com/wind-load-d_1775.html) I can get the forces per wind speed (I am assuming this is panels at 90 degrees to the wind direction) and I get (for 20 ms, which is not an uncommon gust at my place):

Dynamic pressure (N/m2, Pa): 240

So per panel, that’s 240 x (1.775 x 1.038) = 442.188 N

Now a 1kg = 9.8 N, so we’re talking 45.12kg for each panel if it was straight up at 90 degrees during a gust.

I’ll be optimistic and say that is reduced by 68% because my panels are at 29 degrees and not 90 degrees.

So each panel is receiving about 14.44 kg of force with a gust of 20ms.

Total wind load is wind load (N): 19454

So we’re talking 1983.75 kg of force for the whole system (if it were at 90 degrees straight up).

I get to a force of 635 kg being applied across all the arrays at once in one of those gusts.

I suppose if you look at it that way, not extreme forces, and distributed laterally and vertically to an extent, and further complicated by eddies and other interference, minus, as you said, gravity.

Hi folks,

Things are a little worse that those calcs would indicate.

The wind load on solar panels is covered in Australia Standards for panels installed close to and parallel to a roof.

But my reading of the section of the loading code that deals with solar panels, excludes tilted roof top panels.

The wind flow around a building is not simple, nor does it have a fixed pattern of flow, swirling and gusting violently. The code requirement for the corner of a gabled roof illustrates this by mandating a factor of three over the load that would be experienced in the centre of the roof (of sufficient extent.)

A PhD dissertation in the US suggested that individual panels (1 m sq or so, might have uplift about 4 times the ‘static” dynamic wind pressure (1/2 rho V sqd), depending on the wind’s direction and the panel’s location. There is a ls a paper from the Cyclone Testing Station in Townsville (TS821) which has some data , (In fact this work was referenced by the Australia code I think.)

But if the panels are still there, so be it.

( PS I have retired, long since but my last position was head of discipline in civil engineering from an Australian university. And this question is one I can’t readily answer.)

good article thanks Anthony, stimulates thought and discussion, hopefully raising the bar, keep up the good work