Building-integrated photovoltaics (BIPV) company Umax Energy has been signed as the Australian master distributor for Shanghai-based module vendor GoodWe.

Under an agreement, Umax will also be GoodWe’s Australian BIPV tech support centre, offering system design, onsite installation guidance, project management, maintenance, and tech support.

The distribution and support for Goodwe inverters and Goodwe Batteries in Australia remains unchanged.

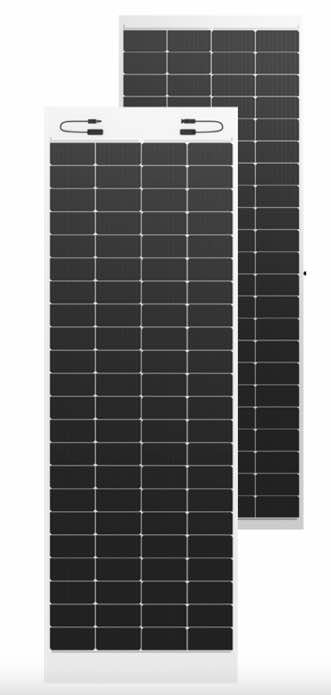

The GoodWe solar panel range Umax will carry includes the newly-launched Galaxy 335W panel, which the company said is designed for rooftops which can’t handle traditional PV and racking because they would suffer water damage, corrosion or leaks.

We couldn’t source a pic of a real installation – so here’s a render.

The Galaxy 335W has an IP67 rating, 12 year product warranty, 30 year performance warranty, and carries TüV and IEC certification for hail, wind, heat and fire protection.

It’s a frameless panel that weighs in at just 11kg, and is long and narrow, measuring 2,319mm × 777mm × 4mm. It was launched internationally in March and currently targets the European and Australian markets.

A 1.6mm layer of ultra-thin glass provides hail and high wind protection.

Suitable roof types for the Galaxy include single-ply, concrete and corrugated tin roofing, and the panels are glued or air welded to the roof.

The Galaxy series was launched in Australia at the recent Smart Energy Conference and Exhibition, where Umax and GoodWe signed their agreement.

GoodWe country manager Dean Williamson said in a statement:

“Traditional solar panels have limitations and potential dangers when utilised on commercial or low-load-bearing buildings.

“Our Galaxy series of solar panels provides the ideal solution for businesses looking to benefit from solar and having peace of mind that structural integrity remains, with no leaks or damage.”

RSS - Posts

RSS - Posts

If a glued on panel needs replacing, will this destroy the roof? How is roof damage avoided when removing the glue. What glue are they using?

Concrete roofing is listed. Does this include concrete tiles?

If it is glued to a corrugated iron roof how do you stop verman from nesting under them without interrupting the water shed

Interesting that their glass is just 1.6mm . Most all other manufacturers of glass glass panels are using 2mm to get past the hail test.

Glueing panels direct to substrates requires a certain cleaningness and surface preparation. How can they provide the quality control on such projects ? I would be very sceptical on the long term durability . And what is Air welding panels ?

Usually air welding melds two parts together that are made out of the same meltable material .Usually a hot air gun is used to glue waterproof membranes together for example.

Water will still go under the panels and the glue could hinder free water flow and drainage. It also will lead to lot of heat transferred direct to the roof substrate and into the building. Panels can get up 60 – 80 degree Celsius.

I have seen this temperatures on Enphase inverter readings. This will cause a lot of stress on the glue over time.

The whole thing sound like a bit of a not well thought through sales pitch. They don’t even have a project picture ?

I got a roof integrated system , 90 standard size panels , but we used the panels as roof finish instead of colourbond or roof tiles.

The warranty of the panel of 25 years is also longer than Colorbond ( 10 Years or Roof Tiles 20 – 25 etc etc.)

It was challenging to install but it works well .