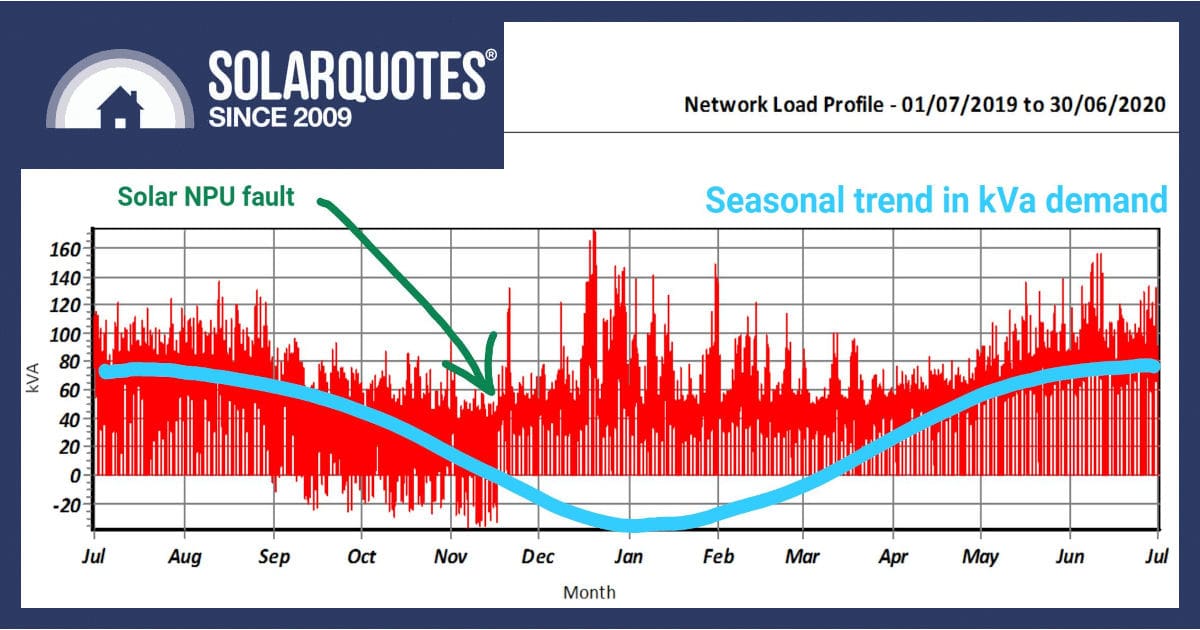

A year’s consumption data with a solar power system that stopped dead

Flicking through some photographs recently, I was reminded of a very expensive saga where thousands of dollars of electricity would have been saved with some free solar monitoring. Read on as we detail episode one of several expensive mistakes.

I sometimes lament I’ve spent many hours at nursing homes, and there’s one in particular I’ve visited too many times. I’m sure the quality of care is good, but the quality of the solar has proven undoubtedly questionable.

I’m proud I had nothing to do with its installation. However, I was the tradesman sent to diagnose faults and solve problems. I shouldn’t complain as it was a picturesque little town closer to my house than it was to the office, so often I would leave home and go straight there for a day’s… frustration.

Solar Is Simply Reliable, Isn’t It?

Conceptually, there isn’t much to go wrong with a solar system. Panels are solid-state, and the wiring is simple. There are a lot of electronics inside an inverter, but they’re generally very reliable, as there are hardly any moving parts.

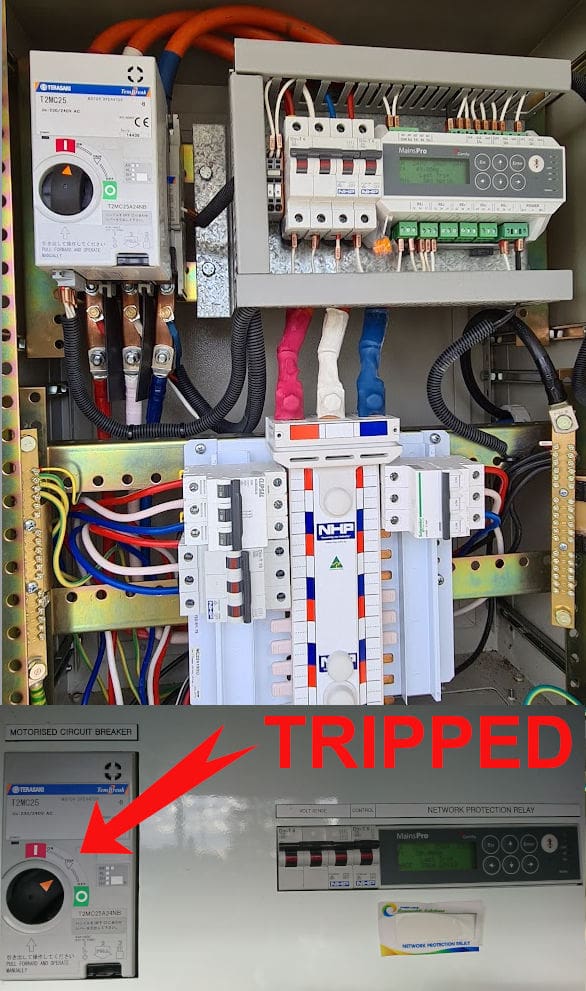

In this particular instance, though, it was a commercial-sized system requiring a network protection unit (NPU). The fatal flaw was inside the NPU, a motor-driven circuit breaker. This carried all the energy from the system and was designed to isolate everything if faults were detected by the controller.

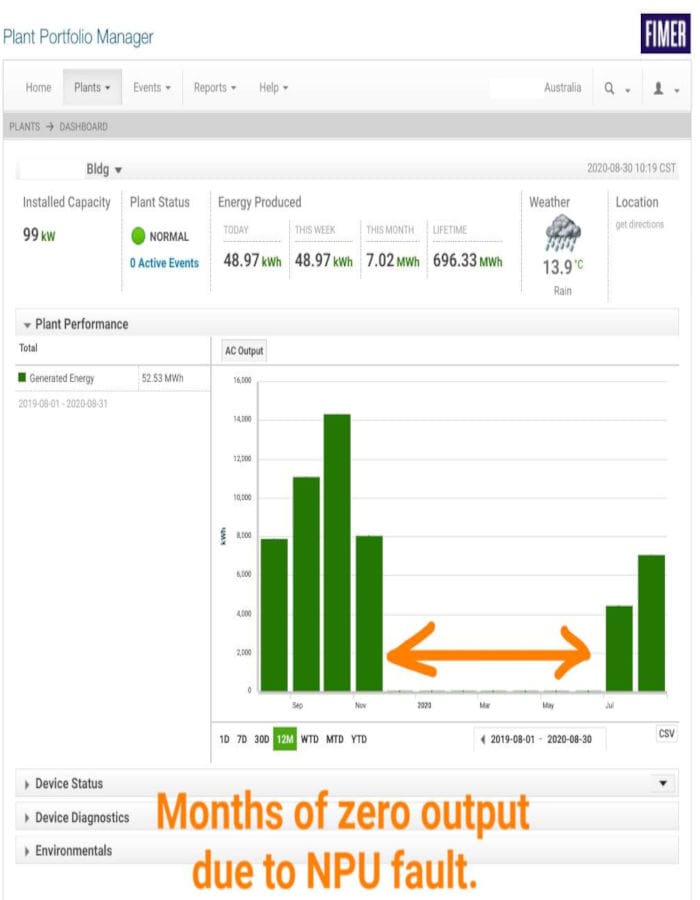

You could easily enough argue each of those green columns is worth $2000

When one small component failed inside the circuit breaker, the entire 100kW system went offline for months. Eventually, the accountants noticed the electricity bill looked suspiciously high, but not after they’d lost an entire summer’s worth of production.

The worst part? They’d lost ⅓ of the system 18 months earlier and didn’t notice this fault when it happened.

Something So Simple

Diagnosing this system was pretty straightforward. There was DC voltage coming off the roof but no AC voltage to the three 27kW inverters.

Working out the exact fault was following the bouncing ball using your multimeter.

The workings of an NPU aren’t complex, but this box can cost more than an inverter.

The failed trip mechanism from inside the circuit breaker was about half the size of a box of matches, but the complexity of the whole motor drive arrangement made me realise combining functions wasn’t a refinement.

Later model NPUs used a simple contactor and separate circuit breaker for reliability.

Another Month’s Delay

You can’t buy spares for Terasaki industrial equipment at your local Hammerbarn, so by the time we had it ordered, freighted and fitted, another month’s worth of production was wasted.

While it wasn’t ideal, all of the yield missing in the months prior would have been saved if the system was monitored and somebody had been charged with the responsibility of looking.

This trip mechanism, discoloured by heat from an internal solenoid, “fails safe” and switches the system off.

Automatic Alerts Are Priceless

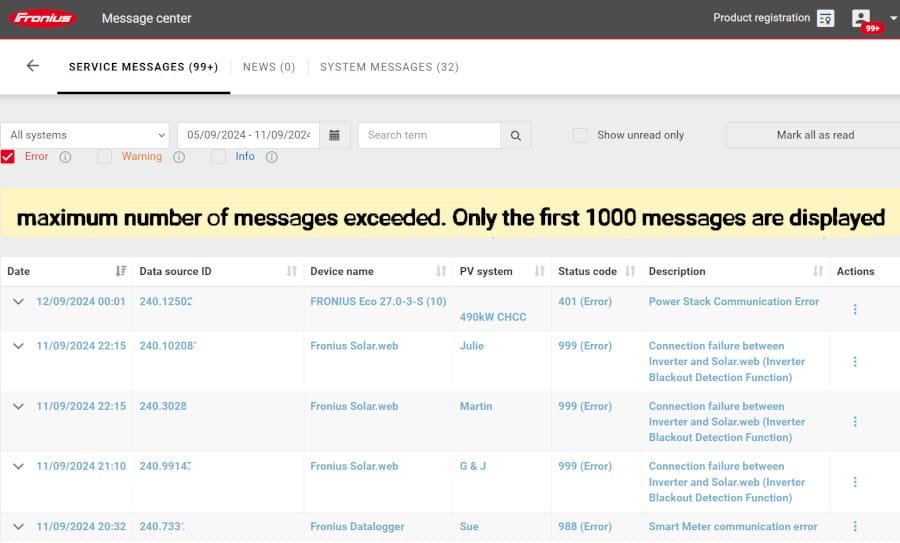

Solar inverters offer their own native monitoring, alerts, and email notifications you can customise to suit your needs.

Use them.

With Fronius Solar Web, I can program it to ignore overvoltage alarms from my uncle’s SWER line system1 because it’s the boy who cried wolf!

However, a “fault 457—zero production for 24 hours” comes straight to my primary email inbox.

Independent services like Solar Analytics can offer even more nuanced performance comparisons. I highly recommend them because they know what the weather is like in your district, even if they can’t detect a DC isolation or earth leakage error. For that kind of electrical fault, you still need the monitoring your inverter comes with.

Don’t Rely On Your Solar Retailer

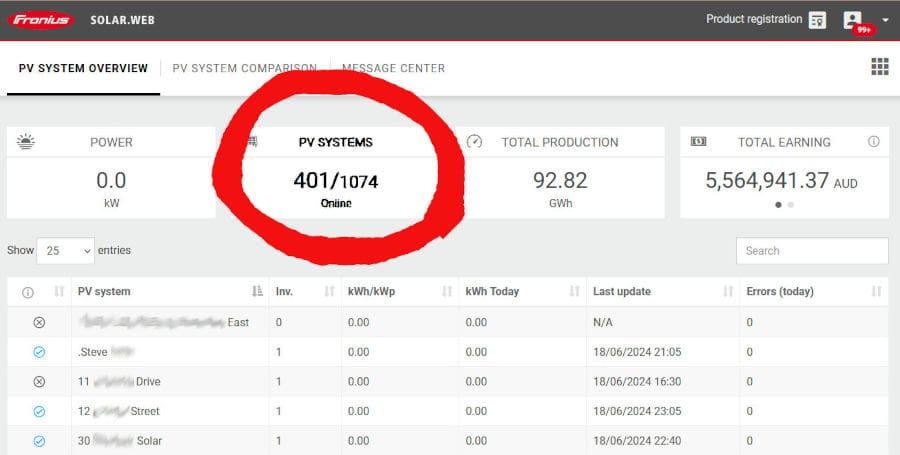

As we’ve mentioned before, solar retail companies have a fleet monitoring portal through which they can see your power system in action.

Rest assured that this is not a privacy concern because nobody at your solar company will bother to look at your system until you call them to ask.

Unimportant alerts clog the system, drowning out real problems in the noise. Either way, it’s best to monitor your own system.

When you raise a concern, remote monitoring will likely save a call-out fee. Your installer can log on and check the system remotely.

They may be able to allay fears, identify faults, or even bring appropriate parts with them to rectify problems with one visit.

Support Is Essential

A reliable installer will show you their monitoring and an interest in using it. What you don’t want is a sales company that goes broke and disappears with your warranty and your monitoring.

If your installer has wound up, or you just can’t stand the sight of them anymore, moving your system to another company isn’t hard. Manufacturers usually have a process listed on their website, which you can follow yourself without having to use technical support.

Less than 40% of this 1070-strong installer fleet is visible online

Make Sure You’re Connected

For my favourite nursing home, the WiFi access was troublesome. Finding the right signal, with enough strength, whitelisted by the IT security team and yet not being trusted with the password was infuriating.

Then, after half a day on the phone with tech support, it was finally proved that the comms card was no good. A replacement was ordered for another day. Thankfully, my iPad remembers passwords, so I didn’t have to deal with pensive staff while repeatedly entering all the network details.

Remember when software on CDs was a thing? This one survives in a forgotten storeroom of the dementia wing.

If you’ve changed your internet plan, router, retailer or NBN connection since your solar was done, there’s some chance that the inverter is no longer connected. Wi-fi works, but the best way to ensure reliable coverage is to use a data cable from your inverter straight into your internet router.

Ensure the emails coming from your monitoring platform (like Solar Web, iSolar cloud, PV Master, Aurora vision, SEMS) are getting through and not ending up in spam filters.

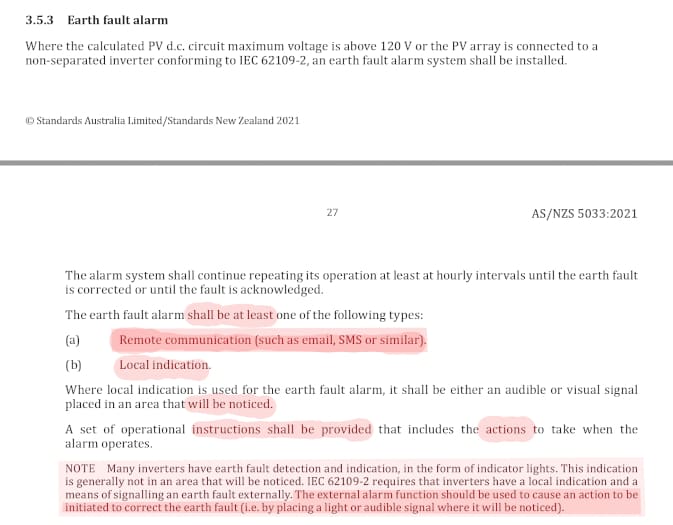

Unless your system has been installed with a strobe light or a buzzer, these email notifications are considered a legal responsibility so that you, the system operator, know if an earth fault has developed on your solar array.

As modern solar moves to flexible export, demand response and emergency backstop control by the networks, having a WiFi connection becomes an economic imperative, not just merely a safety rule.

Delinquency Costs Real Money

As electricity accounts are now being moved to demand charges, solar has a secondary benefit; reducing spikes in consumption. Generating energy behind the meter can avoid breaching demand thresholds, lowering your bills in a way not previously possible.

In our nursing home example, the operators lost months of solar kilowatt-hours, which ended up being thousands of dollars in electricity they imported instead.

I’d like to report they’ve learnt their lesson, but in our next update I’ll explain that just hasn’t happened. There are more tales of woe to come.

In the meantime, you should check that the app is on your phone, then check your own solar monitoring; it could save you thousands.

Footnotes

- a SWER (Single Wire Earth Return) line system is a rural electrical distribution method that often causes voltage irregularities ↩

RSS - Posts

RSS - Posts

Wow! Now I’ve seen it all! I get told off for watching everything from the PC and around the house, which supposedly is foolproof!

I can cope with that, but what I can not sort out is what is best, a high solar export price, with high import prices or a low export price with lower import prices? All the comparison algorithms show that there is almost no difference, as when I checked about 8 retailers, there was only a $75 difference per year.

And if you use the CATCH Power Control, you get Solar Analytics for free to give you all the monitoring and control you need.

Hi Stefan,

You’ll be pleased to know we have an article coming on Catch very soon.

Cheers

Yes effective system monitoring and control is critical.

But how effective really is monitoring [and control] systems, that share the customers wifi service for example, rather than having its own integrated standalone SIM service?

Lawrence Coomber

Damm, I feel sorry for muggles. This starkly reminds me what a luxury it is to be an engineer who designed his own off-grid system, so it has what I want. That includes a touch screen in the workshop, which I tap on the way through to the garage each day. With the GUImods update, I can tap on the DC-solar or AC-solar icon to drill down to second by second production rate of individual panel strings, seeing the change over the day as the sun swings to the west.

To avoid shifting my 70 year old derriere out of the sofa as I type this, I can click on an icon in my browser to bring up the same interface on my PC. (Just have to keep my feet on the coffee table out of line of sight to the monitor.) System monitoring *can* be made convenient.

If I want to check whether the 46 kWh battery was back up to 100% by 8:30 or 9 a.m., Another browser icon takes me to the VRM portal.

When charging the EV, using the 7.3 kW EVSE, it can be monitored and controlled by phone app or LAN login.

It is only a negligent mindset which allows an unnoticed quarter of a year’s production loss, I’d suggest. It is doubtless as you indicate, divided responsibility becomes irresponsibility. I tend to refer to such a culture as “managerism”, not management. (Engineers and managers come from different tribes, I think.)

Preach Erik 😉

Nailed it Erik.

Over the last 15 years of solar production, we’ve had various faults with our elderly solar system from broken solar panels (hotspot maybe?) to dead inverters and occasionally ground faults. It doesn’t take much to keep a reasonable eye on it all.

People need to do just a very basic check regularly – and then if not, to be honest I have little if any sympathy for them.

Our neighbours recently queried me about their bill. By going over previous bills, it turns out their inverter had been dead for nearly a year. All they had to do was look for that little green LED on the inverter, very clearly visible as they walk past it in the back yard, not to mention actually LOOKING at the bill for solar exports. Not exactly difficult!

What makes people so lazy- is it just pure ignorance or is it something else?

Yes David your second option is correct. It is something else!

And those “something else” people are the ones that mistakenly believe that modern energy plant systems should embody a high degree of semi intelligence in the form of reliable; and near failsafe, dual mode communications, including comprehensive monitoring and control smarts.

It seems this level of Smart System Comms design has been bypassed by nearly all well-known systems / power plant designers and manufacturers.

So my question back to your question David is now this: What makes ostensibly “smart systems designers” of mission critical functionality systems, seemingly so lazy on this topic – is it just pure ignorance or is it something else?

Lawrence Coomber

The Analytics options are quite expensive for a small residence with 6Kw panels and Tesla2. Is the Tesla app sufficient to monitor the system or would you still recommend the Annalytics device at around $1k?

Hi David,

I don’t own a Tesla personally so while I’ve fingered the app, I haven’t had a need to dirty my own device with it. However I’m well aware the Tesla app is one of the best, so if you can get a feel for how it works than it’s probably more than enough data.

I’m not sure if there’s a youtube tutorial on how to use it but if you can get another savvy user or installer to show you that might be a good place to start.

Solar Analytics now comes free with Catch Control but unless you have a specific need for the extra bells & whistles Catch offers, you might get a better return from a heat pump hot water.

Great advice in this article. I have found that Home Assistant makes for a good monitoring platform. If our Redback system goes offline or into a fault state I get an instant notification on my phone. Very handy!

“Don’t Rely On Your Solar Retailer”

You got that right !

We had 11.23kw of Trina panels (27), SolarEdge optimsied through 2 phases, Hub & Genesis inverters back in Nov last year.

So MANY stuff ups.

First, export limit not changed with SAPN (supplier), lost 2 weeks, then in order . . . wired up single phase, another few weeks lost, failed 6 month compatibility test going into winter, put onto fixed exports 1.5kw.

I put lower production down to winter sun, and the 2 huge lemon scented gums shading almost all the home.

Trees come down August, I immediately see capping at approx 2kwh, except where our production shoots up with appliances, then production matches, up to 5kw or so.

This 2kw was the approx 0.48 daily usage plus the 1.5 export limit.

I confirm with SAPN we were put on fixed exports back in May, when the test failed.

Onto the solar co, they and SolarEdge tried and failed numerous times to get the test through successfully, then it was realised SolarEdge had it configured as single phase in their software.

Corrected, and our production / exports shoots up triple or so.

Solar co said if I hadn’t brought this up, they would not have twigged to it, nor SolarEdge.

Not sure how the average person who thinks that solar is ‘set and forget’ would ever get the right output in such a similar case, I have been fastidious in monitoring all this on the SolarEdge app, AGL app and data, SAPN data, and know what to expect, what looks wrong, what needs further tweaking to get the lowest bills.

Good luck everybody !

Hi Les,

Glad to hear you have it sorted. 2 phase systems (and their country cousin the split phase arrangement) are easy to make a mess of, it’s something a lot of electricians only have a vague understanding of to be honest.

Thanks for the reminder, we need a blog on the subject.

I don’t have any monitoring on my system so my wife writes down my 3 reading on the meter which is my imported figure and 13 which is my exported reading and I enter those to a spread sheet on my computer so I have a daily reading of my imports and exports. I know by what the cloud cover is during the day and I have a pretty good idea of what my exports will be. I can go back over the years and compare my monthly imports and exports and surprisingly over the years they don’t vary much. I did know that the early part of summer my exports would be down because of a lack of sunny days. This in turn increases my imports. Either way my total power bill for each 12 month period has been about $150 . I will be interested to see how this 12 months goes with the latest price hikes

Hi Norm,

I know a bloke who’s been doing that with a notebook for 11+ years running and it’s been enough for him.

With a $150 annual bill I expect you’re on a rolled gold feed in tariff. However I still recommend a device like CatchControl to give you some real insight on consumption over the span of a day and night. When the tariff ends and you need to expand the system, you’ll already have a great data set to size what you need.

Hi Anthony,

My average daily imports over a 12 month period is 5.4 and my export is 12.7 and this has not changed since the system was installed 5 years ago. Amazing how close the figures are each month and year. Yes I do swap around a lot with my retailers hunting the best deals and because my import is low the peak rates don’t have a great effect on the bill but a good FiT does make a difference At the moment I get 19c for the first 3kwh per day and the drops back to 11c I am in Melbourne.

When my system was installed I was supposed to get 24 panels but they only turned up with 22. I was just recovering from a hip replacement and just agreed to it. In hindsight I should have said to them I would jump in my car and go and pick the extra 2 panels up but I didn’t . If I had the extra 2 panels fitted I believe my yearly power bill be close to zero. I figured if I wanted to get the extra 2 panels fitted it would cost over $1000 and with my annual bill of $150, it would take me 7 years just to get my money back.

Cheers Norm

Hi Norm,

I wouldn’t think adding two panels would be good value. Once you get an electrician to roll a truck & do a couple hours work they need to write off half a day & charge you for it. Buying two panels that match would also be an issue.

However if you have some other works done at the same time, like a hot water diverter for instance, it might make better sense.

It’s surprising to me how often “safety” devices like rooftop isolators and NPUs are responsible for breakdowns or even fires in solar systems. What’s crazy about this story is that replacement NPU is just as likely to fail.

And forewarned is forearmed on this topic:-

Solar PV Installations Monitoring & Control technology (it’s not just for system owners).

On-Grid Solar installations already have in place rules and regulations (via a written contract already in place) that networks and electricity retailers are entitled to enforce with customers (commonly referred to as the network service agreement fine print). These contracts are all encompassing ones formulated by the networks and electricity retailers without negotiation with the customer.

Importantly, these contracts involve customers agreeing to allow utilities to control the entire “system to grid interface” functionality of a customers solar /battery installation, and particularly system performance as it applies to grid feed in power and battery system charging and discharging logic controls.

As the number of grid connect systems increase, the more sophisticated will become the “system to grid interface” control algorithms, applied to customers systems.

Third party “approved by the network” monitoring and control systems (similar to the current network smart metering arrangements) will become mandated by networks to be fitted by customers to their systems (at the customers cost) in order to be eligible for an initial On-Grid connect approval. In the case of existing systems, the owners will be given a short period to retrofit a third party “approved by the network” monitoring and control system, to remain compliant as an On-Grid installation.

System owners who breach the connection contract T&C’s will be accountable I and penalised I expect.

We will be seeing more expansive moves from state legislators in this direction soon.

Lawrence Coomber