Phono Solar have only gone and drilled holes in their new solar panels…

If you want a solar cell to produce electricity then it’s important to let the sunshine in. Specifically, into the solar cell. Not letting the sunshine in is a bad idea. Despite how very important this is, most solar cell manufacturers place a fine metal wire grid on top of their cells that blocks around 5% to 6% of sunlight falling on them, for no other reason than they don’t work without it. It appears the metal grid is necessary to make electrical contacts required for current to flow.

One way to reduce the amount of light blocked by the electrical contacts on the surface of cells is to use Metal Wrap Through technology, or MWT for short. Instead of having wires run across the surface, a “laser” is used to cut holes into cells for electrical contacts and very fine wires called “fingers” radiate across the cell from them. Compared to using a grid, this method halves the amount of light blocked.

While MWT cells have been made since at least 2010 and panels since at least 2013, they have never really caught on. I’ve never seen one in Australia. But this may be about to change. Phono Solar introduced its new MWT panel at the Tokyo solar conference in March this year1 and it should be arriving in Australia in the near future.

Because MWT provides an efficiency advantage at a price that appears to be cost effective, more manufacturers may follow Phono’s lead and provide MWT panels in the future. While I don’t know if this technology has legs, I can say it definitely has “fingers”.

How Solar Cells Work

When light hits a suitable piece of silicon or other semi-conductor2 it can cause electrons to be knocked out of the atoms they were hanging around. This is apparently very thrilling for them, because after it occurs they are called “excited electrons”. By adding tiny amounts of right elements to the top and bottom sides of a silicon wafer, a junction can be formed that stops electrons that are knocked below it from going back to the atoms they came from because of magic — I mean physics.

But if a metal conductor is attached to the top and bottom of a solar cell, electrons can travel along it from the top to the bottom to where they can then do it all over again if they like. On the way, as they are traveling through the conductive wire, they can be made to do work, such as powering an LED light, charging a laptop, or passing through a solar inverter that will change their direct current (DC) to the alternating current (AC) the grid uses.

How MRT Solar Cells Work

The metal conductors on top of a solar cell are a problem because sunlight has a hard time passing through metal. If you ever come across light that easily passes through metal then what you are probably dealing with is not sunshine, but some kind of “laser“.

SunPower solves this problem by putting a transparent conductive layer on top of the cell instead of wires. They do this with their X and E series panels and LG Solar appears to do the same with their NeON2 R panels. Unfortunately, while it works well, this option is not cheap. Another solution is to use small solar cells that overlap, so the electrical contacts of one cell are covered by the cell on top. This method is used by several manufacturers including SunPower in their Performance Series panels:

An example of overlapping solar cells in a SunPower P-Series panel.

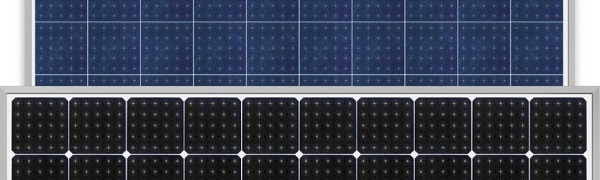

MWT doesn’t prevent all shading from electrical contacts, but it does cut it by around half or more. This is done by eliminating the need for the thickest wires that run across the top of a cell called busbars. Instead of having them on the surface, Metal Wrap Through wraps metal through the solar cell by cutting holes in it with a “laser” and placing metal electrical contacts in them. From the contacts spread extremely fine metal wire “fingers”.

The Phono MWT cells have 25 holes each. As you can see below, this makes them look rather dotty:

In case you are wondering, these are not quantum dot solar cells. Quantum dots are less than half that size.

Potentially Half A Percentage Point Efficiency Improvement

MWT can increase the amount of light entering a solar cell by 2.5% or more. For a 16% efficient panel a 2.5% increase in sunlight entering cells increases its efficiency to 16.4% and would increase an 18% efficient panel to 18.45%.

MWT Improves Heat Tolerance

Lasering 25 holes through a solar cell and stuffing them with highly conductive metal is apparently very useful for transferring heat from the surface of a solar cell to the back. Phono says:

“…the operating temperature is 3-5 degrees Celsius less than that of the traditional modules, which allows an additional 2% power generated.”

This means if a typical solar panel has its efficiency reduced by 0.4% for each 1 degree increase in temperature about then MWT panels should only have their efficiency decline by about 0.3%3.

MWT May Save On Materials

MWT panels are not a new idea. People have been working on them and producing them for years now, but so far not a great deal has come of them. A major reason why it can take so long for advances that work in the lab to take off in the market is because it is often difficult to work out how to mass produce them cost effectively. An important part of this process is often lowering the cost of materials used.

Phono claims its MWT panel reduces the need for silver paste4. If this is correct, it’s an important development as one of the disadvantages of MWT cells used to be they required more silver.

MWT cells also apparently suffer less breakage during panel manufacture, which is another useful way of lowering manufacturing costs.

Provided both material and manufacturing costs aren’t much higher than those of standard panels, then MWT will be able to compete with other methods of improving efficiency. While overlapping cell panels are capable of slightly higher efficiency because it is possible to make them so they don’t block any light, they do have the added expense of requiring extra silicon because of overlapping, so it will be interesting to see which method will win on price per watt.

MWT Panels Look Pretty — If Installed 3 Feet From Your Face

Phono’s MWT panel looks very pretty close up. Here’s a picture provided by Phono which for some reason only has 16 “laser” holes per cell instead of the 25 their other panels do:

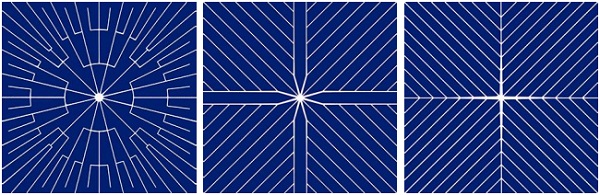

The fine wire “fingers” surrounding the contacts in the holes look kind of like little snowflakes or maybe coral polyps. Phono says the patterns can be customized to suit people’s preferences. Here are some examples from 2013 by Tianwei New Energy:

Don’t they look wonderful? Wouldn’t you love to be able to customize solar panels like this if you were some kind of nutter in the habit of installing solar panels three feet from your face?

Should You Buy MWT Panels?

While MWT panels haven’t taken off so far, maybe their time has arrived and we’ll soon see multiple panels with the technology appearing on the Australian market. So you may be wondering whether or not you should buy MWT panels.

Personally, I say you shouldn’t really care whether or not a panel is MWT.

Not many people in the market for rooftop solar are experts on the technology. To expect the average person to decide whether it is better to put grids on solar cells, laser holes in them, overlap them, or slap a transparent conductive layer on top is basically nuts. Most people simply don’t have the background required to judge the benefits of different types of solar panel technology.

But what anyone can do is:

- Look at whether or not a panel is tier one, or if it’s not tier one, if it is made by a company with an excellent reputation.

- Look at a panel’s warranty.

- If generating the most electricity possible from a limited amount of space is important, you can look at efficiency.

- If you are diligent, you can even check how they are affected by heat.

- And of course, there is the price per watt.

Taking Phono’s claims at face value, their MWT panels certainly tick the top 4 bullet points. If Phono announce competitive pricing, these holey panels may end up ‘Robin’ market share from the premium end of the market currently dominated by Sunpower and LG.

Footnotes

- At least I assume they did. I wasn’t actually there. To my shame, I got stuck in a pachinko parlour with a couple of freetas. ↩

- Before I studied physics I knew trams and trains could have conductors, but I never knew semis did. ↩

- If you want to know how well a panel handles heat, look up its datasheet and find the “Temperature coefficient of the maximum output power“, which may also be called “Power Temperature Coefficient”, or often just “Pmax”. A typical figure is -0.4% while -0.3% is considerably better than average. This is how much a panel’s efficiency is reduced by each 1 degree increase in temperature over 25 degrees. ↩

- Silver paste is expensive, but it is used because silver is the best conductor of electricity. The closest thing to silver is of course the Lone Ranger’s butt and that is in short supply. ↩

RSS - Posts

RSS - Posts

Speak Your Mind