It is currently popular for all the cool kids to be down on the chances of the United States remaining a driving force in world history. People are saying it has lost its way and only faces turmoil now Batman has passed away and Seinfeld has refused to hug Kesha.

But I have faith in the land that gave us Jim Henson and Ben & Jerry’s Chunky Monkey ice cream. I think America still has plenty to offer the world. Sure, maybe nothing as good as Muppets and Chunky Monkey, but still some pretty neat stuff. For example, SimpliPhi batteries.

SimpliPhi makes a range of batteries, but what Australians are most likely to be interested in are the two most suited for household storage — the Phi 2.6 Smart-Tech battery with 2.6 kilowatt-hours of nominal capacity and the Phi 3.4 Smart-Tech battery with 3.4 kilowatt-hours of nominal capacity. Both have 24 and 48 volt versions.

These batteries are lithium Iron Phosphate (LiFePO4)1 which is the safest and most durable lithium battery chemistry.

SimpliPhi says their batteries are non-toxic. The US Federal Aviation Administration (FAA) rates them as safe to be carried on planes and they are used by the US military.

These batteries are proudly 100% American made. Except for the actual battery cells themselves. My guess is they’re made in China. But that almost goes without saying these days.

The Phi 3.4 Smart-Tech battery costs around $5,150 uninstalled. When fully cycled once per day to a 100% depth of discharge, the cost per warranted kilowatt-hour comes to 46.1 cents.

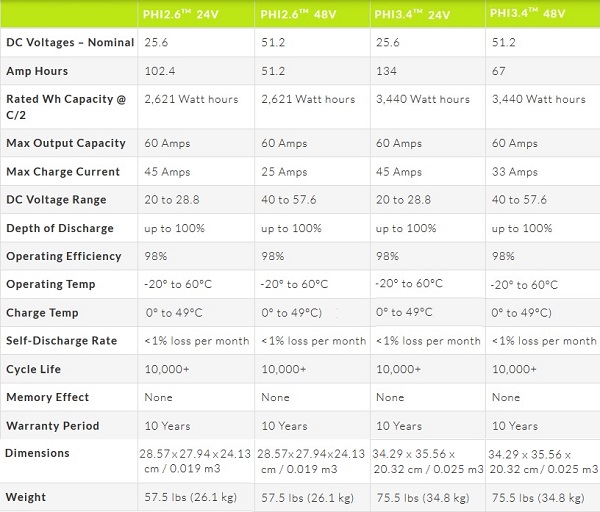

Technical Specs for the PHI Smart-Tech 2.6 And 3.4

Here are the technical specifications for the Smart-Tech batteries. The most popular one is likely to be the 48 volt Phi 3.4 which is on the far right. Note that if you want to keep their written warranty, apart from charging the 48 volt Phi 2.6, you won’t be able to charge and discharge them at their maximum rates.

The SimpliPhi Company

SimpliPhi is an American battery maker headquartered in Ojai California which is between Los Padres (The Parents) National Forest and Mira Monte (Look! A Mountain!).

However, despite being in California, they are actually a Delaware company. Strangely enough, no matter where they are actually located, most American companies are incorporated in Delaware. I assume this is to commemorate the spirit of their warrior ancestor, George Washington, who crossed the Delaware River on Christmas Day, wearing a set of false choppers made from slaves’ teeth, to drive out the Redcoats. So I can only guess he was some kind of reverse Santa Claus or possibly tooth fairy.

Washington is the one standing up in front.

Or maybe American companies are incorporated in Delaware as a tax thing. Either one.

SimpliPhi got its start in 2001 after its founder, Stuart Lennox, got an e-bike company to make lightweight battery packs to power cameras and lighting for the TV and movie industries. They worked so well he founded the LibertyPak company in 2002 to meet demand for them. LibertyPak became SimpliPhi in 2009.

In order to cut the amount of heat camera operators were exposed to by their battery belt packs, they changed to the safer and more efficient lithium iron phosphate batteries SimpliPhi uses today. Their battery packs are now very popular in the film industry, and here is a video showing the glowing costumes they powered in the movie Tron Legacy:

Of course, the tragedy of that movie was they didn’t also give the job of writing the script to SimpliPhi.

In addition to the movie industry, SimpliPhi batteries are also used by the US military as a lighter, longer lasting, and safer alternative to lead-acid batteries.

Smart-Tech Battery Capacity

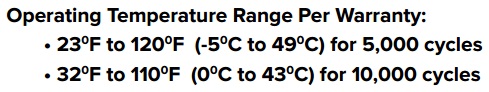

The nominal capacity of Smart-Tech batteries is pretty straight forward. It is 2.6 kilowatt-hours for the Phi 2.6 and 3.4 kilowatt-hours for the Phi 3.4. If you want their warranty to last for the first of 10 years or 10,000 cycles you can only use 80% of that capacity.

But no one using the batteries for normal home storage is going to come anywhere near to cycling them 10,000 times. It’s almost impossible. Most people will cycle home batteries 0.8 times a day or less. As a result, there is no reason not to use the warranty condition that covers the first of 10 years or 5,000 cycles and which allows them to be used at their full capacity. This lets them be cycled an average of up to 1.37 times a day and maintain their warranty for its maximum length of 10 years. It’s very unlikely a household would cycle them more than that, and if they do, they are probably doing something wrong, such as using an undersized rooftop solar system.

So for home battery use, unless your needs are really weird, they can be used at their full capacity and still have a 10 year warranty.

Smart-Tech Battery Power

When the words America and power come together in the same sentence, Australians of a certain age automatically think of one thing — Austrian body builder Arnold Schwarzenegger.

“I’ve got wood. This is a joke in America, yes?”

Arnold Schwarzenegger embodies all that is best about the United States. Their willingness to take in people from other countries no matter how bizarre they look, how strange they sound, or how evil their home country’s government used to be.

From his humble beginnings as a steroid abusing exercise freak, Schwarzenegger went on to become one of the most powerful men in the country. And then gave it all up to become governor of California.

https://www.youtube.com/watch?v=hodbKW5VLf8

But when it comes to solar battery systems, we’re not talking about muscular power, star power, or political power. Instead we are talking about how many kilowatts of electrical power they can give.

According to their technical specs, the maximum output capacity is 3 kilowatts for the 48 volt Smart-Tech batteries and 1.5 kilowatts for the 24 volt ones2.

But if you want to maintain their written warranty, they can only give half that power. That’s 1.5 kilowatts for each 48 volt battery and 0.75 kilowatts for each 24 volt battery. That’s a little disappointing, but for the 48 volt ones it’s still more power per kilowatt-hour of storage than the Powerwall 2.

If you wish to stay within the warranty conditions, the charge rate also has to be the same as the discharge rate.

Operating Temperature

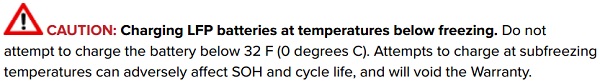

According to the technical specs, the operating temperature of Smart-Tech batteries is from -20 to 60 degrees Celsius.

But there is something very important you have to remember about this operating temperature range, and that is you can’t necessarily use the battery within it. The warranty quite clearly states:

Now you might think that clears things up and the operating temperature is really 0 to 43 degrees for a 10,000 cycle warranty and -5 to 49 degrees for a 5,000 cycle warranty. But it’s not that simple. The warranty also says:

So if you have a 5,000 cycle warranty you can charge the battery at -5 to 0 degrees, just so long as you don’t charge it at below zero degrees because that will void the warranty? Who wrote this warranty? Kafka?

The good news is, unless you live in an unusual place, the temperature of the battery is never likely to go below zero in Australia. Especially since they are indoor batteries. Even if the air temperature dips below freezing, the battery’s thermal mass means it probably won’t. Because the 5,000 cycle warranty is suitable for home storage, its maximum temperature of 49 degrees is not likely to be a problem, provided the batteries aren’t in direct sunlight.

Size, Weight, And Where You Can Stick It

The SimpliPhi Smart-Tech batteries are fairly compact. At 34 cm wide, 36 cm high, and 20 cm deep, the Phi 3.4 is about as wide as the cruddy old laptop I am typing this on and not as deep. It has a bracket that can be used to mount it on a wall. It’s not light at 35 kilograms, but you are not meant to lug it around with you. SimpliPhi makes other stuff for that:

The LB 640 Liberty Belt is made for the film industry, mining, trade work, medical and emergency use, and for winning on cattle prod night at Fight Club.

The Phi 2.6 Smart-Tech battery is three-quarters the size and three-quarters the weight.

The batteries will need to be installed inside. Their enclosure rating is IP32, which means they need to be kept away from water and dusty environments.

Efficiency Is A High 98%

The Smart-Tech battery’s efficiency when charged and discharged at the maximum rate their warranty allows, is around 98%. This is about as good as you are likely to get from a battery and means they produce very little waste heat. Unfortunately, the inverter they are attached to will result in more losses. This will vary, but may be around another 5%.

The fact they produce so little waste heat means cats are much less likely to develop the habit of draping themselves across them, which is an extra safety feature I don’t think anyone else has mentioned.

The Warranty Is For 10,000 Cycles — Or 5,000

The Smart-Tech battery warranty is extremely good, provided nothing ever goes wrong with the battery.

While the written warranty doesn’t make this crystal clear, I have double checked with SimpliPhi and there are two warranty conditions:

- The first of 10 years or 10,000 full cycles with 80% depth of discharge.

- The first of 10 years or 5,000 full cycles with 100% depth of discharge.

Under both conditions the batteries are guaranteed to maintain at least 80% of their original nominal capacity.

A warranty that lasts a full 10 years under normal use is excellent for household batteries and one more bit of evidence that lithium iron batteries are likely to dominate in the home energy storage market.

SimpliPhi says the batteries will still be useful once they have fallen below 70% of their original capacity, but once they go below 65% they’ll be on their last legs.

Battery Capacity No Longer Needs To Be Twice Inverter Capacity

Until Friday, the Smart-Tech batteries’ warranty required the battery capacity to be at least twice that of the inverter it was attached to. Presumably to make sure the batteries would never be charged or discharged too rapidly. I asked SimpliPhi about this requirement and pointed out it kind of sucked. They responded by changing their warranty so it’s no longer necessary. Getting companies to change their warranties is just one of my superpowers3.

That was a pleasant surprise. It’s refreshing to see a company that’s flexible enough to rapidly respond to fix a problem that’s pointed out to them. (Some companies never change. No matter how many times I point out they’re being daft.)

This means, as far as batteries go, SimpliPhi’s Smart-Tech ones are fairly ideal for households that want to use a small amount of battery storage at high capacity.

If The Battery Has A Problem, You May Have A Problem

I expect SimpliPhi batteries to be reliable. They are used by the film industry and by the US military, and let me tell you, they don’t muck around. If a camera operator has a battery failure, the director will not stop short of making a scathing remark. She may even resort to sarcasm. Clearly only the most reliable of batteries will suffice in that situation. My understanding is the US armed forces also have high standards.

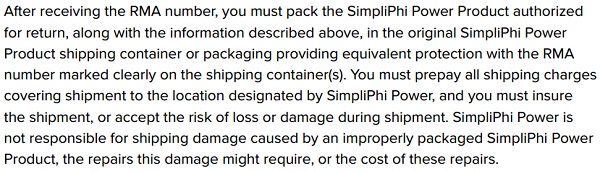

So I don’t think it’s likely you will have a problem with a Smart-Tech battery, but if something does go wrong, then you may have a problem. The warranty says SimpliPhi will send someone to try to solve the problem on site, and if that doesn’t work, SimpliPhi will provide you with a “Return Material Authorization” number or RMA. Then, according to the warranty, you must do the following:

In other words, if their product fails to operate as promised, you have to pay to ship it to them. This is not good enough. If you have paid to have a SimpliPhi battery installed, then you made an agreement with the installer for them to provide you with a working battery. If it stops working within the period it is warranted for, or before a period it could reasonably be expected to operate for has passed4, then they have a responsibility to provide you with a repair, replacement, or refund without charging you money.

I asked SimpliPhi about this. My exact words were:

“If a smart-tech battery has a problem that can’t be fixed on site, will anyone in Australia be required to pay to freight it to a designated location?”

And their exact reply was:

“If a battery cannot be fixed on site and it is confirmed as a warranty issue a replacement will be arranged and the faulty unit to be shipped to the manufacturer for analysis.”

It’s great that they’ll provide a replacement, but they still didn’t make it clear if they expect you to pay to have it freighted to them.

SimpliPhi Is Reducing Emissions — A Bit

SimpliPhi and its partners, are doing their bit to reduce emissions and they say so on their homepage. In fact, they may even be reducing emissions by more than my parents are! Beneath a teeny tiny picture of the planet earth, they state the following:

Wow, 13,680 pounds! That’s over 6.2 tonnes! It would take 5 kilowatts of north facing solar in Brisbane around a whole year to do that!

It’s a little disappointing SimpliPhi required partners to help them cut emissions by as much as one fairly typical sized rooftop solar system in Australia, but the important thing is they cut emissions rather than increased them. This is because batteries don’t decrease emissions in most of the world at the moment, but do the opposite. This will change in the future, but it is currently the case in Australia5. I’m glad SimpliPhi has reduced emissions rather than increased them, but I have no idea how they reached this figure.

SimpliPhi Batteries Appear Extremely Reliable

Smart-Tech batteries are lithium iron phosphate which gives them an edge in both safety and reliability over other types of lithium battery chemistries, including those used in the Tesla Powerwall 2 and LG Chem RESUs. Their years of use by the film industry and by the US military suggest they are a very reliable battery. Given the information I have, if reliability is what you are looking for in a lithium battery, then SimpliPhi Smart-Tech batteries should definitely be a good choice.

Just don’t let them make you pay for any goddamn postage6.

Footnotes

- SimpliPhi calls them lithium ferrophosphate batteries or LFP for short, because they apparently like using the Latin word for iron. ↩

- All the Smart-Tech batteries have a maximum output capacity of 60 amps. The 48 volt batteries have a nominal voltage of 51.2 volts. 60 amps by 51.2 volts gives 3.072 kilowatts. The 24 volt batteries have a nominal voltage of 25.6 volts. 60 amps by 25.6 volts gives 1.536 kilowatts. ↩

- …ladies. ↩

- In Australia you are protected by Consumer Guarantees that apply no matter what the written warranty or salespeople may say. ↩

- With the potential exception of homes that have been export limited. But if a household has rooftop solar and batteries the reduction in emissions from rooftop solar will far outweigh the increase from using batteries. ↩

- Or rather, since SimpliPhi Smart-Tech batteries can’t be sent through the post because they are both too heavy and sending anything but very small lithium batteries is prohibited, don’t let them make you pay to have them freighted. ↩

RSS - Posts

RSS - Posts

The term “lithium ferrophosphate” is inspired, I think, as it avoids the inevitable confusion between “lithium ion” and “lithium iron …” Add that the chemical shorthand for “lithium iron phosphate” is LiFePO4 (subscript 4), then they’re well ahead on rationality with their term.

If it’s good for mobile use, I’d use the 48v one for a DIY electric mower (kept in the garage on cold nights). The “80% discharge limit” seems to make them equivalent to Redflow’s Z-Cell, in that it can be 100% discharged (needs to be now and then), but only returns 80%. (With a sufficiently large PV array (free fusion power) the constraints are interchangeable, I reckon.

At $15.5k for 10 kWh, this neat LiFePO4 battery is not cheap – but then I’m not across the current price of the 10 kWh Z-Cell. That seems to be the minimum useful for my impending off-grid treechange. (There’s always the generator, though.)

I’m much attracted to a DC-coupled system architecture, with just MPPT charger, battery, and battery inverter. But both SimpliPhi and Z-Cell require charge current limiting, while a high level of power bypass on the DC bus, directly from MPPT to inverter, is highly desirable. Soooo … a chage current limiter between DC bus and battery would probably confuse the bulk/absorption/float logic in the charger, I guess. Might need a firmware tweak for the use case.

Lithium ferrophosphate is a better term, but for some reason lithium iron phosphate, or worse, simply lithium iron seems to be commonly used. They are definitely able to be used for mobile applications. China has maybe 2 million electric cars using them.

There’s always a nitpicker. LFP is generic.

https://en.wikipedia.org/wiki/Lithium_iron_phosphate

Sony’s “Fortelion” cells are olivine, but some aren’t.

I know you have written that batteries don’t reduce GHG, based upon

the embodied content, and the waste of inneficiency, but surprisingly, there is more to it than that.

https://phys.org/news/2017-01-solar-power-energy-consumption-emissions.html

Thanks for that. I presume people who have invested in both solar PV and battery storage will often think they have done their bit for the environment and so no longer feel as concerned about conserving energy.

So any info on pricing?

Around $5,150 for the Phi 3.4 Smart-Tech battery.

Imagine the cost of a BYD e6 EV if the LFP batteries in them cost even half of the $1,500 kW asked for the Phi 3.4 battery.

There are many serious discrepancies in the prices being asked for lithium batteries – it is going to take a long while for prices to be sorted out.

In case you haven’t seen it:

https://www.solarquotes.com.au/blog/chevy-bolt-electric-car-reveals-cheap-batteries-really/

Did you ask them if they understand their responsibility under Australian consumer law?

for example:

Returning the product:

You are generally responsible for returning the product if it can be posted or easily returned. You are entitled to recover reasonable postage or transportation costs from the business if the product is confirmed to have a problem.

When a product is too large, too heavy or too difficult to remove, the business is responsible for paying the shipping costs or collecting the product within a reasonable time of being notified of the problem.

https://www.accc.gov.au/consumers/consumer-rights-guarantees/repair-replace-refund

BTW It was minus 2 (according to my car thermometer) under my carport this morning when i left for work. I live in NE VIC Not too much of a stretch to imagine the battery going below 0. I guess the solar wont be charging any batteries until later in the morning when the sun gets up a little so it should be good. (should be).

The good part is they do not require an interface to the internal BMS like the LG RESU.

The downside is the user does not have communication with the battery to get Soc and S of life and depending on the Inverter/mppt system current in/out of the battery. To me, this is very important!

They can be stacked but their small capacity size compared to a RES-10 makes them a wiring job to get the capacity. You need 3 chunky monkeys 🙂

Dave Angelini Offgrid Solar

“we go where powerlines don’t”

http://members.sti.net/offgridsolar/

e-mail [email protected]

text 209 813 0060

Erik when you get around to integrating your SPS solution, to maximise efficiency and functionality and extend battery life, I suggest you consider a 600 – 700 VDC PV array DC coupled (via a simplified and efficient charge controller) to a single series bank of VRLA or LiFePO4 batteries operating at around 500 – 600 VDC nominal, of the kWh capacity needed to suit your requirements.

This is about as simple, efficient and reliable as SPS gets with low controls hardware overhead, and the higher voltage system allows for lower current protection devices, controls and associated wiring.

The LiFePO4 batteries are likely to age a bit better than the VRLA but in reality that will depend on how the system controls are setup to enforce a well-considered DOD limits strategy, which makes all the difference of course.

SPS DC coupled battery systems operating around this voltage (rather than 24 – 144 VDC) importantly ensure an almost guaranteed permanent hands off autonomy for essential services (fridge, freezer, light) irrespective of daily weather patterns. This can all be easily scaled up also.

Lawrence Coomber

Many thanks for the suggestion, Lawrence. I can see that a doubling of the battery voltage will reduce the battery inverter’s I2R losses by 75%, and the same for the battery. Going all the way up to a half kilovolt makes for a massive pile of batteries though. As there is a DC-DC converter in between anyway, as soon as you have a MPPT charger, the merit of matching the array voltage 1:1 diminishes greatly, I figure.

I’ll look at the relative costs for sure, but availability of high voltage battery inverters will necessarily be the decider. Not much merit in piling up a lethal high voltage battery bank if I can’t buy a stand-alone HV inverter.

And then I have to address the best method for high power MPPT to inverter coupling, while limiting battery charge current, without confusing the charge algorithm by increasing the perceived battery voltage. (Maybe we _do_ want to flip the MPPT from absorption to bulk phase when a big inverter load kicks in.)

Erik,

Halving the current could reduce some resistive losses to 25%, but the situation differs for the batteries.

Two batteries in series, doubles the voltage, but also doubles resistance,

where halving the current results in a reduction to 50%.

On the other hand, the batteries could be in parallel, so halving the resistance.

The higher current remains, so losses would be reduced to 50%.

The reduction of 50% in both cases, stems from having twice as much battery.

High voltage batteries are riskier. Even a little inductance can cause Intermittent connections to arc. Seems a lot of trouble for little gain.

Athomas – you have touched on the single most important subject there is in DC power electrics and one very close to my heart; arcing.

Most electrical practitioners know a little about AC theory but very few have a solid grounding in DC theory and practice, and particularly DC power electrics. I learned about DC arcing the hard way; by making silly mistakes as a young electrical tradesman (fitter/mechanic) in 1968 serving on a DC powered Aircraft Carrier in the Australian Navy.

DC arcing is frightening and often leads to catastrophic consequences. It would not be common knowledge that a difficult to detect and control arcing incident on the DC powered Aircraft Carrier HMS Ark Royal whilst in dry dock in 1979, led to a catastrophic electrical fire deep within the ships main wiring loom, and as a result she was irreversibly damaged and considered beyond economical repair and decommissioned forthwith.

DC arcing once was a very difficult phenomenon to account for in circuit design as well, but those days are long gone, and best practice solar PV and battery storage designs can totally mitigate arcing by using DC arc fault circuit protection devices, whether it is due to in series circuits faulty connections or terminations, insulation breakdown between conductors in parallel circuits causing intermittent short circuit, or intermittent ground conductor faults.

These devices are a mature science and have been around a while and certainly mandated in solar PV system designs in some countries including the US for over 5 years now. In general, they have been an optional choice only in Australia up to now and it has been left up to the system designer to decide if to incorporate them or not, but that is about to change dramatically because use of these devices will be mandatory in all DC and AC circuits (including all solar PV strings and battery storage strings) as soon as the new update to AS3000 is released later this year.

I discussed this point with an AS3000 committee member just last week in Qld and there will be very few circuits exempt to this new AS3000 industry requirement. It is all to do with electrical safety which is paramount going forward.

Lawrence Coomber

Lawrence, while I have seen brass contacts the size of a finger melted by a DC arc, I didn’t see it happen, so am perhaps not as wary as I might be.

Circuit breakers (and switches) commonly have much much lower DC voltage and current ratings than their AC ratings. (The higher the current, the harder it is to extinguish the arc, and I remember the arc extinguishing chutes on electric trains running at 600 VDC and high current, where an air blast blows the arc out with a loud WHUFF.)

Domestically, where the DC fault current can be high, as with a big battery, I like the idea of a HRC (High Rupture Capacity) fuse. Commonly ceramic bodied and sand-filled, they unequivocally extinguish the arc on rupturing.

Sometimes the old technology is both robust and reliable. (Just keep spare fuses on hand.)

Lawrence, Interesting. Are you suggesting a 500-600VDC battery? This would require +/- 150 cells (at a nominal 3.6V). Are there readily available off-the-shelf charge controllers, BMS’s and inverters for those voltages? Or do you have a more complex architecture in mind?

Great article Ronald!

I am sure the question that everyone is wondering is: Has a battery finally been released that actually saves you more money that it costs?

Would you also be able to crunch the numbers and tell us the payback period?

Given that you are reviewing so many battery systems, I imagine you must have a spreadsheet set up that you can just drop the relevant numbers into 🙂

I wrote about how the Powerwall 2 can’t beat putting the money in a term deposit for any normal household here:

https://www.solarquotes.com.au/blog/powerwall-2-payback/

And that’s using the installed price Tesla gave that may not turn out to be realistic. So until something considerably cheaper than the Powerwall 2 is available batteries won’t pay for themselves under any remotely normal circumstances. While electricity prices are rising, feed-in tariffs are also rising:

https://www.solarquotes.com.au/blog/agl-feed-in-tariff-mb0090/

Which hurts the economics of batteries. I wrote about how the economics of batteries are unlikely to improve with the current round of price increases, and may even get worse, here:

https://www.solarquotes.com.au/blog/when-electricity-price-hikes-dont-improve-the-economics-of-batteries/

Ron, I was considering some generator for back-up (as you suggested in the past). I was looking specifically in the gas generator option and for 13 kW the price was about $ 8,000. I am just thinking aloud to buy it and wait for black out or to buy the solar battery and use it from day 1…tough decision?

Any suggestion?

Well, it will all depend on your goals.

If you want batteries to save you money, it will take time for them to come down low enough in cost to do that.

If you are getting batteries, then a 13 kilowatt generator is much larger than most people need. This is because if your batteries get low you can run a small generator over a long period to charge them up.

While a 13 kilowatt generator will allow you to get through blackouts with hardly any inconvenience, if you just want to run your refrigerator, freezer, TV, microwave, and lights, and do things such as charge laptops, a much smaller generator will do.

So if you want to wait to get batteries you could just get a small generator now and make do with it and once you do get batteries, a small one will be all you need.

Alternatively, you could decide you don’t need a generator at all. This will depend on how frequent and prolonged they are in your location and how annoying and expensive they are for you.

Ilian, $8000 seems way over the odds.

One design issue that is often wrestled with by Off Grid system designers is that they struggle sometimes to understand the important (and cost effective) role that a Genset can [and should] bring to a ‘smart’ system design. Gensets’ are critical components of every Off Grid design even though their role (in most cases) seems to be a minor one looking back on system performance and annual running costs.

Generally I design as standard two Gensets’ for Off Grid systems in one of two configurations:

1. One auto start silent (Honda 3 kW) genset suitable for some normal household plus essential services circuits (fridge, freezer, lights), plus a second manual start genset suitably sized to service a specified and enforced by controls, maximum demand. In general for most domestic/rural premises purposes only, a 12 kW genset is a high end choice, but this can be much less to around 5 kW;

2. Because of normal load switching diversity within a premises, another approach is to install two auto start silent (Honda 3 kW) gensets with linked AC outputs. This setup has the advantage of fuel economy when running one genset when required, but providing for automatic start-up and parallel operation with the second genset if the demand increases above 3 kW.

Importantly the (prime) essential services genset must be able to be integrated into the system control logic and be started when required automatically by the system itself requiring no user intervention as default. Of course these gensets can be manually started at any time by the user. Note that not all commercial gensets offer (start terminals) though for integrators use but there are some reliable options.

If welding is a part of the user requirement there are two ways a system designer may choose to handle this:

1. A dedicated manual start high current welding generator (gasoline or diesel) can be supplied to suit these specific user needs;

2. Standard GPO plug in welders can easily be accommodated by the system PV inverter itself, with some operating rules and conditions enforced by controls on the dedicated welding circuit. One of these rules enforced by logic and controls insists that the welding circuit will be deactivated (and instantly) if the available solar PV resource is insufficient to service both the normal premises circuits demand plus the welding circuit demand. It follows that the welding circuit GPO will always (and instantly) be deactivated when the system battery storage is sensed as being discharging rather than charging. A most important point.

Obviously this is just a brief overview and there is a lot more on the subject of Off Grid / Micro Grid genset integration and management possible for system designers to consider, including how a well-designed, logic controlled genset/solar PV/ battery storage system can be performance optimised with a considerable decrease in both the solar PV and battery storage size being possible, resulting in commensurately lower overall system costs despite a modest increase in annual gasoline running costs.

Above all remember: “Off the grid – a little gasoline when needed – goes a long way”

Lawrence Coomber

Erik and Niels – important points well made.

Here are a few Off Grid / Micro Grid design imperatives that engineers might consider from a contemporary commercial best practice design perspective rather than a DIY perspective which will obviously differ for many reasons, such as the commercial supplier/installer obligations and commitments to provide meaningful system warranties and performance standards guarantees over a long period for example.

1. System long term reliability is underpinned by quality components and ‘smart’ clever design.

2. Power electronics design and manufacturing trends over the last 12 years in my experience as a manufacturer, show that solid state components/devices and power conversion equipment (PCE) are moving quickly to higher DC operating voltages. This is an important step providing opportunities for designers to exploit higher voltage DC input sources including PV and battery storage, by integrating proven quality PCE hardware (PV modules, batteries, converters, gated IC’s, DC input VFD’s, etc) into Off Grid system designs, benefitting through improved system efficiency, functionality, and reliability. Of course there are practical limits that apply even to large scale Off Grid and Micro Grid solutions and considering the current format solar PV and energy storage technologies that we are all aware of, around 1500 VDC is that practical limit, but this will evolve further also over time.

3. A reliable and high performance Off Grid system should be considered a ‘critical supply service generator’ and (generally) should operate autonomously without requiring user intervention. To this end, it will be a semi intelligent (black box processor controlled) system with real-time adaptive decision making and control capability, interfacing with an array of system sensors and transducers providing for feedback and feed forward logic control. Independent remote monitoring and control connectivity (both SMS and Web) is essential. In general terms, Off Grid systems should emulate the traditional Grid.

4. A fully featured Off Grid system design (without consideration to a backup genset) importantly should be capable of guaranteeing permanent autonomy (24/7 x 365) under near worst case circumstances, to a minimum performance standard of servicing essential services circuits (fridge, freezer, light). This is a key performance metric able to be designed for in part through exploiting higher DC voltage battery storage and DC coupling, along with strict enforcement and control of battery storage key management parameters DOD, SOC plus load shedding logic in place.

These imperatives if met will ensure that a reliable high performance system can be installed and with it, confidence for both the system user and installer going forward.

Regarding MPP, charging and inverter coupling; one of the unique attributes of PV that we are all familiar with, is that PV is a nonlinear variable current limited generator and thus can function like a traditional CC/CV battery charge controller and precision BMS when some gated power control IC’s are added. This abstract point is irrelevant to On Grid / Hybrid system designers because the Network operator will not permit On Grid system islanding outside of its own control regime, plus traditional On Grid battery storage units are pre-assembled generally with intrinsic battery charging and management smarts. On Grid / Battery hybrid systems will likely become highly problematic for many reasons for the Grid operator as their popularity increases.

Off Grid designers however are integrators in the true sense, and able to take full advantage of this very useful PV attribute and exploit it quite precisely in a DC coupled charging system, which is an improvement on the traditional controller and BMS design, is robust and fit for the purpose, does the job required safely and repeatedly, and comes with an economical low hardware overhead in both circuit protection and isolation controls.

There have been numerous scientific reports published over many years on this subject and the key take-away points from them collectively can best be summarised:-

(1) Direct DC coupling of solar PV and LiFePO4 battery storage can be optimised by the correct system sizing design of solar PV and battery storage, and matching the MPP voltage of the solar PV (at the PV operating condition) to the maximum charging voltage of the battery storage (as specified by the system designer).

(2) Over voltage battery charging detection and isolation control logic (typical BMS) should be designed for and installed separately to the normal battery over current and fault protection isolation controls such as circuit breakers and fuses.

(3) Best system performance results can be achieved by designing a system where the solar PV MPP voltage is very near but slightly below the maximum desired charging voltage of the battery bank, which will result in normal operating conditions to a (full or near full SOC) in a well sized and logic controlled system. An important attribute of LiFePO4 cells is that they do not need to be charged to 100% and will function without detriment at all in partial state of charge operations.

By global standards Australia does not have a thriving Off Grid sector happening just yet but this is changing. Regarding CEC and CER approved SPS inverters, there are some listed up to 30 kVA specified for Off Grid and Micro Grid use at up to 705 VDC. A further six 3 phase models (40, 50, 60, 75, 100, and 125 kVA) will be listed later this year.

Modular high quality ‘plug and play’ LiFePO4 battery storage units at any nominated nominal voltage and capacity are readily available for designers/installers.

Lawrence Coomber