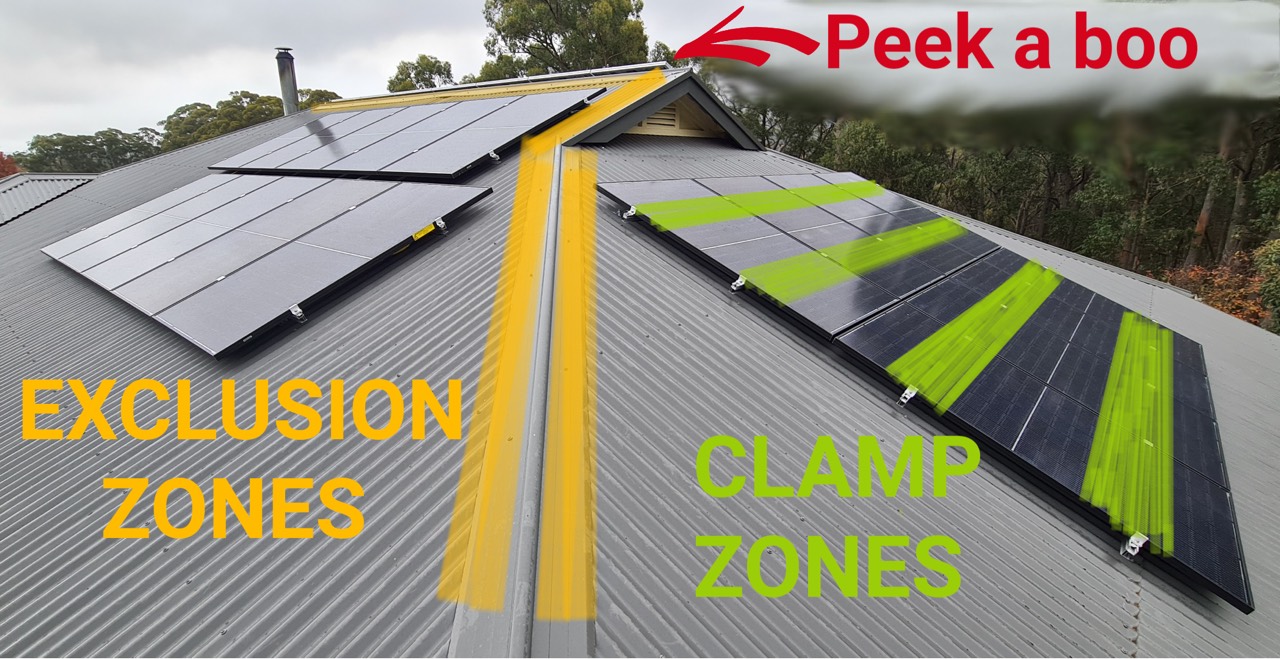

When it comes to installing solar arrays on buildings, one particularly edgy subject is exclusion zones. It seems nearly every solar framing system has copied their competition’s homework. So when it comes to the edge, hips, ridges or gables of a roof, 200 mm is generally as close as you can go; at least according to the framing installation instructions.

And because AS5033 – the Australian Standard for solar installations – dictates you must follow the manufacturer’s instructions, what the manufacturer says must be followed.

That also includes the solar panel manufacturers’ installation instructions; which will mandate ‘clamp zones‘: the areas of the panel that can be clamped.

What’s that peeping over the top of the house? Why, it’s legacy solar of course.

This post will focus on exclusion zones.

Conservative solar installers say no part of any panel shall ever enter this zone where danger lurks, and often err on the small side when designing your solar array – for fear of encroaching the exclusion zone by even a centimetre.

Your more pragmatic installer, looking to maximise the solar potential of the roof, will measure up the available space and make decisions that could open them to lively conversations with other electricians, or worse – a black mark from an inspector. But as always, there are a few factors to consider.

Solar panels have suffered model creep. Like cars, they grow bigger and heavier every season – to the point the latest Toyota Corolla could swallow the original Corolla whole, burping like a bloated toad. The solar panel form factor is pretty standard; these days a little over 1 m wide and either 1.75 or 2.1 m tall. Roofs aren’t so consistent. When you have limited space and very coarse increments of coverage, there is often a very good case for pushing the boundaries on exclusion zones.

This leads us to solar, the tradespeople who install it, and the spirited debate (or bitching) that occurs when AS5033, various building codes and manufacturers’ specifications collide headlong with the supreme overarching requirement – “but what does it look like from the street?”

Exhibit A: Bent rules

Aesthetics is one thing; generating 88 kilowatt-hours a day is something else… for this customer, it’s function over form, and he couldn’t be happier.

Exhibit B: Mulched Rules

Clamping and exclusion zones were briefly considered here, but soon went the same way as the tree in the front yard.

For the want of one corner on one solar panel poking toward an angled hip (which might preclude two panels for electrical reasons), you can lose 350 kWh per year in yield. Things can be dramatically worse if, say, your chosen roof plane is 3.8 metres tall, and you lose half your proposed system for the want of 100 mm.

Landscape Panel Orientation Can Often Help

What about landscape? Often the choice of a better class of installer, running solar panels in landscape orientation (and support rails vertically) means you have greater flexibility in module placement. There’s lots to recommend it, more fixings into the building for strength, modules better supported with structure right where it needs to be (they call it a clamping zone).

But with more parts, it takes more time to execute and aesthetically leaves you with more rail ends and brackets hanging out the bottom and top edge of the array.

As an example, if we have a theoretical roof plane 3.8 m tall and 5.8 m wide, 9 modules in landscape has a nice conservative footprint of 3.3 x 5.25. If we make this array into a portrait install (and there are roof purlins to support it), 10 modules cover 3.5 x 5.5 m, leaving the array 50mm “over the edge” and technically non-compliant, despite actually still being inside the statutory limits for purlins that your iron roof is screwed to.

Bear in mind you might come home to find the roof isn’t screwed to the house if you’re in Queensland…

Image: The Guardian

If we took the landscape array mentioned and then, just for giggles, added an extra three modules across the top, these would be half a solar panel hanging over and above the ridge of the roof. And there would be a lot of pearl-clutching, wailing about aesthetics and cries of exclusion zone non-compliance, mainly by those electricians who aren’t in receipt of the much-improved electricity account, or possibly the neighbours.

Overhangs or pitched angle frames require council planning permission plus third-party engineering on the frame and the building these days, so I couldn’t possibly recommend1 such an approach. However, I could point to dozens of examples that are still firmly attached to the roof after 10+ years. In fact, it’s been observed by a few installers that during extreme weather events such as cyclone Yasi, not only have the solar modules held on, they appear to have held the roof on too.

It was hot in the shed. Inspired by the LandRover that he was always working on, Gerald decided a tropical roof would be a useful layer of insulation. His thoughts didn’t extend to water sluicing off the panels or ever cleaning the gutter.

Creativity (And Coffee) Required

I have experienced first-hand the installation day drama of an incorrect measurement, a new air conditioner or, most recently, a change in panel spec that required 12% more roof space to meet the contracted system size. For the record, it was 36 modules, 13 kilowatts of solar panels, on four roof planes, powering two inverters and a future battery and electric car. Phew.

Overcoming exclusion zone challenges on a small retirement home sometimes requires a little creativity, some extra material or a relaxed interpretation of the book. Please remember your installers are there to solve the problems; plying them with coffee helps, loitering doesn’t.

So, what are we to make of exclusion zones? Unless you have site-specific engineering or special framing2, the black letter of the installation manual says there is a 200 mm exclusion zone around any roof plane you own that can’t be occupied by a solar module. Many other obstacles can contribute to available space, including screw lines in a metal roof or immovable ridge tiles.

However, if space is at a premium and you decide, as people increasingly are, you need a big-ass home generation station, it’s best to engage an experienced installer who knows the wind zone, terrain class, local conditions and can make a judgement call on exclusion zones.

Gratuitous overhang probably isn’t worth considering and in many jurisdictions won’t pass audit, but higher quality modules with greater wattage per square metre, along with a sensible approach to the rules and guidelines, can make the difference between a good yield and delightful excess.

Footnotes

- In 14+ years of selling, installing, maintaining and fault-finding solar systems, I’ve heard a few complaints but never met a customer who’s protested, “we installed too much solar!” It’s always quite the opposite. ↩

- As an example I’m familiar with (and gratuitous plug), Solar Depot use a proprietary frame system that actually makes roofs stronger. But like many Australian innovations, sadly it’s being priced out of existence. Clenergy also deserve a shout out here as they will engineer their framing for special requirements. When a solar electrician recently used their hardware to mount a basketball ring on his garage roof, Clenergy saw the photos and produced engineering documentation to certify the installation was good. ↩

RSS - Posts

RSS - Posts

Great article/perspective, agree on Clenergy (uncertain about other as no first-hand knowledge), how about putting panels portrait but long side running with ridge?

Great topic, and very timely.

Thank you.

We have an old system and will need to upgrade soon. Our roof is, um, “difficult”.

Why do they install panels almost flush with the roof. On metal roofs the horizontal support is almost on the. iron This makes it almost impossible to clean the leaf matter from under the panels. This will cause corrosion of the iron as the leaves rot and acid eats into the steel. ((See car bonnet protectors when the leaves are not removed)

Also panels need air circulating to keep them cooler.

Performance should come before aesthetics. Expect to have major roof repairs in coming years which will require removal of panels.

I disagree. It depends entirely on the circumstances.

There are plenty of gutters out there that haven’t been cleaned in 30 years, because leaves are just not a problem in the area.

There are other gutters that need cleaning multiple times per year.

There are also “gutter guard” products with very fine mesh that make cleaning entirely unnecessary, even in areas with lots of leaves.

(Around half our gutters have this, haven’t been cleaned in a decade or so, and can’t be cleaned anyway without removing the gutter guard. On our roof, the sections with no gutter guard do need occasional cleaning out due to leaves blown in the wind. I should have done the lot!)

Gutter guards?

I’m not a fan, as they don’t prevent the seeds in the bird poop germinating in the gutter. You might get less leaves in the gutter, but chances are you will be pulling all that gutter guard off on a regular basis to get at the grass that grows in there anyway.

Do you have Pine trees next door? I do and the needles slip through that fine mesh.

So I took them off, removed the 5+ years accumulation of gelatinous gunk and do my gutters regularly. 😉

“Pine trees next door?”

Nooo, thank goodness.

The leaves we have from various trees are “dispensed” with very well by the fine gutter guard mesh. The only problem areas are the far side of the house- that I did NOT get done, to try to save money.

I regret that now.

Enough leaves blow on windy days to make it a problem.

I have got 150mm half round guttering, with 100mm downpipes to

the leaf filter. I still get leaves stuck.

I am not a fan of gutter guard for the reasons above. I had guard on

the roof before a roof upgrade (after Hail). the 150mm is definitely an

improvement. Before, the dirt accumulated in the gutter making it difficult to clean.

As far as bad design goes, in Lismore they plan to build a 100Kw solar farm

in the Clyde Campbell carpark (a floodway) at 12.9M above normal river height, when the recent major flood reached 14.4M: Anyone want to grab onto

this system to save themselves from drowning in a major flood? Good idea,

water, 1000VDC, & high velocity water. This poor design was passed for approval recently by Lismore Council. (It is part of an EV charger setup)

Btw, there is now a safe isolator for String inverters, made by CQSola in Brisbane. I hope they use that technology in the above project.

regards, Doug

Great article thank you. My experience is installers don’t usually discuss layout options. They say this is THE plan. So it’s good to know there can be options.

There is a full 20 cm of space between my steel roof and the panels. Lots of circulation, and in three years with lots of trees nearby, no issues with detritus under the panels. The panels also block light on the roof keeping our home cooler in summer. Space between the panels and roof is better.

Solar panels have not been thought through. Most installations look ugly and spoil the look of the house. Should not be allowed. Nuclear energy is the only real future source

Let’s give nuclear generation another 66 years to see if it comes good.

Yeah, agree Ronald, maybe in 66 years we will have clean reliable Nuclear FUSION.

If they ever win that battle, it may well indeed be the solution. (But I’m not holding my breath, and won’t be around then anyway.)

Cheers

OMG. Really? Spoils the look of the house?

I trust you’re aware that nuclear is the most expensive option out there, by far!

Even de-commissioning costs at the end of life are as horrendous, and even when nothing has gone wrong.

And then there’s Chernobyl and Fukushima.

Three Mile, Chernobyl and Fukushima were all old school reactors, modern design is absolutely safe now (according to the nuclear energy commission and several honest politicians) and all those pesky byproducts can now be safely stored as sea.

Jack anthony,

“Nuclear energy is the only real future source”

Yes, that great big nuclear fusion reactor that will keep providing enormous quantities of energy for billions of years, and is at a safe distance of approximately 147.1 to 152.1 million kilometres from Earth. ?

https://www.space.com/17081-how-far-is-earth-from-the-sun.html

Unlike the very much shorter-term finite supply and increasingly more expensive costs for nuclear fission reactors using high-grade uranium ores on Earth, that will likely be fully exhausted within this century.

https://www.solarquotes.com.au/blog/campbell-newman-nuclear-mb2380/#comment-1394013

And if you are advocating for thorium-derived energy, I’d suggest you read about the many challenges at: https://www.oecd-nea.org/jcms/pl_14930/introduction-of-thorium-in-the-nuclear-fuel-cycle

And I just love the aesthetics of a beautiful nuclear plant glistening in the morning sunlight generating all that green energy whilst I gaze fondly at its magnificent artistic structure during my morning coffee on the patio

Jack – that’s madness. The lead time for a nuclear power station is currently over a decade and it’s also the most expensive source of energy available. If we’d built them 30 years ago…

I do not know whether I am blocked from posting to the blog, but, two posts that I have subm,itted, have not got through.

Yes. Nobody cares about WA. I thought you guys were going to dig a ditch and succeed from the rest of Australia?

Hi Bret

I don’t know if your comments didn’t appear for these reasons but reasons why comments may not appear include: too long, off-topic, potentially defamatory, incoherence, strange obsessing over whether people are left or right-handed (been getting a lot of that lately), spam, spam, and more spam. I also can’t rule out technical glitches because there are large parts of the internet we don’t control. Finally, I sometimes don’t approve a comment because I don’t want it to go up without a response from me but then I never get back to it due to limited time.

This is somewhat terrible advice. In no instance should your installer be making a “judgement call” on what is in the installation requirements. If they are, run. This should only ever be done with an engineering assessment. There are two reasons for this. 1. Wind pressures are at their highest at the edge of the roof. This is also heavily geometry dependent. Thus, to avoid assessing all the combinations, the manufacturer would have assumed a reasonable setback to minimise this impact. 2. In QLD, NSW and VIC, under their building legislation this constitutes engineering advice. Unless they have done an engineering assessment themselves and are appropriately qualified, or paid for one by others, they are in breach of those acts and could be found liable in the event of a failure.

Matt,

Thanks for the comment. If you would like to write a short post explaining why exclusion zones should never be violated, (ideally with an example of where it has caused problems) we’d be happy to publish it.

Finn

Interesting debate on exclusion zones.

There are a few important issues as follows.

1. Asthetics.

2. Extra wind loads from encroaching on exclusion zone

3. Warranty on the panels and strength.

1. Nothing looks like a botched job of design and planning when the panels encroach on the end zones of the roof ridges. Firstly the panels sit 100-150 high off the roof so you need to keep inside the exclusion zone so the edges of the panel don’t sit above the roof. Panels sticking above the roof are a feature to spoil the clear roof lines and detract from the roof , the pirimy design element of the house above the walls.

2. The wind loads are 25% higher withing 1200mm of the roof edge. This affects the roof panels and the support structural system. The installers have no technical knowlwdge of this and should not be engaged to play with the design. In may cases the person doing the design is a salesperson and not a designer so this is where the process goes wrong at the start. At the bottom edge if the support rails are positions on the first batten then the water running off the panel misses the gutter so the designer has to start with the first rail on the second batten to avoid this.

3. If you read the spec for the panels it gives the allowable overhang for the panel on the rail. This distance is based on a nominal wind not the wind on your site so the strength of the framing around the panel is limited to the maxiumum pressure/force the panel can take. And it is not based on the extra wind pressure at the edges of the roof.

4. Another aspect which is completely overlooked by just about everyone is the fixing of the support rails to the roof. The common practice is to replace the screws thru metal sheeting with longer screws to hold the rail on. These screws are to take the wind load of the sheeting into the battens. New screws should be used thru new crests on the sheeting to take the wind load from the panel into the batten.

Peter The Engineer

Great article thanks

A question I have relates for the rails.

If I need to fix the rails at one end in the exclusion zone, but the panel is mounted outside the exclusion zone, is that acceptable?

Thats OK becasue the wind load in the exclusion zone works by providing uplift on panels but does little to the rails.

The only problem with this is they the rails sticking out are very ugly.

Peter