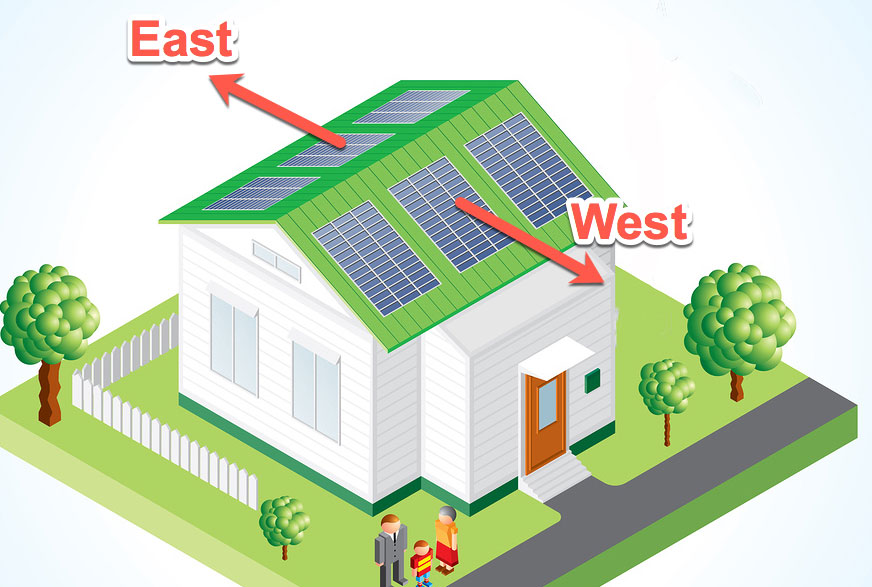

Is it OK to put East and West facing panels on a single input inverter?

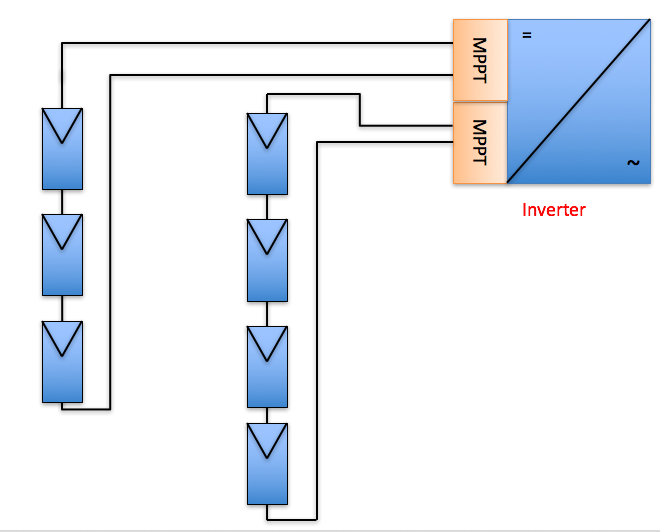

Most Australian solar installations use string inverters where solar panels are connected in series with an electrical cable. Each group of panels in series is called a string. Each string is connected into a separate input on the inverter.

1 string per inverter input

In the configuration above, each string can have a different numbers of panels and each string can face different directions. You could even have a different type of panel for each string. This is because each inverter input is connected to a separate Maximum Power Point Tracker (MPPT). The MPPTs optimise each input separately.

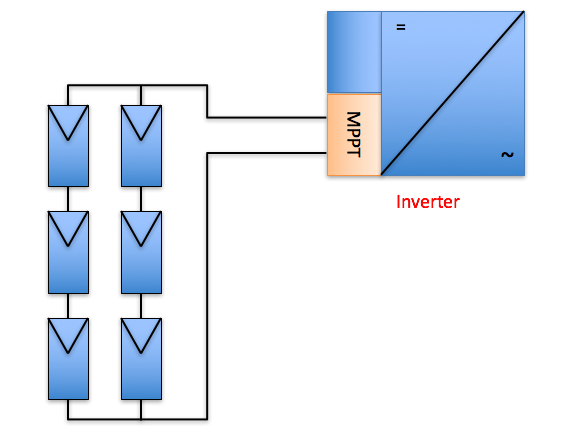

Sometimes multiple strings are connected in parallel, into one inverter input. To do this each string must have the same number of panels and they must be identical brands and models.

Multiple strings can be connected into one inverter input. The strings must be identical in terms of numbers of panels and model type.

Generally speaking all the panels in the configuration above need to be facing the same direction, or the MPPT struggles to optimise the array efficiently.

If an east/west split of solar panels is desired, where some panels are facing east and some facing west, then normally those panels would be placed on separate strings and a two-input inverter would be used.

However, under the right circumstances, it is possible to have an east/west split of solar panels on a single inverter input, like the diagram above (imagine the left-hand 3 panels facing west and the right-hand 3 panels facing east) and still have almost the same performance as if they were on separate strings attached to two separate inverter inputs.

Update: With careful design and a good inverter such as SMA/Fronius it is also possible to have a North & East split or a North & West split on a single MPPT.

Why would you want to do this? Well, a single string inverter may be cheaper than a two-input inverter, or you may want to save the second input for a north-facing array.

As well as houses with directly east and west-facing roofs, this could also be done on any building with a flat roof by using racking, including large commercial installations.

I Didn’t Believe It Myself At First

When I was told it was possible to put both east and west-facing panels on the same inverter input without a serious decline in performance, I was sceptical. I was all, “Nah! That’ll never work! When the sun isn’t directly overhead the two sets of panels will receive different amounts of light and, since they’re on the same input, the mismatch will cripple the MPPT’s optimisation and pull down the performance of the others. It’s not a good combination. Putting east and west-facing panels on a single input is like putting chalk and cheese together in a sandwich and hoping the contrast of flavours will result in a taste sensation.”

But I looked it up and it turned out to actually be correct, but only under the right circumstances.

Dietmar Is The Dude With The Dirt On Single String Shenanigans

When it comes to getting the low down on east/west splitting on a single inverter input, Dietmar Staudacher is the man to turn to. Or at least I assume he is a man. Very few women are called Dietmar. But I’m sure those women who are called that are quite impressive.

Dietmar wrote, Ost/West-Ausgerichtete PV-Anlagen Mit Nur Einem MPP-Tracker, and you can read a PDF of that paper in its original German here.

Fortunately, I am extremely talented at reading German… after it has been translated into English. And you can read a translated PDF by clicking on its English title, Efficient East-West Orientated PV Systems With One MPP Tracker.

Now note that Deitmar’s paper was published 7 years ago, which is like 7 years in solar years. There have been a lot of developments since then. But his basic conclusions are still sound.

The Benefits Of An East/West Split

Several years ago when high solar feed-in tariffs were still available, the best direction to face panels was north, so they’d generate the most electricity and allow the most feed-in tariff to be earned. But with high feed-in-tariffs, a thing of the past, except in the Northern Territory and parts of Western Australia, self-consumption of solar-generated electricity has become more important, and an east-west split of panels can help with this as it will produce a more steady supply of electricity through the day than installations where panels face a single direction.

Basic String Theory – Why An East/West Split On A Single Input Seems Like A Bad Idea

Putting an east/west split on a single inverter input sounds like crazy behaviour. Not quite as bad as installing solar panels upside down, but getting there. Apart from when the sun is directly overhead, one set of panels will always be receiving less light than the others and so will drag the performance of the whole system down. But it actually does work, because when done right, the differences between the levels of light the panels receive will not be very large and there are a couple of small advantages that help compensate for the mismatch. However, there are some conditions:

1. The two sets of panels must be identical in number.

2. They must be on a gently sloping roof.

3. They must be very close to facing directly east and west.

Update July 2020: Since this post was written many years ago, we have seen a number of examples of Australian solar systems working well with equal:

- East/West Splits that are not true East/West

- East/North Splits

- West/North Splits

They have all been with Fronius inverters and such designs are officially sanctioned by Fronius – your mileage may vary with other brands – consult the manufacturers for further advice.

4. There must be no localised shading or soiling of the panels.

The Panels Must Be Identical

Whenever solar panels are placed on a single input they all should all be identical to prevent a weaker panel from pulling down the performance of the others, so this is no surprise. But in addition to using identical panels, exactly the same number must face east as face west, so unless you know a magician who saws solar panels in half, you are going to need an even number.

The Panels Must Be On A Gently Sloping Roof

The lower the tilt of the panels, the less difference there will be in the amount of light they receive and so, the less the mismatch between them will be. To further minimize mismatch, both sets will need to have the same tilt. Good old Dietmar Staudacher put his panels at a gentle 15 degree angle.

Fortunately, there are plenty of 15-degree roofs in Australia. Fifteen and 22.5 degrees are the two most common roof pitches in the country. There is not a large difference between the two, but a 22.5-degree roof will result in a greater mismatch than a 15 degree one and is likely to result in decreased performance. I’m not saying it can’t be done, but I would expect it to slightly reduce output.

But on a flat roof, it is generally easy enough to set panels at a 15-degree inclination. Or their slope could be reduced to 10 degrees, which would further reduce the mismatch between the east and west-facing panels, at the cost of decreasing the smoothness of electricity production through the day.

Normally panels on a flat roof should be tilted by at least 10 degrees so rain will wash them clean and to prevent water pooling on them.

East & West Facing Panels On 1 MPPT Can Have Over 99% The Output Of 2 Separate MPPTs

When Dietmar Staudacher placed his perfectly aligned panels at a 15-degree tilt on a single inverter input in not-so-sunny Germany, he found that there was less than a 1% difference in output between that system and one on two separate strings. The fact their tilt was gentle and they were directly facing east and west minimized their mismatch, but there were also a few benefits that helped offset its effects.

Clouds Reduce The Amount Of Mismatch

On cloudy days, the diffuse light from the sun shining through clouds will result in a more even amount of light falling on the two sets of panels. And the German city of Kaiserslautern, which is in the area I suspect Dietmar carried out his daring deed, averages 13% fewer hours of sunshine as cloudy old Melbourne during the same seasons as when Dietmar performed his study.

Because the cloudiest place in Australia has more sunshine than the sunniest of German locations, we can’t expect results here to be as good, although the difference should still be minor.

The Set Of Panels That Receive Less Sunlight Are Cooler

High temperatures reduce the efficiency at which solar panels operate and decrease their output. When one set of panels is receiving less sunlight than the other, it won’t get as hot, and so this offsets some of the mismatch between the two sets.

Dietmar Did A Little Better Than We Realistically Can

When Dietmar did his test, rather than compare an east/west split on a single inverter to a single inverter with two inputs, he compared it to two inverters, one connected to the east-facing panels and another connected to the west-facing ones. In this situation, the east/west split on a single inverter input was found to operate at a higher average efficiency than the two separate inverters because of its more even output through the day.

However, I think the proper comparison would be with a single inverter that can accept two strings, rather than two separate inverters, and so this advantage should perhaps be ignored. This would result in the split on a single input performing very slightly worse in comparison to two strings on two separate inputs on a single inverter.

In Conclusion – It Should Work!

A properly designed east/west split of solar panels on a single MPPT can generate over 98% of the energy a two MPPT inverter would.

If you have a really complicated roof and your panels are going to be facing lots of different directions or encounter localised shading, then micro inverters or DC optimisers are the way to go, as they optimise each individual panel, so you don’t have to worry about all this string-theory stuff.

[Update Jul 15 6pm: Clarified the language, and added 2 diagrams to make it clear that the split E/W configuration is two identical panel strings, one facing E, one facing W, paralleled into one MPPT/inverter input. Clearly if all the panels were in series it would not work.]

RSS - Posts

RSS - Posts

Hi Ronald,

No penguins where I live but usually plenty down at the beach.

I am not clear on Dietmars theory. Say, I have a house in the ideal conditions as described. I presume, I then would have maximum power at midday when the midday sun equalizes the power output from the two strings. So in the morning, East, the West string would drag down the power of the East string, and visa verse in the afternoon. Now, why wouldn’t I just have a gadget which in the morning would switch off the West string, and in the afternoon switch off the East string?

John Nielsen, Silkwood.

HI John,

There is no need to do this from an efficiency standpoint – but it is done to allow connection of more panels than ‘133% of inverter rated power’ and stay inside the CEC guidelines so you can claim STC’s. Here’s an example from Glen Morris at the ASC. A 3kW inverter is not allowed more than 4 kW of panels attached at any one time according to the CEC guidelines, but this design allows 8kW of panels to be attached:

Finn,

Are you stating that Glens design will allow you to claim 8kw of panels on a 3kw inverter for STC purposes?

Kon, Ronald Brakels here. Glen’s design allows the maximum possible number of STCs that can be created with a 3 kilowatt inverter. That is, 4 kilowatts worth. This is better than the zero STCs that would be received if the 8 kilowatts of PV were installed without a switch that only allowed 4 kilowatts of PV to be attached to the inverter at any one time.

Ronald,

Yes spoke to Glen about this. I understand the theory just a little perplexed by the CEC around this pretty grey area. Thanks a lot for the feedback and putting this info up.

John, in Dietmar’s report his east/west split on a single string always generated basically the exact amount of power as having the east and west panels on separate inverters. So, if you installed an your east/west split on a single string, provided it worked similar to his, you are unlikely to gain anything from switching off one orientation late in the afternoon or early in the morning.

????? “3KW inverter with 2x4k PV arrays”

What’s the point of producing (hypothetically) 4kw from 8kw of panels? ie 4kw from each of two strings for half a day?

I say hypothetically because ample evidence clearly demonstrates the afternoon sun will never produce as much power (all else being equal) as the morning sun.

If that sort of artificial scenario were for some reason necessary one would still be much better off with 4kw of panels on am tracker. For one thing one wouldn’t lose the full benefit of the midday sun.

In any case, I can’t imagine ~ except perhaps in the most rare of situations ~ that the east/west furphy should be an issue,

eg:- there’s law that says a solar array MUST be mounted on a roof. There are some very obvious alternatives.

Hi Finn,

On average I use 7.5kW of power per day.

A 5kW system will produce about 15kW per day

With sensible energy management – taking into account peak and shoulder times – how many kW’s will my draw from the grid be reduced by (roughly).

So far – on a 5kW String system ( at $5k ) ( estimating a saving of 4 kW’s power from the grid per day) – the return for investment is in the vacinity of 10 years and not five. Obviously for a Micro System ( 5kW @ $8.5k) it is longer again.

The extra cost of the Micro makes me think I should go a 5kW East/West array with String.

Then, when battery storage becomes viable set up a North facing 3-5 kW Micro array principally to service the battery storage.

My reasoning is basically that my Supply charge ( constant with incremental increases) is about half the cost of my total energy account. Eventually the best option is to be off the grid – if feasible.

By using the cheaper String system now I am not over investing in Solar and leave the option for installing the Micro system ( which seems to be more battery storage user friendly ) at a more economic time.

This is why I thought the two systems could work well together.

In a nut shell. Buy the cheap East/West facing String now and if Battery storage becomes viable buy the North facing Micro Inverter system with the idea of getting of the grid.

Cheers again Team,

Rudy.

PS I agree with all your comments regarding our Governments attitudes towards Solar and the ‘Green’ stuff. It has a deliberately misleading mouth and a shrinking pocket. It just doesn’t care. They discrepancy between the feed in rate and the supply tariff is unjustified. It really is a matter of ‘who you are sleeping with’.

Cheers.

It can work well but it isnt to Australian standard right?

AS/NZS 5033 Section 2.1.6

PV modules which are electrically in the same string shall be all in the same orientation within +- 5 Azimuth and tilt angle.

Meaning anyone who has a system installed like this should be calling who ever installed it saying its non compliant?

From the latest CEC guidelines:

“Unless specified by the CEC system designer, the installer shall not install two parallel strings, connected to the same MPPT input at the inverter, installed on different orientations (e.g. east and west).

Note: Some manufacturers will not guarantee inverter performance where parallel strings are installed on different orientations. The system designer shall confirm that this arrangement is acceptable with the inverter manufacturer.”

So it is fine if the CEC accredited designer says it is.

Hi,

I stumbled across that paper and this article and from what I read, I think the point of the paper has been missed slightly. This setup requires two (or more) strings to be connected in parallel to one MPPT input. From the paper, the other conditions for this to work efficiently are:

– Shading must be avoided

– The number of solar modules must be identical in all strings

– Within a single string, the inclination angle and orientation of the solar modules must be identical

The reason why this works is that the optimum voltage of a panel to produce its maximum output is roughly the same regardless of irradiation level, but the current that it produces at that voltage level goes down as the irradiation drops. For an efficient system we want to keep all panels operating at maximum efficiency, so we want all panels operating at that optimum voltage most of the time. This is why shading can be such a problem – if one panel is shaded and has an irradiation level roughly half of the others in the string then roughly speaking its maximum current will be half. If connected in series with a string with unshaded panels it will limit the maximum current (unless a diode bypasses the shaded panel or an optimiser is used), and thus limits power production of the rest of the panels since the voltage since in a series of panels the voltage of each panel can vary, but current through all of them must be the same.

When panels are connected in parallel then the voltage of each panel must be the same and the current through each can vary. Now if we have two identical strings of, say, 10 panels and the two strings are connected in parallel then the total voltage across each string of 10 panels must be the same and the current through all of the panels in one string must be the same, but the current through the second string can be different.

Let’s say that a panel operates most efficiently at roughly 30V and we have 20 panels in total, 10 facing east and 10 facing west. The total voltage across the strings will be roughly 300V. If the irradiation on the west panels is 1000W/sqm and the irradiation on the east is only 500W/sqm and we have 300W panels to keep the maths simple then we’d get something like 10A through the west string and 5A through the east string. In total we’d have 15A at 300W going to the inverter for 4.5kW of power and everything would still be operating as efficiently as it can. Notice that is isn’t necessary to have the panels facing exactly east and west – they could be any direction or even the same direction at different angles, the important thing is that all there are the same number and type of panels in each string, that the panels in each string are oriented identically and that there is no shading. Reality is not quite that clean as the optimal voltage does vary slightly at different irradiance levels, but the study showed that in practice it can be close enough to not be a problem.

So, for example if you had a house with a dual MPPT inverter that can fit 8 north-facing panels, 8 east-facing panels and 12 west-facing panels then you might hook up the panels in each direction in their own string and connect the north and east panels in parallel to one MPPT tracker and the 12 west-facing panels to the other MPPT tracker. In theory, I can’t see any reason why that wouldn’t work as well as the east/west alignment on a single MPPT tracker.

Let me know if you think I’ve missed something in the study.

Regards,

Martin.

Hi Martin,

I have recently purchased & installed a Fronius Symo Hybrid 5.0kW (1xMPPT ) with a total of 6,6kW on the roof

I have 24 panels (275W each) , 12 facing direct east & 12 facing direct west with 10 degree tilt

My technician convinced me at that time to install all 24 panels In serial In 1 string to The inverter, but after Reading this article & The brilliant comments I now have my doubts

I live In The northern hemisphere/Northern europe & would very much like some feedback on my set up

I have not connected any battery storage yet & basically awaits prizes to drop

Comments are welcome

Cheers, Kasper

My inclination would be that you’d get better performance when connected as two parallel strings rather than one in series, but that being said there are a lot of factors that go into the design and I’m no expert. It is also going to depend on the exact specs and voltage/current (IV) curve of the panels on your roof. At least 10 degrees is fairly low, so even if it is not optimal, it shouldn’t be too bad.

The theory would say that your system should still perform optimally when irradiance on both sets of panels is the same, so on cloudy days and in the middle of the day when the angle of the sun on both sets of panels is the same it should perform as well as is possible.

During clear days in the morning and afternoon is when you’d expect the operation to be non-optimal. Since I don’t know what panels you have, I’m going to look at the current/voltage curve here: https://www.jinkosolar.com/ftp/EN-Eagle-270PP_rev2015(4BB).pdf. If the irrandiance were 400W/sqm on the east panels and 600W/sqm on the west panels (that may well overstate the difference in irradiance you’d actually see, but those curves are on this particular graph, so it is easier to use them).

In that case when connected in parallel, maximum power would be at about 30V per panel and produce about 100W (east) + 160W (west) = 260W per set of two panels.

Connected in series, you can’t get any more than about 3.5A out of the Eastern panels, so the Western panels also have to operate at about 3.5A with the East panels at about 26V and the West panels at about 32V for a total of 91W (East) + 112W (West) = 203W per set of two panels. Bear in mind that these are rough calculations by eyeballing the curve, ideally you’d want to be a bit more accurate than that and also base it on the specific panels that you have.

There are a few other considerations – the biggest one being shade. When connected in series, a shaded panel can be bypassed using the bypass diode and only affect the output of that single panel. With parallel strings the bypass diode activating on one panel will reduce the overall string voltage and limit what the other parallel string can produce as well. It is certainly possible with enough shading for this to negate any improvement from putting the strings in parallel.

Another consideration is the maximum input current of the inverter – I take it yours is this one https://www.fronius.com/en/photovoltaics/products/home/inverters/fronius-symo-hybrid/fronius-symo-hybrid-5-0-3-s which has a maximum of 16A input. With two parallel strings you could hit this limit at certain times (again depending on the exact characteristics of your panels) which would limit the amount of power you could get out of the system (although with 6.6kw of panels on a 5kw inverter, you’re likely going to be limited by the power output more than the max current). I’d say you would probably be OK on this one, but you need to check for your panels.

Without actually rewiring it to see, the only way I can think to see what you might be missing out on is to find comparable systems on https://pvoutput.org/ and very carefully compare your output curve to theirs on a sunny day – with orientation, tilt, location and other differences it may be difficult to find anything comparable though.

Hi Martin,

Thank you for the fast reply..

(Sorry, reply was not linked to your post above)

To be more specific I have listed the panel / inverter specs below to be more exact. I guess I am not the only one facing these east/west dilemmas

Panel specs:

– Rated Maximum Powerat STC (W): 275

– The voltage/current (IV) curve for 200, 400, 600, 800 & 10000 W/m2, it starts to drop at 30-31V

– The Max Power Voltage curves peaks at approx 30.8V

– Maximum Power Current (Imp/A) 8.93

(Mono-cryst. panel type: 24 x JA Solar – JAM6(K)(BK) -60/265-285/4BB) link:

http://www.jasolar.com/uploads/58e7330c/JAM6(K)%2060%20265-285%204BB%20F35-35.pdf

Inverter spec:

MPP tracker = 1

Max Input current = 15A

DC input voltage range: 150-1000V

Feed-in start Voltage 200V

Usable MPP voltage range 150-800V

MPP Voltage range (Umpp min – Umpp max) = 320-800V

No of DC connections 2.0

So my technician used the arguments that my

1. MPP is only kicking in at 320V so the losses I will see are far too much for optimum production when the Voltage is too low (in Denmark)

(MPP Voltage range (Umpp min – Umpp max) = 320-800V)

2. If we take Ohms law then the serial string solution is the obvious choice, but if we put up more panels (6 more) then the 2 string parallel connected solution might be better

(we have seen the Max Voltage on PV array in the log is 890V & can go up to 1000V assumed)

Agree, here in Denmark we have mostly cloudy days so the theory from Dr. Dietmar Staudacher should apply for my system.

Further the east/west orientation decision was taken as the fedd-in tarifs in DK are not even worth mentioning anymore so the Return comes primarily from the own-consumed power

Shading is not a problem

Comments are welcome

/Kasper

Hi Martin,

So I actually found out a couple of things:

1. Unfortunatly I discovered that 2-3 panels are hit during The Day by shade from The chimney (1/4 -of The individual panel is hit)

Possible solution: Can this be mitigated with DC optimizer in The parallel connected set up? I am quite sure that I still want to Go for parallel string, If shaded panels Can be mitigated!?

2. It seems that a 180degree, 25 degree tilt (South) 6,12kW plant (255W mono from 2012) from my area is producing power earlier In The morning & later In The afternoon than mine… even more power at 8am (approx double). Did some research & his MPP voltage min-max: 260-800V

Solution: What seems to be the main reason for this: Is this related to The wrong east-west serial set up at my place or related to his optimum South incl. Lower min. MPP voltage kick In . ?

My main concern is The chimney shading

Best, Kasper

If would be easier to draw conclusions seeing your production curve and voltage would provide some additional clues as well, but any mismatch between panels connected to the same MPPT input (current mismatch for panels connected in series and voltage mismatch between parallel strings) will affect overall production.

Having shaded panels will likely mean that some of the diodes kick in and bypass parts of some of the panels. This will reduce the overall voltage of the string and can cause a mismatch with an unshaded parallel string. If you can get a voltage graph from your system on a sunny day you should be able to see this effect in the graph and see how much the shade is affecting you currently and get an idea of how much more it would affect you with two parallel strings. Other things such as cell temperature also affect the voltage, but not as significantly as panels being bypassed with the diodes. Panel optimization on the panels that get shaded might help to some extent, but I don’t think you can properly address the mismatch in this scenario without optimising all panels on the roof which would be very expensive (and if you did that then you could probably address the orientation mismatch as well and leave them connected in series).

As already discussed, having panels in series with different orientations will produce a current mismatch because the panels have different illumination levels. It sounds to me like this is the reason for the south-facing system producing more early in the morning and late in the evening (it is hard without seeing it myself though).

Usually when designing a system for a roof like you have described you’d use an inverter with two MPPT inputs and put all east panels in series on one input and all west panels in series on the other input. Given that you can’t do that now, the question is whether you’ll see less reduction due to mismatch from the shaded panels in parallel or the mismatch in orientation of 20 degrees. My feeling is that the mismatch in orientation will be more significant in overall production, but even more significant when you consider self-consumption patters – the reason being that the mismatch due to different orientations will be most significant early morning and late afternoon – times when you are more likely to be using power and times when your production is well below its maximum.

Hi Kasper

I’m about to buy a setup similar to yours. So I would like to hear your experience of having East and West at the same MPPT.

/Mads

Hej Mads,

In short, E/W system works on 1 MPPT in Northern Hemisphere, but be very carefull having shaded panels during the day… this is a no go

/Kasper

Martin You The Man!!! Thankyou!!!

Hi Martin,

Thank you for the fast reply..

To be more specific I have listed the panel / inverter specs below to be more exact. I guess I am not the only one facing these east/west dilemmas

Panel specs:

– Rated Maximum Powerat STC (W): 275

– The voltage/current (IV) curve for 200, 400, 600, 800 & 10000 W/m2, it starts to drop at 30-31V

– The Max Power Voltage curves peaks at approx 30.8V

– Maximum Power Current (Imp/A) 8.93

(Mono-cryst. panel type: 24 x JA Solar – JAM6(K)(BK) -60/265-285/4BB)

Inverter spec:

MPP tracker = 1

Max Input current = 15A

DC input voltage range: 150-1000V

Feed-in start Voltage 200V

Usable MPP voltage range 150-800V

MPP Voltage range (Umpp min – Umpp max) = 320-800V

No of DC connections 2.0

So my technician used the arguments that my

1. MPP is only kicking in at 320V so the losses I will see are far too much for optimum production when the Voltage is too low (in Denmark)

(MPP Voltage range (Umpp min – Umpp max) = 320-800V)

2. If we take Ohms law then the serial string solution is the obvious choice, but if we put up more panels (6 more) then the 2 string parallel connected solution might be better

(we have seen the Max Voltage on PV array in the log is 890V & can go up to 1000V assumed)

Agree, here in Denmark we have mostly cloudy days so the theory from Dr. Dietmar Staudacher should apply for my system.

Further the east/west orientation decision was taken as the fedd-in tarifs in DK are not even worth mentioning anymore so the Return comes primarily from the own-consumed power

Comments are welcome

/Kasper

You are lucky that you can go to 1000V. Here in Australia we are limited to 600V open circuit voltage on a residential system and due to shading at my house and the nature of the Maxim panel optimisation used, reductions due to temperature and the fact that optimal operating is less than the open-circuit voltage my panels have never seen more than 400V and typically operate between 80V and 300V on a Fronius Primo 8.2.

While obviously this is not going to be as efficient as operating at higher voltages, it seems to work just fine and is the best that can be done in my situation. Assuming the DC cabling is sized well so that losses due to resistance are minimal, it is hard to see how splitting your system into two parallel strings would be problematic for voltage. There probably would be some efficiency loss, but I would have expected it to easily be less than the loss due to panel mismatch from the East/West orientation in series. I don’t have any hard data to back that up though.

I was thinking, the point of facing East/West is to have more production in the morning/afternoon with a flatter overall production curve fort he day than a South-facing system, but the mismatch is highest in the morning and afternoon which may be limiting your system. If you compare your system to a south-facing system in Denmark on a sunny day, e.g. https://pvoutput.org/intraday.jsp?id=7215&sid=5789&dt=20170829 then if your production curve is wider than that then you’re probably doing well. If it is thinner than that then perhaps the mismatch is playing more of a role. Different tilts and different shading do complicate the comparison though.

The panel data sheet can be found here:

http://www.jasolar.com/uploads/58e7330c/JAM6(K)%2060%20265-285%204BB%20F35-35.pdf

Hi Ronald,

I read the article and I would like to point out an observation. The panels used were thin film solar cells which have a better fill factor than the mono or polycrystalline cells. This would mean that it is less affected by shading/differences in panel output.

Would love to have your thoughts on this.

Regards,

Brendan

In his paper:

https://www.energymatters.com.au/images/news/2013/east-west-solar-paper.pdf

Dietmar Staudacher says the fill factor makes thin film better for east and west facing panels on the same string. Then he tests both thin film and crystaline panels and they both work well under the conditions he set. So I presume thin film would be better but it doesn’t seem to make much difference. Thin film panels have pretty much disappeared from residential installations in Australia, but I guess it could be an important consideration for some commercial or even solar farm applications.

Interesting discussion. The case discussed is split between east and west facing panels. Would the same apply if the panels were facing north-east and north-west rather than east and west?

I would expect the mismatch to be less under those circumstances, although since east and west facing panels appear to work so well it may not make much of a difference.

The trick seems to be to keep the voltage rather than in the amperage the same on both strings and of course at a high enough level so that the inverter is operating efficiently.

My roofs are at 35 degrees on the west and east side and the original article does not say anything about the inclination of the roof being critical except that all panels in one string must all be at the same inclination as eachother. I presume that there might be a problem however as my roofs/panel strings will come into full shade quite early and hence may not be able to sustain the same voltage as the opposing side given such drasticly lower amperage. I am in Sydney Australia.

Any comments/ advice?

can you install 3 panels facing 8 Degrees from north on the same string as 8 panels facing 12 degrees from north

Hi Joe

Even if the 3 extra panels are identical to the original 8 there will be a slight mismatch that will reduce the output of all panels if the additional panels don’t have DC optimizers which will avoid the mismatch problem. Installers are required to use optimisers — also called DC conditioning units — in this situation as section 7.1.3 of the Clean Energy Council Install And Supervise Guidelines For Accredited Installers States: “Modules that are electrically in the same string shall all be installed at the same tilt angle and orientation (unless using DC conditioning units).”

I did think that the guidelines allowed a 5 degree difference, so if they were the same tilt then 8 degrees west and 12 degrees west would be acceptable on the same string without optimisation. But they would have to be exactly the same tilt for that to work as both tilt and orientation cause mismatch that affects output. At 4 degrees difference there will be some mismatch, but the effect will be very small and I wouldn’t worry so long as the guidelines do actually allow it. The only ones I can find now say what Ronald quoted, but maybe there is more detail elsewhere that allows some leeway?

The guidelines state:

“7.1.3 Modules that are electrically in the same string shall all be installed at the same tilt angle (±5 degrees) and orientation (±5 degrees), unless using DC conditioning units or micro-inverters.”

So that could work for my east/west roofs (they are about 10 degrees off being exactly east/west) with a slightly different slope of 14 and 16 degrees?

Yes it could work. In fact any angles and directions could work, what is critical is that the number of panels is the same and To be aware that any shade on either side will affect both sides.

However, usually inverters have sufficient inputs so this setup isn’t necessary and it may cause issues getting an installer happy to install it that way and/or possibly cause trouble claiming STCs, so unless you have a very good reason it usually isn’t worth considering.

What if the inverter can only handle two strings and I would like the 2nd string for panels on the North? Would make sense then?

Yes it may make sense to allow three panel directions, although I’d probably only bother thinking about that if you don’t have enough East / West roof space for the number of panels you want as the difference between North and East or West is usually not that much and East plus West can give a better spread of power through the day which may make up for the lower production.

There are a number of variables to consider relating to inverter specs in particular. Some inverters won’t let you have parallel strings because they can’t handle the current. If the number of north facing panels is too low then the inverter might not have enough voltage to run efficiently. You’d have to work with an installer to see what you can do and whether it actually makes sense.

Hi,

I have got a quote from one of the preferred installers on your list.

In my situation we are using a SMA three phase inverter with 2 MPPT. And panels as Jinko tiger 390W.

The total system is 10.53 kW.

Due to the orientation of the house norther side is shorter than the east/west sides and can have maximum 8 panels.

One MPPT is having a north/east split with equal number (8) of panels and same brand as well.

The other MPPT is having only west facing panel (11 panels).

Reading the above article, am I better off using a separate MPPT for the north side; and splitting east/west on the other MPPT ? or shall I leave this as is?

To have multiple parallel strings on one MPPT they must have an identical number of panels to work effectively. Given that restriction and the number of panels you have, it seems you could have 8E, 8N and 11W as currently specified or for an E/W even split you could have 7N, 10E and 10W. There shouldn’t be much difference between those two options and they should both work fine.

One reason to go with one over the other is if you have shaded panels at certain times of the day in one of the three directions then putting that set on its own MPPT is probably a good idea, but other than or some other reason such as aesthetics, I’m not sure that it matters enough to even worry about.

Thanks Martin for the reply.

There is a possible shade on the east side as the house on that side is a double storey, ours is single storey.

Putting east on its own MPPT won’t let me put the same size of system (10.53kW).

I like the idea of having the north side on its own MPPT, is this the most efficient of the solutions?

It is hard to know how much the shade will affect it, it will have an effect on the other parallel string on the same MPPT, but it might not be much of an effect, especially if all east panels are shaded the same amount by another house as completely even shade will onlt have a very small effect on the other string.

I suspect that all the different options will work adequately and without looking very closely your situation, it wouldn’t be possible to say which is best. However, given that West is the most valuable direction for evening power and that East may be slightly shaded, the setup that minimises Eastern panels (8E, 8N, 11W) would be my inclination.

Ali – you can have North and East with the same number of panels, with each roof face as a parallel string on the one MPPT, and the West panels on the other MPPT. I’ve seen this work many times.

That should work fine with an SMA inverter as their ‘Optitrac’ algorithm will hunt for the correct max power point.

(Ronald was mistaken in his earlier reply – and I can’t blame him as the guidelines are not clear)

Thanks Finn, much appreciated.

I’m in Melbourne & looking for panels on north, east & west of my roof. East & west are roughly similar sizes with north smaller. I’ve got quotes from 3 installers on this site & they are offering me a Goodwe inverter which is apparently the only one on the market that will take 3 strings. I asked about putting 3 strings on a Fronius inverter & was told it would need optimisers & would be too difficult and expensive. No one has suggested a solution like what is described here. Am I asking the wrong installers? Is there someone who would consider this for me?

The Goodwe three MPPT inverter can accept three arrays of panels facing different directions is a convenient way of getting panels facing north, east, and west. It can be possible to have three panel arrays facing different directions without using optimizers with a flexible inverter such as a Fronius, but whether or not it is possible will depend on the roof and the number of panels, so it may not be practical.

Goodwe makes lower cost inverters but they are reliable and we can recommend them. (But note their 3 MPPT inverter costs more than their 2 MPPT inverters.)

If you want some additional quotes from installers you can trust to do high quality installations, you can get up to three through us by going here:

https://www.solarquotes.com.au/quote/start/

All our installers are personally vetted by my boss, Finn, and we back them up with our Good Installer Guarantee:

https://www.solarquotes.com.au/installation-guarantee/

How about North/South facing panels, on a gentle sloping roof?

I have filled my roof with solar panels in all four directions with 30 x 440w Risen TOPCon panels, connected to GoodWe 3 MPPT 10Kw inverter.

East and North panels are on one string, with optimizers added to all 4 x east panels. West and South on two separate strings each. However, the system is producing not even 5Kwh at 11am when all sides of roof have sun with all 30 x panels have full sun and no shade – what could be wrong?

It’s a brand new solar system, and very disappointed with such low power production. Has anyone has faced similar issue or suggest any steps to troubleshoot this issue?

Hi Pradeep,

Fistrly we need to get everyone on the same page with terminology.

https://www.solarquotes.com.au/blog/kw-and-kwh-what-is-the-difference/

Is your system subject to an export limit so that it throttles to 5kW instantaneous output?

Next time you see it at that level, and it’s sunny, turn your kettle or toaster on and the output should jump up to meet the extra consumption. Though it may not be “real time” the monitoring should respond in a minute or five to show you what’s going on.

Hi Anthony,

thanks for responding. Yes I had same thought about load and already tested by turning on the aircon and there was no significant jump in power generation. Interestingly, all three strings seem to be working but generating very low power. I have uploaded screenshots here on my google drive

https://drive.google.com/file/d/1B0nTc7DgoEGAqCX9Eh6JuCph_sFAOe2u/view?usp=drivesdk

https://drive.google.com/file/d/1Aa1nMfFaTejEd2RyX-hNhfWvHOU_o7yD/view?usp=drivesdk

Any other suggestions to try to diagnose the root cause?

Hi Pradeep,

Seeing as it’s flat lining at 5kW I think you’re hitting an export limit.

Not sure if the consumption meter has CT coils that might be on the wrong cable(?) so it’s not seeing the whole house.

Or if it’s a whole current meter which needs programming.

Best push back on your installer.

I’ve got an interesting problem … a curved roof with a Velux window in the middle and I want to install 27 panels !

Playing around in CAD has allowed me to place 4 rows in landscape orientation: the top and bottom rows have room for 7 panels and the two centre rows have 6 panels (the roof window creates a “hole” in the array).

The tilt ranges from 25 degrees at the bottom row, then 20 degrees, 15 and 10 for each of the next rows.

The inverter has two MMPT inputs with one capable of handling 26A so two strings in parallel can be connected along with a single series string.

Bearing in mind the requirements of AS/NZS 5033 (max 5 degree difference in tilt) and the requirements for parallel strings to contain same number of panels (to match voltage), and the max MPPT voltage at the inverter of 650V DC, I’m a little stuck.

The Trina panels have Voc of around 55V (temp corrected) so 13 panels (row 1 & row 2 in a series string) will over volt the inverter, so limited to 11 panels in series.

I then thought of connecting the top row to one MPPT input, and breaking the lower 3 rows into 2 parallel blocks of 3×3 panels (in series) but this has a ten degree tilt difference. The centre panel in the lower row under the window would be omitted.

Also I’m on 3 phase power and looking to install a battery so any solution will need to work with that.

Running two inverters might work, but is $$$.

Any other suggestions are welcome.

Hi David,

You can go to 1000VDC on domestic installs now, so a 3 phase inverter will handle that. (Or you could find a Fronius Primo 8.2kW Snap series, but that may not be allowed because you’d need more solar on the other phases for balance)

Fronius have great current capacity for parallel panels. REC alpha pure RX have high voltage and low current.

Tilt angle really isn’t that important.

Thanks Anthony,

I saw that the two AS/NZS standards had been aligned with 4777 now permitting up to 1000V dc. Which is very good news IMO.

However the Deye inverter (SUN-10K-SG04LP3-AU) I’ve been looking at has a maximum MPPT input of 650V.

I’ve modelled the power output for each of 12 months on the 21st (solstice etc) using the excellent NIWA solarview tool – which for NZ has actual measured insolation, as well as cloudless sky values – for any given location. You can input the azimuth and panel tilt and it will give some great info.

For example if I input the site azimuth of 346 degrees, and a tilt of 25 (being the tilt of lowest row of the 3×3 grid) I get a midday expected average insolation of 228 W/m2 out of a cloudless sky value of 648W/m2. On the other hand if I use a tilt of 15 degrees (being the upper row of the 3×3 grid) I get 211 W/m2 out of a cloudless 548W/m2.

What this tells me is that on a very clear winter’s day – which we get a lot of after a freezing night has dried the atmosphere – then I’m leaving free power on the table. (648-548=100 W/m2. At 36m2 of panels with 20% efficiency this group of panels will be outputting 3.9kW rather than 4.7kW.

However pragmatically this will probably only be one unit per day, so having to purchase this at 30cents (for say 60 days) would only be $180 over ten years. I think that becomes a rounding error.

During summer, the difference is academic as I’ll be selling back to the grid for pennies per unit. In fact the lower tilt slightly out performs the steeper tilt, so the situation is reversed with the upper panel output constrained by the lower panels.

But back to the AS/NZS 5033 requirement for a max tilt difference of 5 degrees, with the detailed analysis I can’t see the rationale. It looks like some heurestic made its way into the standard.

I have two companies coming out to do quotes this week, I’ll see what they suggest.

Cheers David,

Some of the rules are a bit ridiculous… like the legacy 133% solar overdrive guideline turned rule Australians still cling to.

> I then thought of connecting the top row to one MPPT input, and breaking the lower 3 rows into 2 parallel blocks of 3×3 panels (in series) but this has a ten degree tilt difference.

That’s the wrong way of connecting the bottom three rows to one MPPT. It seems nice an symmetrical to do it this way, but the guideline was if you are connecting strings in parallel to one MPPT then you want the same number on each string (which you have) and the same tilt within each string or as close as possible, but different tilts between strings generally don’t matter.

The 3×3 setup gives you all the panels within 10 degrees on a string which is probably OK, but it is possible to do better. For those three rows, if you connect all the top row to one string, all the bottom row to another string and connect half of the middle row to each string then all the panels on each string is within 5 degrees of each other instead of 10 degrees which will give a better result and also stay within the 5 degrees specified in AS/NZS 5033.

i.e. if we label all your 4 rows of panels are laid out as follows:

AAAAAAA

BBB BBB

CCC CCC

DDD DDD

Then you’d have one MPPT with AAAAAAA and the other MPPT with BBB BBB CCC and CCC DDD DDD in parallel.

Other options might be AAAAAAABBBBBB on MPPT1 and CCCCCCDDDDDDD on MPPT2 if 13 panels in series fits within the voltage limits and allows an extra panel on the D row if you like.

Also, MPPT1 with AAAAAAA and DDDDDDD in parallel and MPPT2 with BBBBBBCCCCCC could work and needs only 12 panels in series rather than 13. Note that this config requires 7 panels on the D row to balance the numbers.

All three configs stay within 5 degrees within a string and I’d guess all would have good performance and be pretty similar.

>All three configs stay within 5 degrees within a string and I’d guess all would have good performance and be pretty similar.

Thanks for opening my eyes. I think I will need to select an inverter that has a sufficient voltage range to work with the required panels, 13 in a string. Or select panels with a lower voltage, but then I might run into current limitations in the inverter.

I had a “salesperson” make a site visit yesterday. He is pushing Longi panels and Solax inverters. I need to send him some architectural drawings of the roof so he can finalise his quote. They sub contract the actual installation – not sure if that is a good thing.

I’m also chasing up a guy we used for solar hot water, who also does solar PV. Will be interesting to see what the two different approaches are.

… maybe you could help me understanding the Deye datasheet. I was under the impression that the Voc for the string had to be within the MPPT voltage range. But is that just where the inverter will regulate the panels along the Voltage / Current curve ?

The datasheet shows:

– Max. DC Input Power (W): 15000

– Rated PV Input Voltage (V): 800

– Start-up Voltage (V): 160

– MPPT Voltage Range (V): 200-650

– Rated DC Input Voltage(V): 550

Does this mean the inverter would regulate a theoretical 715V input to 650V. The panels show 44V dc at maximum power output (so a string of 13 is only 572V, well within the max MPPT voltage.)

What about the rated DC input voltage – what is that related to ?

Hi David,

I’ve got a post coming soon that will help you more than a mobile device will allow me on a Sunday night.

Standby for a new blog.

Cheers