The Canberra Battery Test Centre’s third phase of testing is complete. In fact, all their testing is now finished. They have shut up shop and published their final report. But to help you benefit from their work, I’m going to go over the results of the last eight batteries they put through their paces. Next week, I’ll provide an overview of all 26 tested and offer advice on how to avoid buying a bad one. But for now, I’ll compress that advice into just two words…

Be careful!

Over the past six years, the Canberra Battery Test Centre has found poor reliability in systems tested. To minimize your odds of having home battery buyer remorse, here is my advice in three compressed bullet points:

- Make sure the battery is from a reliable manufacturer that is likely to still be around if and when you need to make a warranty claim.

- Buy from a good installer who is happy to return as many times as it takes to fix any problems that occur.

- Make sure you know how to use the monitoring to determine how much the battery capacity has degraded over time.

This won’t guarantee you’ll have a problem-free installation, but at least any problems that do occur should be reasonably rapidly rectified. Note that none of the points above are likely to apply if you buy the cheapest battery available.

This article will concentrate on how well the latest eight batteries from the Test Centre’s third round of testing performed. I’ll give details, but I can compress it all into one word right now, and that’s…

Awful!

Not one was problem-free. The only good thing I can say is the average results are a little better than for the 18 batteries tested in earlier phases. But nothing has performed as well as the Sony Fortelion, which was among the very first tested and was still going strong at the end of testing after the equivalent of 10 years of daily cycling.

Test Centre Reports

The Phase 3 battery results are included in the Canberra Battery Test Centre’s final report:

But if you want the full story, you’re also going to have to go through reports 11, 10, and 9. But that’s all. If you go back any further in time, it will result in Phase 3 battery testing not yet existing.

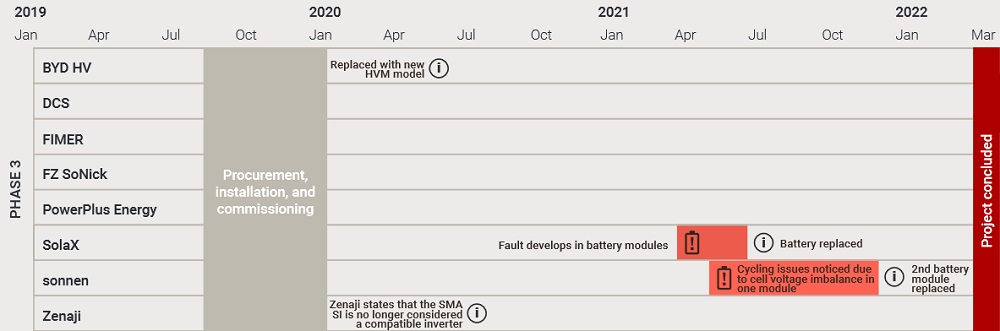

Phase 3 Batteries

Phase 3 testing began in January 2020 and continued until March this year, giving a total testing period of 2 years and 3 months. The eight batteries tested were…

- BYD HVM 11.0

- DCS PV 10.0W

- Fimer React 2

- FZ SoNick

- PowerPlus Energy LiFe Premium

- SolaX Triple Power

- SonnenBatterie

- Zenaji Aeon

The table below is from the final report and shows some of the problems the batteries experienced:

Accelerated Testing

Two and a quarter years of testing isn’t long, given most home batteries are warranties are for 10 years and — fingers crossed — they’ll hopefully last 15+ years in practice. To get a more realistic picture of how they will perform long term, the Canberra Battery Test Centre used accelerated testing. This involved charging and discharging the batteries roughly three times more often than in normal household use.

The majority were fully charged and then discharged of all their usable energy three times per day. Each repetition is called a “full cycle” or just “cycle” for short. Home batteries are normally cycled an average of less than once per day, but special circumstances or joining a Virtual Power Plant (VPP) can increase this. For convenience, it’s generally assumed a home battery will be fully cycled an average of once per day. This means one will be cycled 3,652 times by the end of a 10 year warranty.

This testing isn’t identical to daily cycling as the batteries are charged and discharged faster than they would be in actual use, and this may increase battery capacity loss. But it is the best way to get rapid results on reliability and capacity loss. In the time available for phase-three testing, it would have been technically possible for batteries to have received the equivalent of 4.8 years of daily cycling but, because of various problems, only one managed this much testing.

Sample Size Of 1

Only one of each battery was tested. Because of this small sample size, we can’t reach any solid conclusions on how reliable individual batteries are. To be confident, multiple systems would have to be tested. The test results are evidence of the batteries’ reliability but not conclusive evidence.

Good Communication Is Key

Home battery systems normally have at least one battery module. For lithium batteries, these are rectangular metal boxes containing lithium cells. For other chemistries, there can be other weird stuff in there. For example, a car battery is stuffed full of lead and acid.

Modern home battery modules have electronics in them that function as the Battery Management System (BMS). Most home battery systems have a communications link from this to the inverter. This allows the BMS to control the charging and discharging of the module – overriding the battery inverter to protect the battery cells when necessary. Because the BMS is made for the specific module, it can optimize its performance1.

But there are also home battery systems that don’t have a link, which means the inverter controls the battery without any feedback from the BMS2. This is a simpler design, but without a communications link, the inverter can’t fine-tune charging and discharging as effectively. While this setup can work well, in testing it has often resulted in batteries being unable to supply the amount of usable energy manufacturers claim they are capable of.

Because of frequent problems, I suspect battery systems without communication links will be replaced in the market by those with them.

Different Kinds Of Faults

I’ve divided issues that arose in battery testing into five categories:

- Stealth problems: These are problems the Battery Test Centre noticed, but a typical homeowner could easily overlook for an extended time — until they become more serious.

- Major Problems: Major problems are anything that prevents the battery from functioning at or close to the level it should.

- Replacement parts: How many times were components replaced?

- Replacement batteries: How many times was the entire battery replaced?

- Capacity retention: An estimate of remaining battery capacity at the end of testing.

Note a stealth problem can become a major problem if it requires repairs or a replacement battery. Unfortunately, there will be many owners whose systems are suffering from stealth problems right now. Almost all modern battery systems are monitored online, which makes the number of times the Canberra Battery Test Centre was the first to discover a problem a concern. It makes online battery monitoring seem a bit bloody useless for consumers.

BYD HVM 11.0

BYD is a giant Chinese battery manufacturer. Testing began on an older model of home battery. But in June 2020, after several months of testing, BYD — quite sensibly — replaced it with a newer model as the old one was discontinued.

Despite coming from a company with plenty of experience producing battery systems, the BYD HMV 11.0 suffered two major breakdowns. In the month after it was installed, the battery refused to turn back on after a power outage. This was a serious problem because blackouts can happen to households at any time. BYD was able to help the Test Centre get it working again, but for a home battery, this fault would have required the installer to return to the premises.

The month after that, the battery developed a software fault and stopped working. BYD, again, helped get it going, but this problem took over two months to fix.

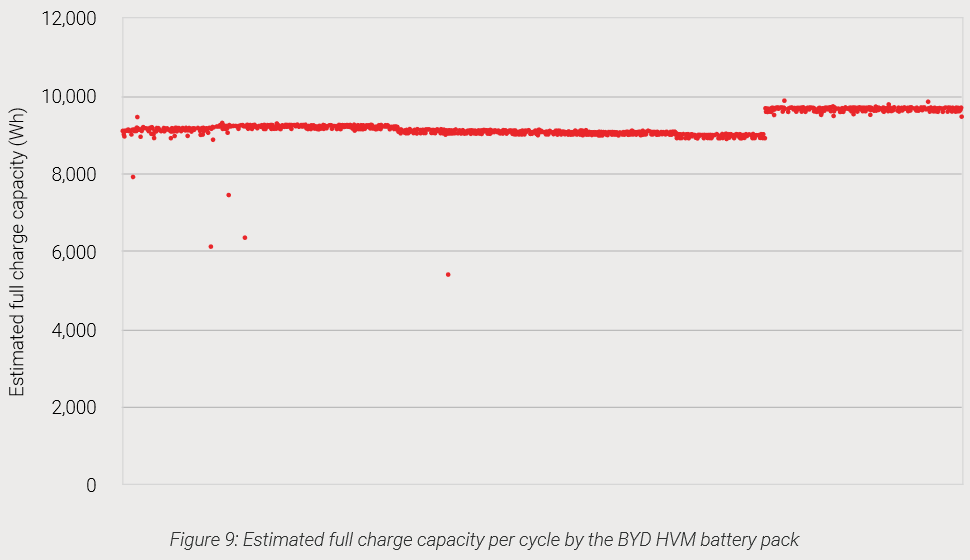

The capacity retention of the BYD B-Box HVM appears perfect, with no measurable decline in output after around 1,180 cycles, which represents around 3.2 years of daily cycling. After a firmware update3 in October 2021, the amount of usable battery capacity increased:

Note that even after the update, at just under 10 kilowatt-hours, it’s supplying less than the 11 kilowatt-hours usable energy storage the battery can provide according to its datasheet. So while it shows no sign of capacity deterioration, it may be occurring behind the scenes, and will only become apparent once it has progressed far enough.

I’m tempted to include only providing 90% of the usable energy it should as a major problem, but the performance of home batteries overall has been so poor this is actually a good result on average, so I’ll grade on a curve and let it pass.

- Stealth problems: 0

- Major Problems: 2

- Replacement parts: 0

- Replacement batteries: 0 (It was replaced with a newer model, but not because of a fault.)

- Capacity retention: No sign of capacity loss after the equivalent of 3.2 years of daily cycling.

DCS PV 10.0W

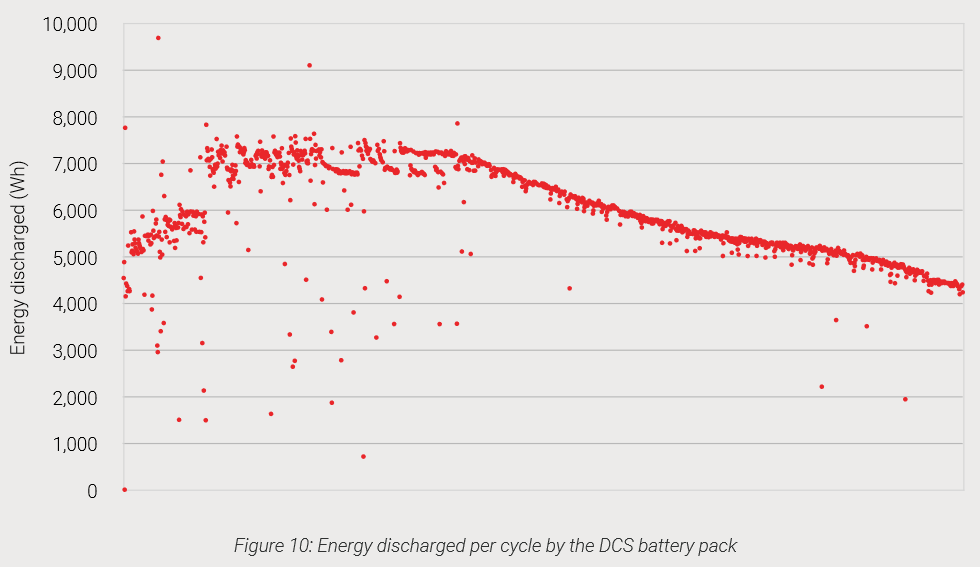

The DCS PV 10.0W4 battery system is made by Deep Cycle Systems in Queensland with imported batteries. It was installed with an SMA Sunny Island Inverter and doesn’t have a communication link from the Battery Management System to the inverter.

Unfortunately, this was one of the many cases where this arrangement didn’t work well and on average the battery supplied much less energy than DCS said it would. The Test Centre was able to improve this by cycling it over 8 hours, rather than the 6 used for the other lithium batteries, but energy output still averaged under 75% of what it should have been.

The battery has suffered a large decline in capacity. It was estimated to be at 57% of its original capacity after around 1,100 cycles or the equivalent of three years of daily cycling. At that rate, I suspect it wouldn’t have been long before the battery became unusable. DCS requested it be returned to them so they can examine it.

- Stealth problems: 0

- Major Problems: 2

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Atrocious at only 57% of original capacity after the equivalent of 3 years of daily cycling.

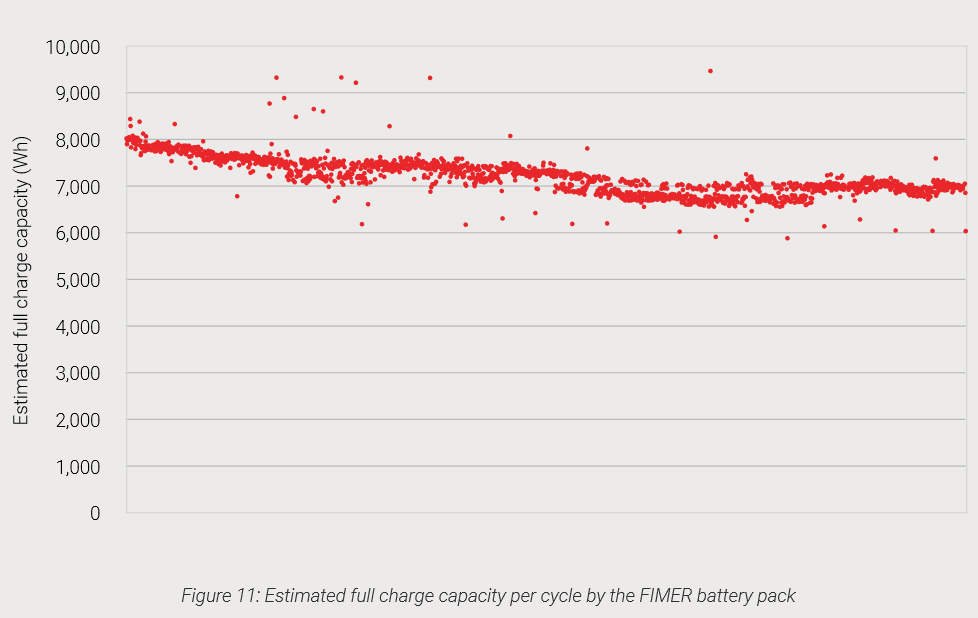

Fimer React 2

Fimer is a European company with headquarters in Milano. This is Italy’s 2nd largest city, and its population of 1.3 million would make it Europe’s Adelaide, except the coffee isn’t as good.

Fimer took over the ABB inverter company, so their battery is sometimes referred to as an ABB Fimer battery. The Fimer React 2 is a lithium energy storage system with its own inverter that can be AC or DC coupled. The one tested was DC coupled and had two 4 kilowatt-hour battery modules with a total of 7.6 kilowatt-hours of usable storage.

The battery had no problems until just prior to the end of testing when the Test Centre discovered one of the two battery modules had developed a fault, but at that point it didn’t stop it functioning. Fimer has said they are investigating the cause of the problem. This was a stealth fault, as no normal household would have noticed the problem unless it became a lot worse.

After around 1,740 cycles — the equivalent of 4.8 years of daily cycling — the batteries were estimated to have 86% of their original capacity. At this rate, they will have around 71% of their original capacity after 10 years of daily cycling. This is well above the minimum of 60% it is warranted for.

- Stealth problems: 1

- Major Problems: 0

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Acceptable and on track to be well above the 60% minimum capacity it’s warranty promises.

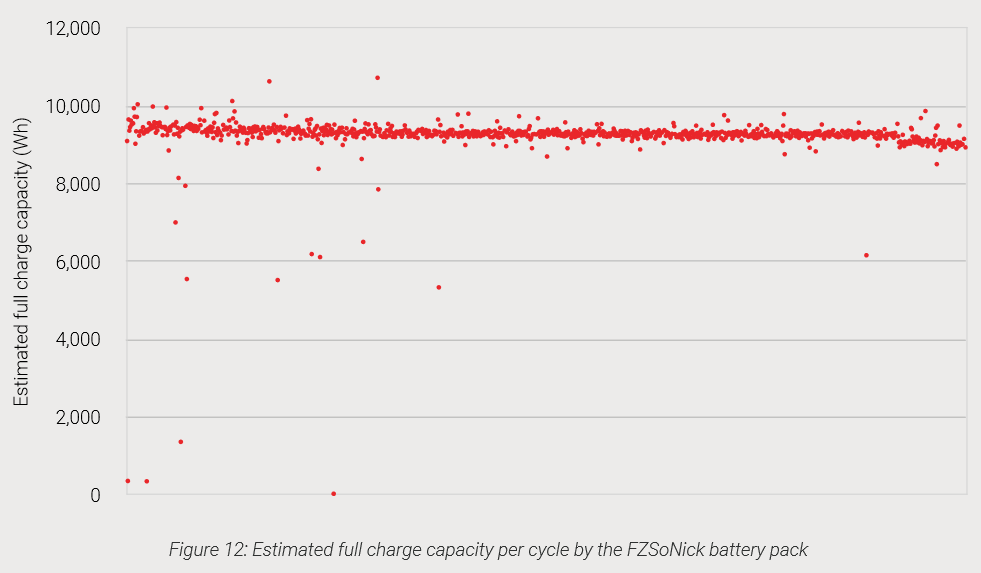

FZ SoNick

The FZ SoNick battery stands out for two reasons:

- It’s really hard to pronounce

- It’s the only sodium nickel chloride battery tested

This molten salt battery operates at around 250 degrees. But if you’re thinking about getting one and making it serve double duty as a barbecue hotplate, the bad news is the outer casing is only a couple of degrees above room temperature. Despite remaining safe during operation, this battery chemistry is normally not used in homes. The manufacturer says they’re for industrial use, and I don’t think they’ll ever be widely used for residential energy storage.

The FZ SoNick battery used a Victron inverter, and when first installed it did not have a communications link between the Battery Management System and the inverter. But with help from the Australian FZ SoNick supplier, the Test Centre was able to set one up. This was probably a good idea, as the other three batteries in this phase of testing without communication links suffered problems.

It had a fault where the Test Centre noticed it wasn’t fully charging and only reaching around 80%. It was a stealth problem as it’s not the sort of thing the average homeowner is likely to notice. After they alerted the manufacturer, it was fixed online.

Because of its unique chemistry, it could not be cycled as rapidly as the lithium batteries and only racked up around 880 cycles. That’s the equivalent of 2.4 years of daily cycling, but because of its low power output, it’s unlikely to be fully cycled an average of once per day in most applications. At the end of testing, it had approximately 94% of its battery capacity remaining. If this rate of capacity loss was maintained, it would be on track to be at around 75% of its original capacity after 10 years.

I have listed the battery not fully charging as a Stealth Problem, as a typical household would be unlikely to notice it. Because I consider only charging 80% a major departure from normal operation, I’ve also included it as a major problem. On the bright side, it was resolved in a month, which is far better than some battery repair response times.

- Stealth problems: 1

- Major Problems: 1

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Acceptable as it’s on track to be at 75% after 10 years of daily cycling.

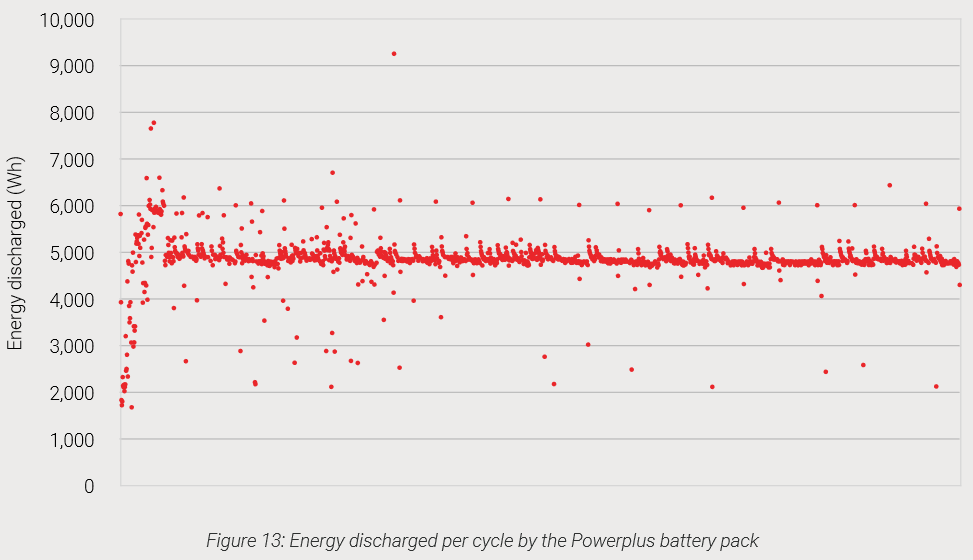

PowerPlus Energy LiFe Premium

The LiFe Premium from PowerPlus Energy is another battery without a communications link between the Battery Management System and the SMA Sunny Island Inverter it was paired with. The battery’s warranty requires it not to be discharged by more than 80%, but in practice it was difficult to determine its actual state of charge. Three modules with a total storage capacity of 9.9 kilowatt-hours were used. With a maximum 80% depth of discharge, that technically gave 7.9 kilowatt-hours of usable storage – but it normally provided under 5 kilowatt-hours per cycle.

After around 1,030 cycles, its capacity was estimated at 95%. If correct, that means it would be on track to be at around 82% after 10 years of daily cycling.

But despite this capacity, in practice the battery inverter could only extract about 60% of the battery’s usable energy per cycle.

While the battery supplied stored energy, it did not operate at close to the level it should have, so I count that as a major breakdown.

- Stealth problems: 0

- Major Breakdowns: 1

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Acceptable in that it appears to have over the 60% minimum capacity it’s warranted for after 10 years of daily cycling, notwithstanding battery control issues.

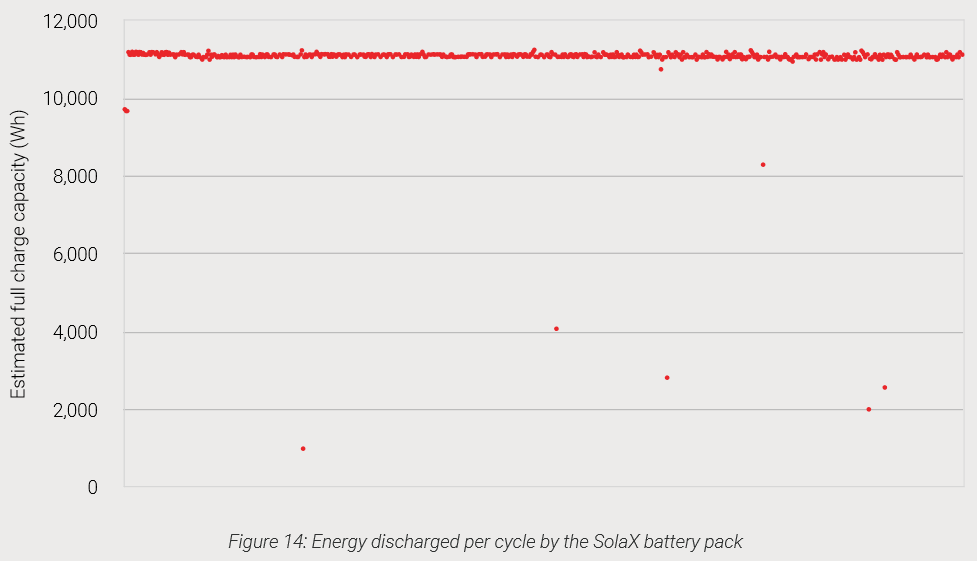

SolaX Triple Power

The SolaX Triple Power battery system worked well for the first year of testing, but then its ability to charge and discharge began to decline. SolaX attempted to fix it over the internet but concluded the battery needed to be replaced.

It performed well after that, but the new battery was only tested for around 600 cycles before testing ended. It had around 98% of its original capacity at this point. If this was maintained, it would retain 88% of its original capacity after 10 years of daily cycling, but the testing period of the replacement battery was too short to be confident the low rate of capacity loss would be retained.

Because a typical homeowner may not have noticed the problem that led to the SolaX Triple Power being replaced, I have called it a stealth problem. As it required the entire battery to be replaced, it’s also a major problem.

- Stealth problems: 1

- Major Problems: 1

- Replacement parts: 0

- Replacement batteries: 1

- Capacity retention: Good for the 1.6 years of simulated daily cycling that was performed, but the testing period was too short for confidence.

SonnenBatterie

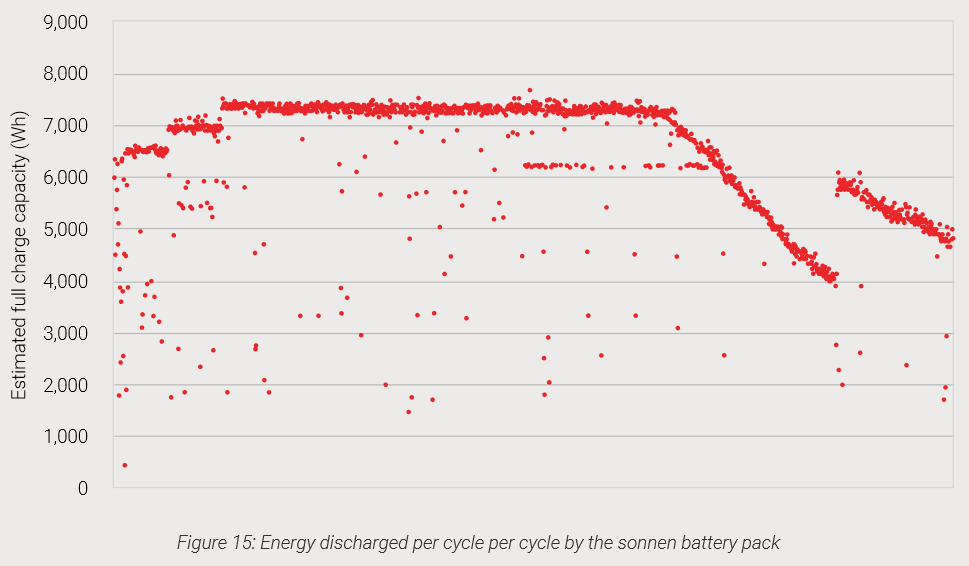

Sonnen’s SonnenBatteries are made in Europe using batteries produced in China. After some initial difficulties with its installation, the SonnenBatterie functioned well for 14 months of testing before developing a fault that caused its usable capacity to drop. The graph of its first 20 months of testing makes it clear when it happened:

Sonnen attempted to fix it online and then replaced one of its four battery modules. Six months later, they replaced a second battery module because it wasn’t operating as well as it should have.

The battery showed no signs of capacity deterioration in the 800+ cycles before the fault occurred or in the 160 cycles after half its battery modules were replaced. As its warranty allows the battery to be cycled 10,000 times while still retaining 80% of its original capacity, I am not surprised there was no noticeable loss of capacity.

- Stealth problems: 1

- Major problems: 1

- Breakdowns: 0

- Replacement parts: 2

- Replacement batteries: 0

- Capacity retention: Excellent over the limited number of testing cycles given.

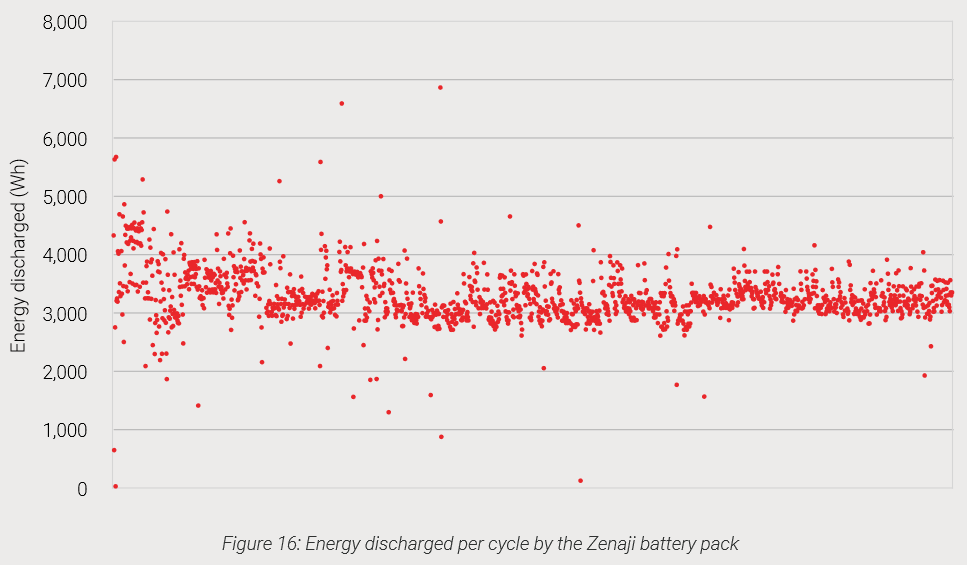

Zenaji Aeon

The Zenaji Aeon battery is another unit without a closed-loop communication link between the battery module’s Battery Management System and the SMA Sunny Island inverter controlling it. As with many other batteries, this has resulted in problems; in this case, they were pretty disastrous. From the start, the Battery Test Centre could not accurately measure the amount of charge stored and it only provided around one-third of the energy per cycle it should have.

Six months after the installation of the battery, Zenaji removed the SMA Sunny Island from its list of compatible inverters. In their 10th report, the Test Centre said testing would continue with the SMA Sunny Island inverter until Zenaji replaced it with a Victron inverter, but this never occurred and the SMA Sunny Island was used until the end of testing. No mention of a replacement Victron inverter was made in subsequent reports.

Because accurate measurements could not be taken, no estimate of battery capacity was possible.

While it’s possible the battery may have worked acceptably with a different inverter, the poor performance that resulted from using an inverter Zenaji said was compatible was still definitely a major problem.

- Stealth problems: 0

- Major Problems: 1

- Replacement parts: 0

- Replacement batteries: 0

- Capacity retention: Unknowable under given testing conditions.

Phase 3 Results — Best To Worst

Here is a sarcastic list of all the Phase 3 batteries that operated without a problem from their first day until the end of testing:

No, I haven’t accidentally left out the problem-free battery systems. There weren’t any. The one that came closest was the Fimer React 2, which didn’t develop a fault until just before the end of testing. It also had an acceptable capacity loss. While worse than two other Phase 3 batteries, it was on track to be at around 71% of its original capacity after the equivalent of 10 years of daily cycling, which is well above the minimum of 60% allowed by its warranty.

Below I’ve ranked the eight Phase 3 batteries from best to worse, in my opinion. This is only based on how well they performed in testing and does not mean one higher on the list is definitely better than one below it. It’s also subjective. In my opinion, a battery system that underperforms for years is worse than one that breaks down but is soon repaired or replaced. Of course, you may disagree. In this case, please feel to cut your screen up with scissors and rearrange the list as you see fit5.

From best to worse — in testing — the battery systems were:

- Fimer React 2 — One fault towards the end of testing. Acceptable capacity loss.

- FZ SoNick — 1 major problem was fixed in around one month, but it was a stealth problem typical owners may not have noticed for some time. Acceptable capacity loss.

- BYD HVM 11.0 — The battery broke down twice. No measured capacity loss during the period tested.

- SonnenBatterie — 2 out of 4 battery modules had to be replaced. No measured capacity loss.

- SolaX Triple Power — It broke down, and the entire battery had to be replaced. Capacity loss appeared minor, but not enough testing was done to be confident.

- PowerPlus Energy LiFe Premium — Only provided around 60% as much usable energy as claimed. Capacity loss appeared acceptable.

- Zenaji Aeon — Only provided around one-third as much energy per cycle as it should have. Capacity loss could not be determined.

- DCS PV 10.0W — Usable energy was, at best, around 75% what it should have been. Severe capacity loss.

The bottom three on the list were the only units without communication links between the Battery Management Systems and inverters. This result, as well as the results of previous phases of battery testing, makes me think communication links will become standard.

A Conclusion

While there is only so much that can be concluded from testing one system, it is possible to conclude the majority of home batteries installed two and a half years ago had major reliability issues. Next week I will give an overview of the Canberra Battery Test Centre’s entire six years of operation, along with some basic advice on how to avoid buying a bad battery.

Footnotes

- This configuration is also known as ‘closed-loop control’. The link from the BMS to the inverter closes the feedback loop, so the inverter can fine tune its output based on one or more real-time battery variables. ↩

- Also known as ‘open-loop control’. ↩

- A firmware update is a type of software update that affects the operating system. It was done online without any physical contact or new hardware involved. ↩

- Normally I would make fun of the fact that the “W” at the end of DCS PV 10.0W makes it look like it’s a 10 watt battery, but because I’ve matured as an individual, I’m going to restrain myself and draw zero attention to it. ↩

- For safety reasons, you should put your screen under water before cutting it. ↩

RSS - Posts

RSS - Posts

Oh, great!

So, these represent the types of technologies we are relying upon to allow the world to decarbonise.

Maybe now time to look for a ‘Plan B’…!

RoFL. Your thinking parallels mine.

We really are going back to windmills, sunshine, and unicorn farts!

Anyone know where I can get horse riding lessons? :-|)

George Kaplan,

“Anyone know where I can get horse riding lessons? :-|)”

Have you room for one? I’d suggest it’s probably cheaper (and less space needed) to have an e-bike. ?

You might also consider where your food will come from in future. Per the Australian Security Leaders Climate Group’s June 28 report titled Food Fight“:

https://www.aslcg.org/reports/

Meanwhile, Australia imports 40% of its diesel, the premier transport fuel enabling our critical supply chains, from Taiwan, South Korea and Japan, as China’s military “exercises” around Taiwan practice with mobilising fighter planes, helicopters and even warships, aiming to simulate a blockade of Taiwan and include practising an “attack on targets at sea”, according to state news agency Xinhua.

https://twitter.com/crudeoilpeak/status/1556467064441049088

It strikes me that the three cycles a day accelerated testing regime would put an enormous strain on the equipment and that to withstand it, they would need to be specifically designed for that kind of treatment, in terms of both component and heat resilience…which sort of defeats the purpose of the testing regime.

The only realistic test is realistic use, which of course is going to take 10 years, which also defeats the purpose of the test, which is to give reliability results now……

I cannot see any way out of this conundrum, other than perhaps to look at car batteries that have been around for a bit longer. But of course, those older chemistries do not represent the latest generation technology, which defeats the purpose of the test.

Ho hum. I am not able to make a constructive suggestion here, other than to take the test regime with something of a grain of salt.

The takeaway is that over time, good quality product delivered by reputable suppliers to reliable installers, none of whom come cheap, is the way forward, if battery ownership is a must, for whatever reason.

More, if one intends to buy an EV, a separate home battery is overkill and increased PV is on the money, dribbling in current through a 10 amp plug which is nice-‘n-easy-does-it that the battery is sure to appreciate by giving longer life……

Where possible, the batteries were charged over 3 hours and discharged over three hours and given 2 hours rest between these full cycles. That’s a lot of work compared to normal home use, but it was permitted by manufacturers. The results do need to be taken with some grains of salt, but they were used with spec.

Some batteries were charged and discharged more slowly in compliance with manufacturers’ requirements.

Christopher Eastman-Nagle,

“It strikes me that the three cycles a day accelerated testing regime would put an enormous strain on the equipment and that to withstand it…”

I’d suggest the purpose of the testing regime is to accelerate the discovery of any weaknesses in the battery systems under test over a shorter time period. Waiting around 10+ years to get a definitive answer is not helpful when answers are needed much sooner, as you alluded to with:

“The only realistic test is realistic use, which of course is going to take 10 years, which also defeats the purpose of the test, which is to give reliability results now……”

Meanwhile, knowledge and technologies would have likely progressed.

“…to take the test regime with something of a grain of salt.”

Yep, it’s one indicator among many others.

It seems to me that home BESS technologies are still maturing, so unless you wish to be an early adopter/experimenter (with the dosh or finance) then I’d suggest waiting a bit longer for some further improvements.

Meanwhile, proposals for utility-scale BESSs are getting bigger, like:

* Eraring BESS (700 MW / 2,800 MWh);

* Waratah Super BESS (700 MW / 1,400 MWh);

* Liddell BESS (500 MW / 2,000 MWh);

* Wallerawang BESS (500 MW / 1,000 MWh).

https://reneweconomy.com.au/big-battery-storage-map-of-australia/

I’m far more concerned about Australia’s worsening liquid fuel security, that will consequently affect our food security, unless we rapidly reduce our petroleum dependency within this decade – see my earlier comments. Unfortunately, it seems to me many people cannot see the escalating risks or are in denial.

https://www.solarquotes.com.au/blog/fuel-efficiency-standards-mb2539/#comment-1479477

These test appear very reasonable. I have been in the Equipment test business for years including designing test equipment. Yes it is sad that so many are so bad

On a sample size of one:

1) it’s better than zero;

2) the chance of any individual purchasing a given battery is the same as that which applies to the Testing Centre;

3) therefore the battery i purchase could well be the poor performer and provide headaches rather than Watts;

4) it seems that there is some way to go before this technology is ready at a reasonable price;

5) thanks for the excellent summary.

If these batteries are showing such flaws, what faults will community batteries, which aren’t being tested, show?

For that matter, how do EVs compare in terms of battery unreliability?

Seems like either the tech is far less developed and mature than I realised, or manufacturing standards are very loose.

Modern Lion EV batteries can easily do 800 full cycles. In a 400km range EV that would mean 320,000km with one battery.

Remember how the home batteries in the Canberra test were cycled more than 1600 times over the test period. In ten years a home battery would need to be able to cycle 3650 times. That is way more cycles than the car battery after 320,000km. 400,000km/400km = 1000 cycles).

Estimated EV battery longevity after 1000 cycles in a 400 km range EV:

27 years when driving 15,000km a year or 400,000km total.

19.2 years when driving 20,800km a year or 400,000km total. 400km/week.

In reality these numbers would be lower depending on a range of factors, but EV batteries will still last a very long time. There’s just not enough data available to judge for long time frames.

Factors for battery longevity include:

– how is the battery charged/discharged – always 0% t 100% or 20% to 80% as recommended.

– if charged to 100%, was the car used immediately after that or left fully charged which is detrimental to battery life

– how many times was the battery fast charged

– how good is the battery management system in keeping the battery in tightly controlled parameters

– do you live in a cold or hot country

– to you flog the car at every light? The battery is stressed more in this scenario.

– what is the battery chemistry

– how big is the battery – bigger = less cycling

These are all things that EV buyers have to learn about and get used to, almost like knowing when a service in an ICE car is necessary and that low oil and low radiator water is not good, as well as driving sporty all the time.

Thanks for this summary. I have friends who are thinking of investing in a battery because they are now so cheap. I will offer them the opinion that they wait a few more years.

From your observations how do you think a flow battery would compare on price and reliability?

I am trying to understand how these batteries can appear to be so reliable when used in a farm of hundreds or thousands of batteries. Do they just have a high fraction of redundancy and their own staff to provide rapid repairs?

Cheers

Flow batteries were tested in previous rounds.

The short answer is: Don’t get a flow battery.

I assume his test was commissioned by the govt. if so can we expect the disastrous results for consumers to be commented on in the press together with some suitable advice for anyone contemplating their costly installation.

If we can get the press away from their regular gotcha moment chasing to perhaps interview the minister concerned to perhaps issue a caution to those of limited and fixed means but with good intentions, that these are nir not the financial nirvana they are made out to be instead just a feelgood, at least until there is a considerable improvement in battery chemistry and just put more panels on the roof till then. I hope vehicle batteries fare better but I doubt it.

Re Zenaji: I am a fan customer of this battery. I had 4 of their early (Pre-Aeon) batteries that were replaced under warranty. (Early ones had issues with the CBs tripping, although I never had that problem with mine).

I now have 6 Aeon batteries hooked to 2 Victron Multiplus 2 inverters (on a rural 2 phase supply). I run the batteries down to under 10% most nights. I charge to 30% at 1am to 3am for the breakfast draw, then the PV charges them by about 10am. These Australian made Lithium titanate batteries have a 20 yr guarantee, or 20,000 cycles. They are more expensive than Lithium Ion, but should outlast 2 Lithium Ion batteries. (They may well outlast me!).

I do not charge my EV from the batteries: the EV circuit bypasses the batteries. (At Energy Next there were companies promoting charging evs off your batteries, but I feel the efficiencies are too low, which increases the cost. Also, fyi, I do not charge (my Kona) at less than 10A/240v due to losses.

Zenaji batteries, I feel are a good option. They would work well in an off-grid situation too. (because they can be run to practically zero).

forgot to add that using the Victron + DC Energy meter (Victron current shunt) gives accurate measure of the state of charge. I would love to have access to the battery information from the BMS, but it is not really necessary I feel.

The results are concerning, but congratulations to all involved in the testing – it has provided clear, evidence based results for all to see – suppliers and potential customers alike. A thousand times better than sales spin. We have a way to go. Good science and engineering will get us to where we need to be. Bagging out the strivers from the sidelines is cheap politics. Let’s get on with it.

You hope…

Batteries have been around since 1800 (Volta), although storage batteries not until 1859 (Gaston Plante – Lead-Acid). NiCd’s came along about 40 years later, and NiMH about 90 years after that. A long, long, slow development process.

First experiments started in lithium began in 1912, which Sony commercialised (Li-ion) in 1991.

So – storage batteries have been under development for about 160 years.

Li-ion for about 30 years – at an EXTREMELY higher rate of R&D.

What worries me the most, is that we have proponents who plan ONLY to ‘hitch our Wagon’ to batteries in order to address Global Warming – and we only have ~ 8 years of development time left to meet our 1st hurdle (2030).

Must all be betting men – with ‘systems’ to ensure they win every entry in Lotto…!

This is not about politics – it is about the survival of the human race!

Yes, by all means let’s continue trying to solve battery problems – but for my money, I feel we also need a Plan B, ‘just-in-case’ all our or our best efforts fall by the wayside (or, ongoing premature failures and replacements lead to horrendously high electricity costs, and possible loss of grid stability). There is also the issue of materials availability – should the overbuild become necessarily excessive.

I wouldn’t buy a battery unless it’s a Tesla to be honest. I haven’t had any issues with mine yet, fingers crossed I don’t over it’s 15 year warranty.

Why isn’t it included in the testing?

This report focused on their Phase 3 testing which didn’t include a Powerwall 2. But I’m writing another report which will cover every battery they tested and that will have information on their Powerwall 2 results.

Hint – if you read Ron’s other reports on the Battery test centre, Tesla did not fare well at all. Once again – accelerated testing on large capacity multi cell batteries is not a valid real world paradigm. It’s an indication at best.

Our shared dreams of a future energy utopia seem, alas, to be perhaps morphing into something far more dystopian. It’s probably too early yet though to commission Alice Cooper to write a new song titled ‘Welcome to My Energymare” to be used as the sound-track in yet another version of “Mad Max”

See: https://en.wikipedia.org/wiki/Alice_Cooper#/media/File:Alice_Cooper_band_Live_in_London_2012-10-28_(close-up).jpg

Overall, I pretty much agree with the general sentiments expressed above, to defer making a major financial outlay that involves purchasing a battery yourself, especially if you live in a suburban metropolitan area and are a householder resident..

I wouldn’t be too concerned about just purchasing roof-top solar panels for the time being, provided you stick to the criteria that SolarQuotes recommend. You’ll still make very significant reductions in your chargeable energy usage

Oops. the full link to the picture is actually:

https://en.wikipedia.org/wiki/Alice_Cooper#/media/File:Alice_Cooper_band_Live_in_London_2012-10-28_(close-up).jpg

I wouldn’t write batteries off so quickly.

Accelerated testing, by its very nature means discharging the batteries from full to empty every time (I note some wouldn’t even do that!). It’s actually very difficult to do with high capacity multi cell batteries like these. It’s a little too much detail to go into here but things like top balancing probably don’t happen in the Test Centre or they would never get through so many cycles. Even sticking to manufacturer guidelines on C rates this constant cycling is going to artificially stress the cells and associated components. Batteries simply don’t do this in the real world unless you way under spec the capacity you need.

While I understand the results aren’t good and there are some monumental failures on the list, there are thousands of batteries out there that aren’t exhibiting these issues under normal daily use.

I’ve had off grid power for 15 years using AGM batteries and the only problems have been with inverters. I’m on my second set of AGMs (12 x 6 volt 340 amp for 24 volt system. Apart from checking connections on a 6 month ritual they remain trouble free..

A couple of questions Ronald

1. WHY do publishers frequently not label axes? Yes the article mentioned 20 months of testing but labelling the axis would have been a no brainer.

2. Where are the test results for Tesla and the Australian produced bromide (?) battery which you have suggested in previous articles?

A take note of the unreliability of batteries. As you surmise its not great news to consumers hungry for battery storage to keep electricity industry greed from the door. No point having a large capacity system if you have to pay zillions for night power.

1. I suspect time wasn’t used as a label for the y axis as it was inconsistent with breaks for repairs etc. But “approximate number of cycles” should have been fine.

2. They weren’t part of phase three testing, but my next and final article on the Canberra Battery Test Centre will briefly cover all batteries. I’ll also give links to all my previous articles on the Test Centre’s reports.

How are Graphene batteries coming along?

I noticed some small ones on the market but not sure of larger ones suitable for solar systems.

For the batteries I’ve seen described as “graphene” the substance appears to be playing the same roles as ordinary carbon in typical lithium cells. I don’t know whether or not it’s providing them with a real advantage. Time will tell, but it may be a considerable amount of time.

This whole situation is bad enough for homes, but what really concerns me are the implications for the wider government policy of basing our power supply reliability on potentially failing storage technology, for both large power grid infrastructure and vehicles. I totally love the technology, but if it doesn’t really measure up long term, what then? And we’ve all heard how cost will reduce for lithium batteries, indeed all batteries. Yet the Powerwall II batteries have only gone significantly up in cost, relentlessly!

To me, the real test will be in ten years time or so, when household and vehicle batteries show their true colours. Both cost and reliability wise.

I truly hope those colours are pretty.

I appreciate the review but given Sungrow seems to have an ever increasing footprint on the market is there any reason it wasn’t included in the review?? I for one would be interested as I invested in a Sungrow 16KW battery recently and thus far have not noticed any flaws as such, but as I said it is only a recent instillation but it seems to be functioning fine and was really appreciated in a recent brown out we had for over an hour which allowed for most of lights to function along with the fridge and the TV no complaints so far performing as expected..

I’m afraid Sungrow batteries were not examined by the Canberra Battery Test Centre.

While not being a know it all, it’s a pity that there was no information (testing?) of the lead acid battery systems. I have a report from “Mother Jones / Mother Earth” that cited where lead acid batteries are only cycled within their top 10% of power capacity and are used at the same levels as the solar panels are producing, and only for very low power consumption at night – like lights and a laptop etc., and these batteries are deep cycled and fully charged only periodically – to stir up the electrolyte etc., and they are passing 30+ years of non stop useage….

Now we all know that Hipsters and other reffos from the age of Aquarius etc., turned into nasty mung bean hating bread heads… but IF I can dig up the article I will link it.

The point is that they were not using their batteries hard at night to run the washing machine and toaster and all that…

And that they were only more or less used to feed power into the system when clouds went over, blocking the light to the panels…

Rather than deep cycling them in the evening and leaving them half charged over night to sulphate up…

Thanks Finn and Ronald for this enlightening if scary information. At our place we are 18 months into our SECOND battery installation.

The first comprised 4 x 6v 875a/hr Enersun (Japanese) cells providing about 6 kWhrs of usable storage. These were flooded lead acid cells that required monitoring and topping up with distilled water. About $1400 per kWhr installed.

Installed in June 2010 they performed flawlessly, slowly degrading until December 2021 when their capacity was down to about 55%. So about 3800 cycles.

They were then replaced with 12 x 2v Sonnenshein (German) A602/750 SOLAR cells, again providing about 6 kWhrs of useable storage. These are lead acid dryfit Gel technology that are sealed, require no topping up and can even be stored on their sides. We are into about 450 cycles with no discernable degradation. Again NO problems whatever.

Both these battery banks were/are top quality and have benefited from being charge controlled by a top quality, Australian, Selectronic SPPro. We have managed up to 5 days off grid with just 3 kW of panels.

Lead acid technology is mature and reliable. Combined with top quality charging gear it still provides the most cost effective and dependable solar storage solution. About $1000 per kWhr installed!

By comparison, I reckon the Chinese kit just doesn’t cut it.

These results make my decision to build my own system with CALB cells look even better. Im only 2.5 years in but I can replace a bad cell at a fraction of the price or just upgrade the entire bank to something with double the capacity for less than what I paid for the originals and still be way ahead money wise..

LFP has an excellent and proven long term track record so I find it surprising these results were all so bad. The reason I bought LFP is there were already those who had been using them for years, one couple for 7 years daily and that was under an abusive environment as well because the science of how to treat them was still new then.

It’s unfortunate that this article seems to have only spread more FUD about lithium batteries.

All the problems seem to stem from the commercial nature of these batteries. Lead acid is basically a DIY solution – you need someone to install them and wire them up. They don’t generally come pre-packaged in anything larger than 12V module. DIY’ing your own lithium system results in better reliability and performance as well. This lines up with ITP’s key findings:

• There is a disconnect between communication from manufacturers and distributors and ITP’s experiences on product capability (particularly integration and compatibility).

• Significant delays were experienced in battery availability and delivery, particularly for new models.

• Manufacturers appear to be moving towards either integrated battery and inverter products or battery packs that are only compatible with inverters from the same manufacturer. During commissioning in all three phases,

ITP experienced many integration issues between batteries and inverters and this step removes the requirement for manufacturers to undertake R&D and testing with external partners.

• In terms of market development, more high-voltage battery inverters and battery packs are now available. Highvoltage battery products are generally simpler to install, due to smaller cables being required.

• The number of battery failures and required replacements during the trial has been greater than originally estimated. This has been across products, i.e. a mix of established and emerging manufacturers. Although there

have been a few batteries which have not experienced any issues over the trial period, this indicates an overall continuing state of development of the technologies.

• The amount of time required for managing maintenance issues during operation was significantly underestimated and the level of support received from manufacturers varied widely. (edited to fit)

This makes pumped hydro look more attractive.

We have an fully off grid capable BYD LVS system on order. Cannot see that one in the testings. So how does that one fare?

https://batterytestcentre.com.au/wp-content/uploads/2022/06/Battlab-Report-12-Final.pdf

It’s in the attach PDF report linked above, page 7.

Thanks for that

Ronald,

Your efforts are appreciated. I have some questions.

1. What does each red dot represent?

2. Some batteries have dots all over – I take this to mean cycle performance was terribly erratic – ?

3. Does it not seem suppliers RATE their batteies TOO HIGH, i.e. performance would perhaps begin at 100%?

4. Am I correct in believing ‘firmware’ has been a major contributor to performance, rather than the storage medium, i.e. ‘battery’?

5. Is there any data available on performance of systems using EV storage? (My anticipated setup.)

My simple set up using 30yr old lead acid batteries (100% recyclable) is still working well. The key is to get the correct setup, correct maintenance and treat them in the correct way all in accordance with manufacturers recommendations.

For high power demands such as room and water heating, Heat Pump technology can be used (operating during sunlight hours) in conjunction with thermal mass and insulation in the right location.

Knowledge is paramount.