As home battery systems start to go mainstream, the focus on the safety and compliance of these systems becomes ever more critical. In this post, I will navigate the complexities of grid-connected battery system installations, uncover common challenges installers face, and underscore the pivotal role of the Australian home battery standard: AS/NZS5139:2019.

Ensuring Solar Installation Compliance

As a solar inspector, battery compliance is something I’ve only recently started to explore seriously, if I’m being honest. I’ve discovered that installers must not only possess the necessary qualifications but also undergo specialised training for each brand and product. Becoming a proficient and competent Inspector in this field requires a similar dedicated commitment; it’s a challenge!

Addressing Common Issues in Grid-Connected Battery Systems

During my relatively brief tenure inspecting grid-connected solar battery installations, I’ve encountered several recurring issues:

1. Location and Safety Zones

When installing home batteries, the placement is a critical consideration. It is important to ensure that batteries are not placed directly against or within habitable rooms unless they are installed on a surface approved for fire safety. It is also important to follow strict exclusion zone guidelines and create fireproof areas around batteries.

Materials such as terracotta, tile, brick, cement, or any substance tested to meet AS1530 standards are deemed fire-rated and suitable for battery installation surfaces. During inspections, we have encountered non-compliant installations where batteries were improperly placed under stairs, positioned too closely to windows in habitable rooms, or situated on the side of a house without maintaining the required egress distances to allow safe evacuation.

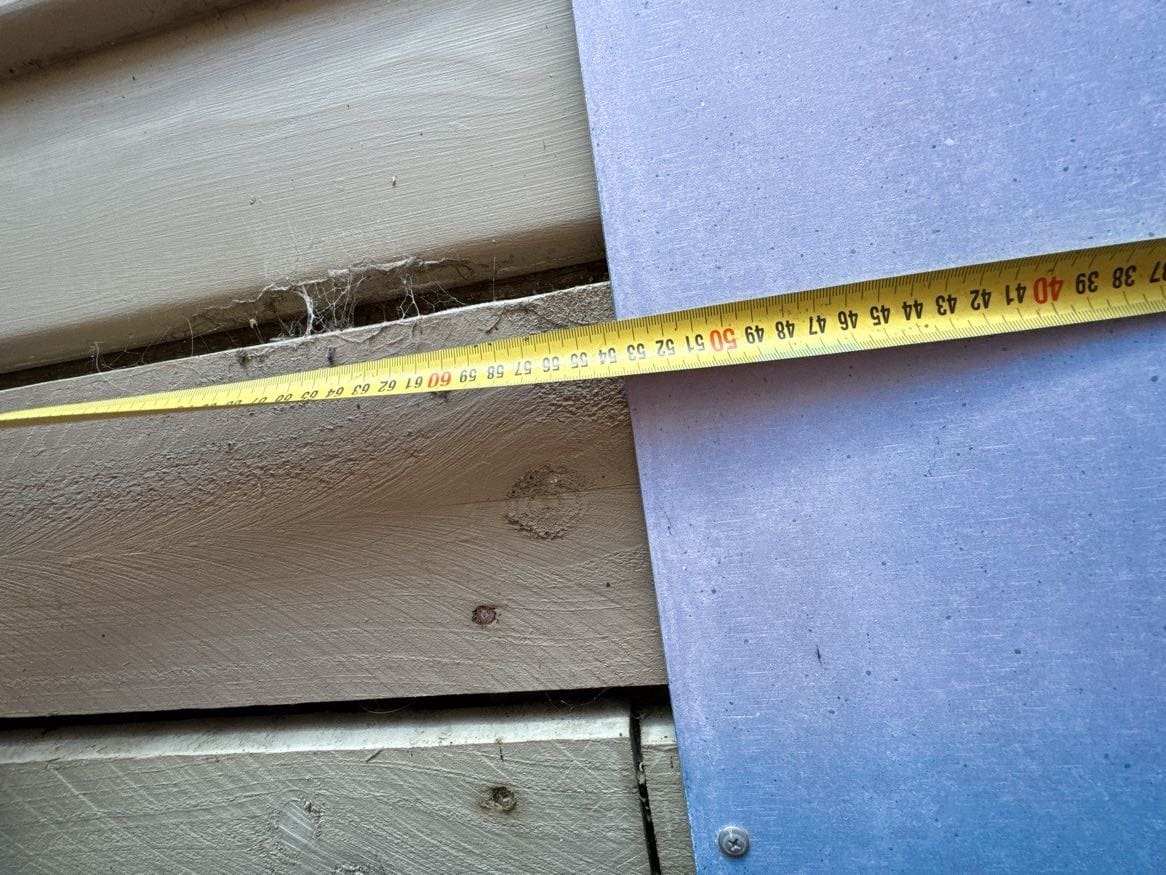

Fail: Battery located back to back with a bedroom, fire-rated material of compressed cement sheet does not extend to the minimum requirement of 600mm past the battery – exposing the non-rated material of a timber weatherboard.

2. Battery Labelling & Documentation

In the complex landscape of grid-connected battery systems, accurate labelling, signage, and documentation are crucial. Precise identification of equipment and clear instructions are not only crucial for emergency responders and maintenance personnel but are also a central focus during meticulous inspections from sticklers like me.

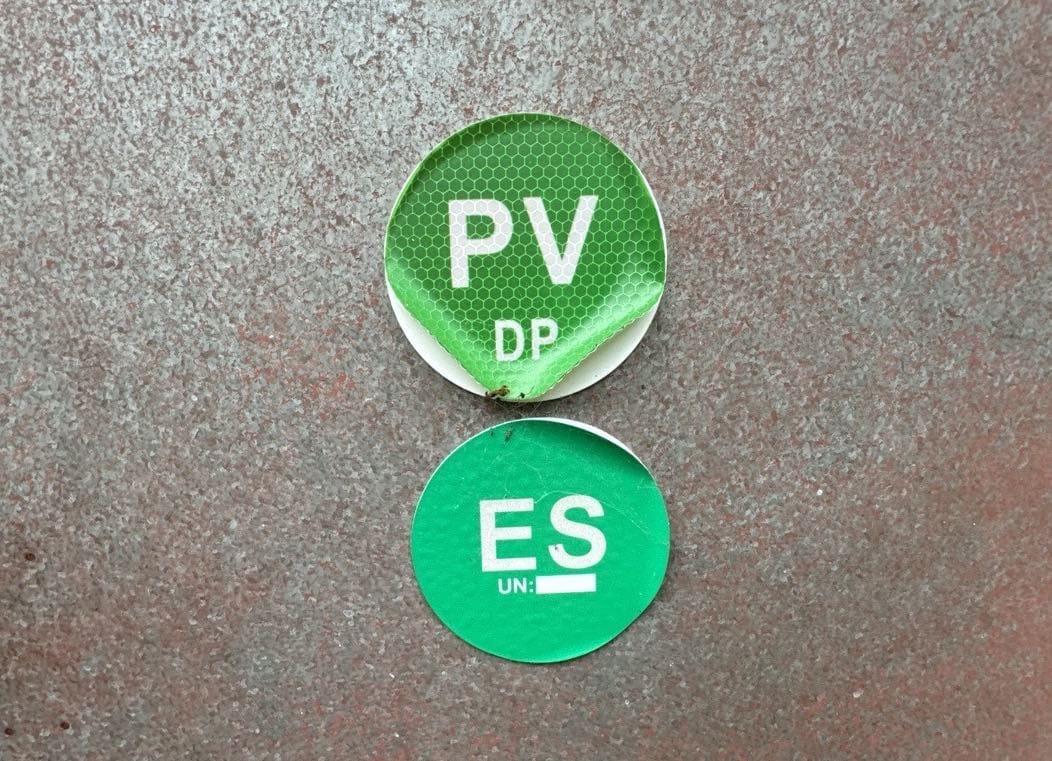

During inspections, we have encountered various issues, including missing toxic fumes warning labels, incomplete shutdown procedures in documentation, and oversights such as the absence of Green circular ES labels at the main switchboard or meter. Installers also get pinged when the chemistry code of the battery is either missing or inadequately displayed, and the Safety Data Sheet (SDS) isn’t in a designated position within a document holder at the main switchboard.

Labelling and documentation standards are vital for both informing emergency responders what they are dealing with and helping electricians with system maintenance and troubleshooting.

Fail: When a lithium-ion battery is installed, the number 3480 must be labelled on the ES (energy storage) label at the main switchboard/meter box

3. Overcurrent Protection Devices and Cable Sizing

Navigating cable sizing and overcurrent protection is a recurring challenge in electrical installations. Getting it wrong results in issues such as overheating, voltage drop, and compromised overall system performance. Australian Standard 5139:2019 ensures that cable sizes and overcurrent protection devices align.

Your installer must ensure that the overcurrent protection is sized at least to the battery’s capacity and then match the battery cables to the size of that overcurrent protection device.

Note to installers: While it may seem complex, rest assured that the knowledge you’ve acquired in AS/NZS3000 & 3008 is your steadfast companion. The fundamental concepts remain consistent. Additionally, remember to mechanically protect battery cables operating at voltages exceeding DVC-A with at least MD conduit.

Fail: The black conductors are battery cables between a BYD battery and a Fronius inverter. The protection device protecting these cables is rated at 63 amps, which does not sufficiently protect a 10mm² cable

4. RCD Protection for Backup Circuits

Ensuring the protection of backup circuits by incorporating Residual Current Devices (RCDs) is a facet that is sometimes overlooked in the battery installation process. RCDs play a pivotal role in guarding users against electric shocks. The Standard mandates the need for such protection, placing a responsibility on inspectors to thoroughly verify its implementation during inspections.

It is essential to note that any circuits designated as backup circuits must be equipped with an RCD, regardless of their initial configuration. This requirement applies universally, irrespective of whether the circuits initially had RCD protection or not. This is a common oversight frequently missed by installers. The meticulous incorporation of RCDs into backup circuits is a non-negotiable requirement.

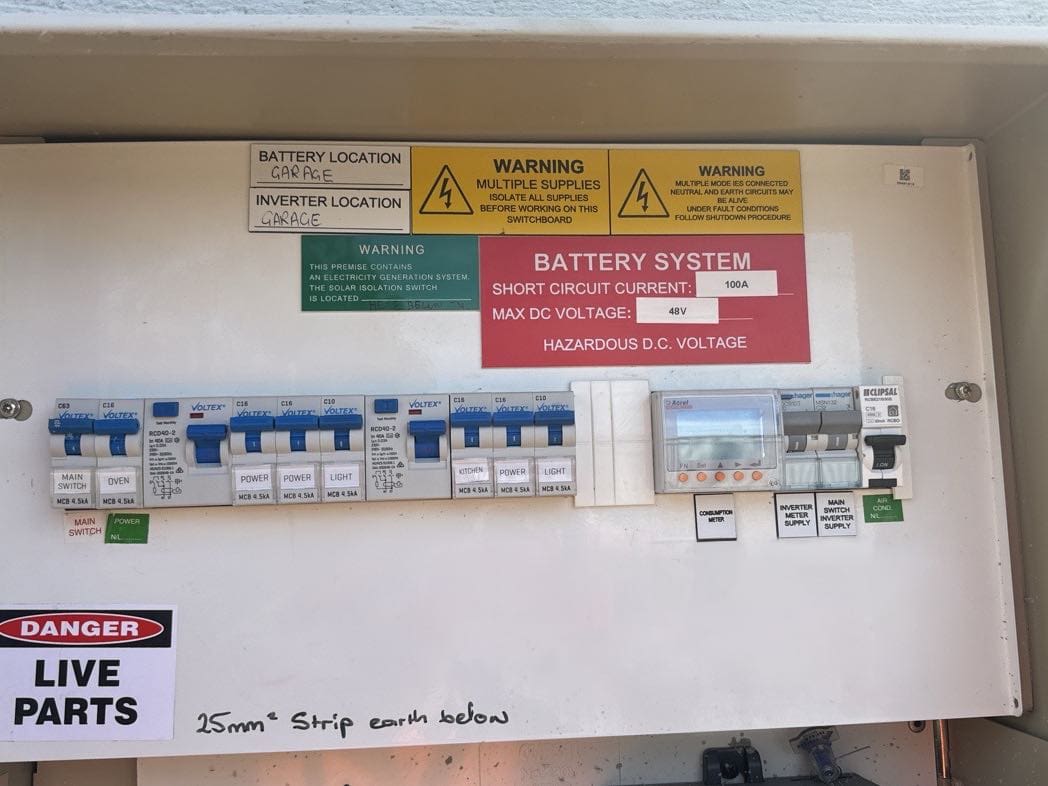

Fail: Every circuit in this switchboard is on the battery’s backup circuit. But they are not labelled as backup circuits. Also, the oven circuit does not have RCD protection

5. Mechanical Protection of Batteries

Preserving a battery’s physical integrity is paramount. Some batteries require protective bollards. The guiding principle is clear: if there exists any possibility, no matter how remote, of a battery being impacted by a vehicle, protective measures are required. Adopting a proactive approach, it is advisable to err on the side of caution.

Could be improved: One bollard has been installed. A 2nd bollard would provide mechanical protection from any vehicles.

‘Section 4’ batteries leave less room for error

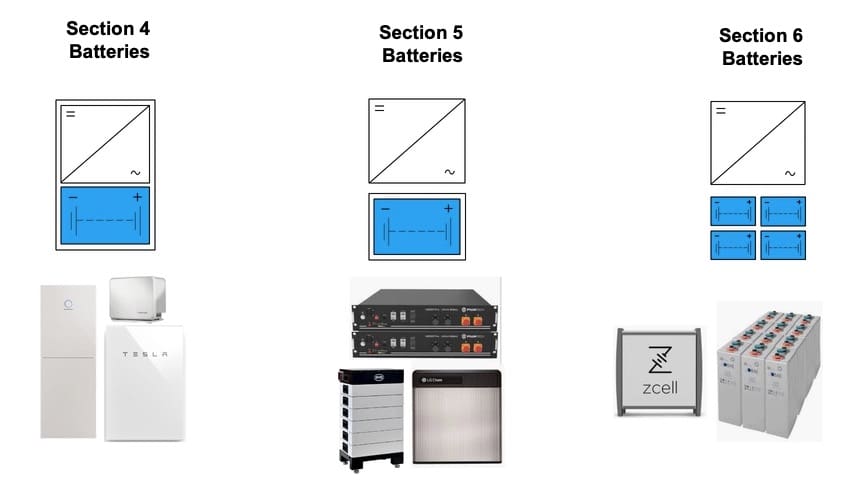

To avoid potential pitfalls, consider only installing a ‘Preassembled integrated Battery Energy Storage System’. In Australian Standard parlance, these are often known as ‘Section 4 batteries’ because they are dealt with in Section 4 of AS5139:2019. These systems use pre-wired batteries and battery inverters pre-assembled in their own enclosure, so the installer has less system design and installation work to do with reduced potential for errors.

This choice minimises complexity and increases the likelihood of a successful installation. However, it’s essential to receive proper training and strictly adhere to the manufacturer’s instructions. Section 5 batteries, where the batteries and battery inverter are separate, are more challenging for inexperienced installers. Section 6 batteries which comprise ‘everything else’ should generally be avoided by those lacking experience in the field.

Image from CEC’s AS/NZS 5139: AN OVERVIEW

By addressing common issues related to proper location, labelling, overcurrent protection, RCD implementation, and equipment labelling, your battery installer actively contributes to a safer and more reliable industry. Through education, awareness, and adherence to established guidelines, we pave the way for a sustainable and secure battery-powered future.

RSS - Posts

RSS - Posts

What are the requirements for bollards for flow batteries?

I’ve had a recent installation in my garage which does not include bollards.

In don’t have access to the standard, so completely reliant on the installer to comply.

If you need Bollards , shop at Bunnings & DIY

The repeated reference to “grid-connected” battery systems is hard to miss.

I’m busy building a fibro-cement-lined battery box for up to 60 kWh of LiFePO₄ batteries for an imminent off-grid install. That’s a lot of stored energy. We need good technical guidelines too.

Siting is in a workshop, so no vehicle threat, and on an outside wall despite the wall to adjacent habitable areas being a firewall. Each 15 kWh bank has its own BMS and 100 kA rupture capacity HRC fuse. Max charge/discharge current and max/min charge/discharge voltage are programmable for battery safety and longevity. The external wall is insulated to keep the batteries cooler in summer – mostly for longevity. (The BMS also disconnects the battery on over or under temperature.) I figure on confirming cable sizing with the installer. I’ll have to re-read AS3000, as voltage drop is a bigger deal at 48v than 230. (Incidentally, nominal 48v will be up to 58.4v for LiFePO₄, higher still for old LA.)

LiFePO₄ is renowned for not catching fire, as it has no flammable electrolytes. I’ve heard of one case in USA where a bank did cook, emitting thick grey clouds of hazardous smoke, but the smudges on the wall in contact could be wiped off with a wet cloth. I figure one or more dry chemical fire extinguishers would be a reassuring investment.

I would argue a 10mm2 cable under a 63A breaker is giving more protection than one rated to higher… (?80-100A). The idea of a breaker is to trip before the conductor is compromised. So therefore the lower rating the breaker, the higher safety margin. The breakers job is to protect the cable, the cable can’t and shouldn’t be expected to protect a breaker- that would be dangerous!

That’s of course moot if it’s supposed to have 10mm2 cable from the battery, as that would require both breaker and cable to carry 70+ amps. Would be interesting to know what the amp rating of the cable is, and then what the nearest breaker size would be…

There are some cable cross-section vs current tables in AS3000, varied for open air vs enclosed, etc.

The installer and I agreed on 2 off 70 mm² cables = 140 mm² for the battery bank with 300A fusing – three 100A fused batteries. That keeps the voltage drop down, and the I²R losses minimal despite high currents at heavy load.

12 kW = 240A at 50v, so 57600 * R watts, i.e. 57.6 watts per milliohm of cable resistance. And 12 kW is near the capacity of two Victron Multiplus II 8kVA battery inverters at 0.8 PF.

So far I’ve only pulled 12 kW when the AC solar is supplying half, and the MPPTs delivering the rest, so minimal battery drain, maybe even a little bit of charging except if a cloud intrudes.

Standards such as those put out by the Australian standards organisation are “advisory” until they are passed in legislation by the Australian goverment. If the new standard is not specified in the current legislation then its compliance is purely voluntary until it is. Form what I have been told the current legislation still references the 2008 electrical wiring standard, until it is updated to reference the new standards your are only legally required to meet the 2008 requirements. One should also be aware that if the new standard contravenes the 2008 standard then the changes will be illegal until the governement updates the legislation to reference the new standard.

Standards Australia has no power to enforce what they specify, nor do the Australian Standards have any power to overrule existing goverment legislation it is only an advisory document till the government makes the required legisaltor changes to make the new requirements law.

Hi Leigh,

You might be right for New Zealand, they have to specifically cite standards in legislation. The industry joke goes that you’re more likely to sight a tasmanian tiger in NZ than actually have the government update legislation to cite standards… and so they are still working with very old versions of these standards.

As I understand it the legislation in Australia fulfilled by regulations that in turn refer to standards. There is a 6 month grace period where you can choose which standard to use, but not mix between them. However in NSW the rules refer to the newest version, so you must change practice as soon as the new standard is released.

If the legislation actually only states “newest version” but I would be very surprised if that what it states.

From the Standards Australia website:

“Standards are documents that set out specifications, procedures and guidelines that aim to ensure products, services, and systems are safe, consistent, and reliable. Learn more here.

Are standards mandatory?

We publish voluntary standards. However, State and Commonwealth governments often refer to standards in their legislation. When this happens, these standards can become mandatory”

I believe the current legislation still refers to “AS/NZ 3001.2008” the Standards Authority is not a goverment organisation and has no power to overrule goverment legislation. Their recommendation have no basis in law till the Goverment changes the current legislation to indicate the new standard is to be used.

Hi Leigh,

If you can pull up some legislation or regulation that excludes the Australian Standards we’ll be more than happy to publish it.

Cheers

Point 4, RCDs on backup circuits should really be expanded to say that Type A RCDs are required not Type AC. This is specified in AS/NZS 3000:2018: 2.6.2.4.2.

Many houses have Type AC protecting their circuits and these need to be replaced if the circuit is on backup whether whole house or partial. At about $100 per RCBO (1ph) or $200 (3ph) this can run into $000’s.

Hi,

Standards Australia states:

“We publish voluntary standards. However, State and Commonwealth governments often refer to standards in their legislation. When this happens, these standards can become mandatory””

Not “We publish voluntary standards”

“However, State and Commonwealth governments often refer to standards in their legislation. When this happens, these standards can become mandatory”

“We do not enforce, regulate or certify compliance with standards” They can’t as they have no power to do so.

It is only when the standard is directly referenced in Goverment legislation does it become mandatory and enforcable under law.

Unless you can produce Goverment legislation that directly specifies the latest version must be adhered to then latest standard is not yet applicable but you may voluntarly comply with it if you so choose to.

…authorities that reference this document in regulation…

As I already have pointed out and Standards Australia also points out, Standards Australia/Standards New Zealand produce a recommended industry standard for best practice, it has no power to enforce such a standard but you keep pointing to it implying it is enforceable by law, only goverment legislation can do that. Show me where it is written in the current goverment legislation that AS?NZS 4777.1:2024 must be adhered to?

Hi Leigh,

I’ve got better things to do but thanks for piquing my interest. As I’ve mentioned, legislation calls up regulations which cite standards.

https://www.legislation.sa.gov.au/__legislation/lz/c/r/electricity%20(general)%20regulations%202012/current/2012.199.auth.pdf

For example I just searched the Victorian goverment legislation regarding electrical safety and nowhere does it mention AS/NZ4777.1:2024.

The thing is Leigh,

Unless you have access to the standards you might not realise that AS4777.2 actually has a normative reference to AS4777.1, that is you can’t have one without the other, so when legislation refers to regulation which mentions AS4777.2 then actually it’s both of them.

Your repeated questions are actually a great exemplar as to why access to the standards should be free, for all pedants.

Everyone could go and do things more useful, productive and in fact helpful than this colossal waste of time.

(I have found the enabling legislation for SA’s smarter home program so thanks for that)

https://www.solarquotes.com.au/blog/wp-content/uploads/2024/08/as4777.2-calls-up-4777.1.jpg

Hello!

Can a battery be installed on an internal garage wall where directly on the other side of the wall is the gas meter?

Thank you

Hi Melissa,

I don’t think you’ll have an issue as it’s inside the building while the gas meter is outside, however it’s down to your qualified installer to sign off on the job considering all the surrounds.

We have an article you can click here for more details.

Cheers

Hi,

Can a battery be installed against a colorbond steel clad wall?

My understanding is metal cladding is generally rated as non-combustible.

Thanks,

Craig

Hi Craig,

While steel doesn’t burn it does conduct heat, which could see things burnt behind it. If you build a shed on a boundary it has to have a fire rated wall and the normal approach is two layers of 16mm fire rated plasterboard behind the external metal cladding.

Best consult AS 1530.1 for answers.

do you have to have 2 bollards in front of a battery in a 2 car garage?

It says it is recommaneded by not compulsory?

Hi Malin,

I don’t have the wording to hand but technically you need mechanical protection from vehicle impact.

Some install wall mounted rails, other argue a bollard isn’t specifically mentioned and makes things less safe anyway, a few just install a bump stop for car wheels.

We’ll probably do an article on it soon.

Is there a requirement for minimal clearance in front of a home battery according to ANZ 5139:2019? All I can find is minimal clearances to the side (600mm) and above (900mm), but not in front? I have a narrow 72cm space from my home’s brick wall to a brick fence/wall that divides my property with that of my neighbour’s. The neighbour’s house is another 2m away from the brick fence/wall. Is this legal? I get mixed responses about 600mm, 900mm, but also can’t find any documentation stating any of that?

Hi Niels,

Strictly speaking I think you need 1 metre of clearance to get past a battery if it’s placed in a pathway. Putting them beside the house is going to be non-compliant in so many cases, but I suspect it’ll be a rule that’s pragmatically ignored a lot of the time.

ie There are rules about a battery not being closer than 600mm to a doorway, however if it’s a garage door, which allows you get away from the battery to exit the burning building, then it doesn’t matter *unlss you’re in NSW* where they don’t care if the doorway is 700mm or 5700mm wide.

This article might need a clarification on this point…

However some batteries also need 900mm clearance to get to the electrical connections, much like a switchboard.

So besides 600mm, 900mm, we now how have a 1000mm. I think people are assuming things and making things up. This is at the side of the house where noone ever goes, away from any combustible items other than brick. So yes, I get the access convenience for installation and maintenance, but do the standards actually specify minimal clearance in front so that we are compliant to the requirements for the battery grant?

Hi, did someone confirm the minimum clearance down the side of a house with a brick wall?

Hi Anthony – you are amazing, responding to all these questions. You may well have been asked this, but…

I am hoping to install 2 x 13.3 AlphaESS in my garage – I have a 10.3 KwH Alpha ESS which I am upgrading under the Commonwealth battery scheme. The 2 batteries won’t fit where the current battery is as that part of the wall (brick) is only 900mm wide. Because there will be two batteries side by side they will need to go against a gyprock wall inside the garage. The other side of the wall is a passageway – so not a habitable space. I understand gyprock is non-combustable. But I am thinking I will need to install some fire-resistant cladding. Is the compressed cement sheeting illustrated in your blog above suitable or is there a preferred product. I have noted the requirement to extend beyond the battery by 600+cm. Would it be suitable to simply liquid-nail the sheet to existing gyprock?.

Hi Bill,

Sounds like you’re on the right path. I would screw the cement sheet up, in the corners at least.

Have you read this post?

Good luck with the Alphas, they’re not my favourite, especially if you ever need support from the makers.

Good value when they work though I suppose.

Thanks for that. The installlers stacked the batteries – one in front of the other with the inverter above. Everything going very well. Had an app issue and Alpha was very responsive and had me fixed on no time at all. I have heard all the negatives about Alpha, but my experience has only ever been positive. Five years with the 10.3 AlphaESS. The 26kwh system seems to be a good balance for house load and enough to feed in. Zip from the grid in new set up.

Not on topic but huge thumbs up to the government’s battery program. Thumbs up also go the often-maligned Solar Battery Group.

Happy customer. Happy solar fan!

Can you please advise what clearance needs to be in front of batteries if you are creating a cover or screen for them to protect from sun and rain.

Is aluminium acceptable ?

Thank you

Hi Mike,

Your battery likely has clearances mentioned somewhere in the instructions however I would suggest you need very good ventilation in any case.

Sheet aluminium would be fine. I would line it with foilboard to reduce radiant heat for extra insulation.

Subject to manufacturer’s recommendations, I’d suggest that the most critical consideration is airflow. Convection from an open bottom through an open top, at least a foot, preferably two, below the soffit, if mounted under eaves, seems a minimum requirement for heat removal.

Temperature sensors are nice to have. My DIY battery banks currently read 20.1°C on my phone, in the workshop at 20.6°C, either because they cooled overnight, or the thermometers don’t agree. It is the Jikong BMSs on the batteries reporting to the phone app via Bluetooth. House load is 400W, just the aircon at the moment.

After system overheating on 43°C Jan 10th, my brother has replaced one 10cm fan on his outdoor inverter enclosure with a 15cm intake, and added another on the exhaust grille for better airflow. Make sure they’re Ball Bearing, not just Sleeve, for acceptable life. A cheap thermostat, also off the internet, further extends life.

Drop 10°C to approximately double battery life.