Large 72 Cell Solar Panels Can Go On Home Roofs But They Must Be Clamped Correctly

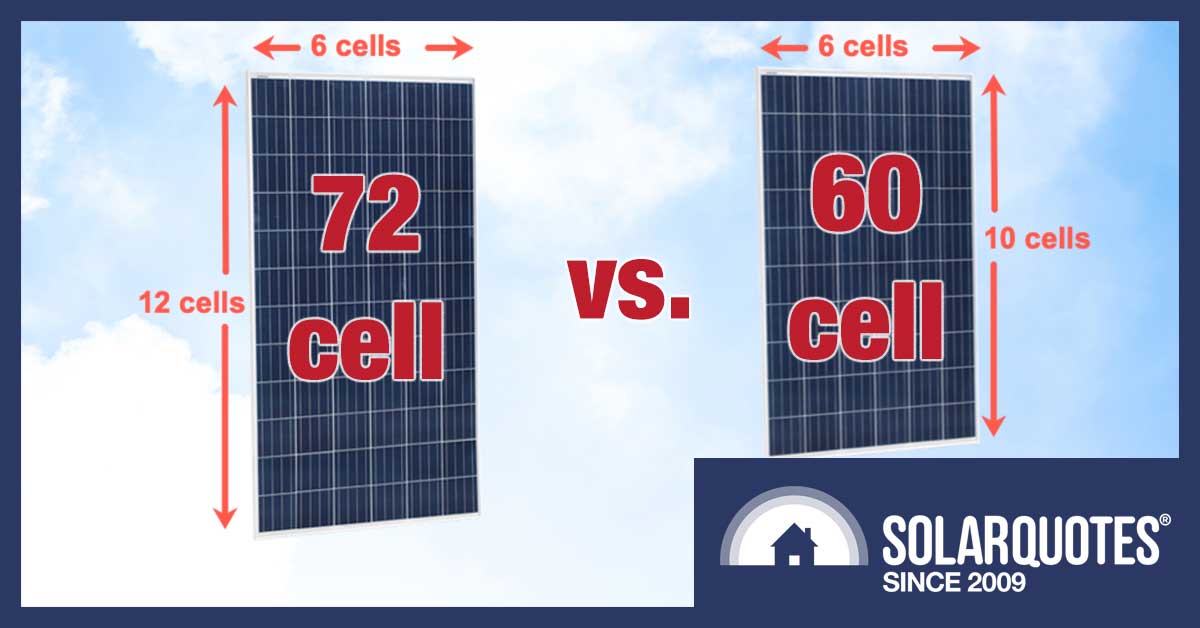

This article is about big solar panels. Bigger than the standard sized 60 cell panels commonly installed on residential roofs. Those are only around 1m by 1.65m. I’m talking about larger ones with 72 cells that are about 1m by 2m. These larger panels are mostly used for commercial installations and solar farms, but they can be used on household roofs provided they are installed properly.

Unfortunately, this doesn’t always happen.

One problem with larger solar panels is the clamps holding them aren’t always placed correctly. When the proper clamping zones aren’t used it generally voids manufacturer warranties as they can suffer damage from being flexed by the wind.

I’ll go over the main disadvantages of larger panels and I’ll cover their one potential advantage, which is cost. I’ll also explain why you should be cautious when it comes to getting a low cost 72 cell solar panel system installed.

What I won’t do is spend much time explaining what larger panels are. They’re just 20% bigger than usual. It’s nothing particularly complex. It’s not like the question of why does stale bread get hard but stale biscuits go soft.1

Half Cut 144 Cell Panels Are Similar To 72 Cell Panels

Half cut solar panels are becoming popular. These have their solar cells cut in half to provide a small increase in efficiency. A 144 cell panel is simply a 72 cell one with its solar cells cut in half. Everything in this article about 72 cell solar panels also applies to half cut 144 cell models as they are similar in size and weight, with only slightly different average performance.

3 Disadvantages Of 72 Cell Panels

Larger 72 cell solar panels are rarely used for home installations due to three main drawbacks:

- They’re larger, so it’s harder to arrange panels to fit on a section of roof.

- They’re heavier, so they’re harder to carry and haul onto roofs and safely install.

- Clamping zones — the locations where the clamps have to go to secure them to the roof — can be different from standard sized solar panels, making them more difficult to install correctly.

Big Panels On Little Roof Can Be Big Problem

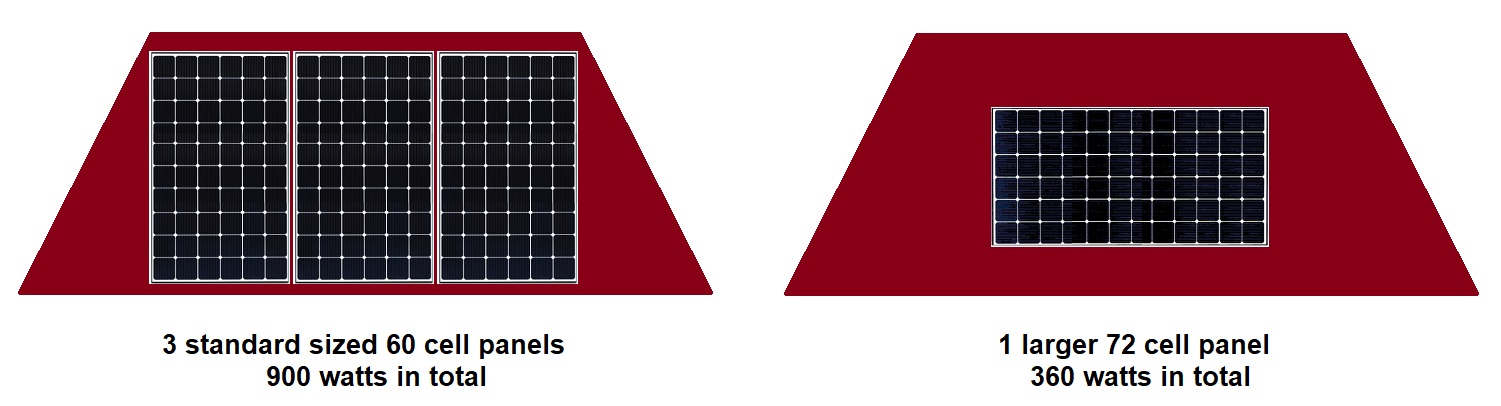

Smaller solar panels can cover more roof area. If solar panels were the size of mobile phones it would be easy to cover an entire section of roof with hardly any dead space left over. In practice, with standard sized 60 cell panels, it is often impossible not to leave a lot of empty room around the edges. With larger moduels this problem is more pronounced. As a result, a system that uses 72 cell panels can end up with less capacity than if 60 cell modules had been used.

While the problem is not always so extreme, this diagram shows how it’s possible for a section of roof to support 250% more module capacity when standard sized 60 cell panels are used. (It may be hard to see, but the panel on the right is 20% larger.)

Heavier Solar Panels Are Harder On Installers

There are various methods for getting solar panels onto roofs but most of the time muscle power is used. And muscles, as well as the joints and ligaments they are attached to, can really start to hurt after lugging a dozen or so panels up onto a roof. A typical 60 cell panel weighs around 19kg while a 72 cell module is around 22.5kg. That may not sound like a big difference, but when hauling them onto a roof it’s definitely noticeable. Larger solar panels also catch the wind more, making them unwieldly and harder to handle. This is clearly dangerous when up on a roof.

“This isn’t unwieldly! I install 72 cell solar panels for a living!”

While using larger panels means fewer need to be carried in total, from the point of view of strains and injuries, it is generally safer to make more trips with lighter loads than fewer trips with heavier loads.

The extra weight of 72 cell panels is not a problem for the roof, as it gets spread out over a similar area as when 60 cell modules are used.

Panel Clamping Zones Can Be A Problem

A major drawback of some 72 cell solar panels — their main weakness, their Achilles’ heel, if you will — is their clamping zones can be very different from 60 cell panels. Many can only be clamped on their long sides and some have very small clamping zones that leave little margin for error. The smaller the zones and the less motivated an installer is to do quality work, the more likely you are to end up with clamps outside the correct zones.

Under Australian consumer law the installer is required to fix problems caused by their incorrect clamping, but if the installer has disappeared and the manufacturer’s clamping recommendations weren’t followed, the manufacturer is likely to declare their warranties don’t apply.

Using Installation Manuals To Find Clamping Zones

To find out the clamping zones of a module you will need to check its installation manual. These can normally be downloaded from the solar panel manufacturer’s website. JinkoSolar is the world’s largest producer of solar panels and many of theirs are on Australian rooftops, so I will use them as an example of how to check clamping zones.

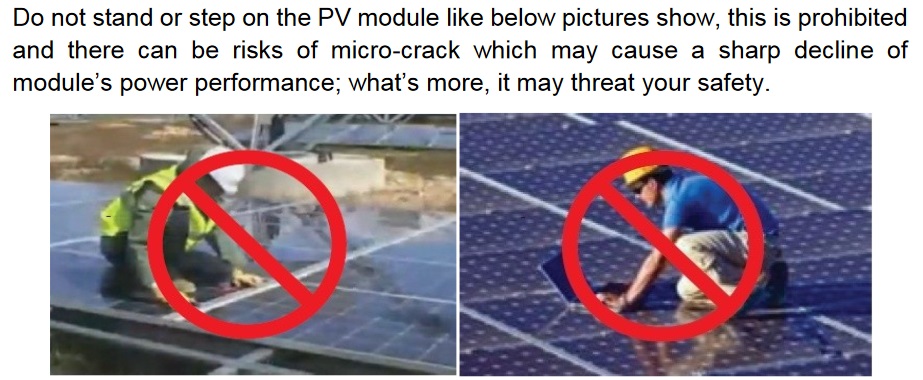

First I went to the Jinko Australian site to download their installation manual but the links weren’t working, so I instead found an older version online which was full of useful advice such as:

Remember, always avoid anything that could threat your safety.

Then I checked their site again and found it was working properly. So I went to this page and was given a choice between a UL user manual and a TUV user manual. UL is an American standards organization while TUV is a German one and relevant for Australia. (Let’s face it, Germans tend to be better at these kinds of things.) So I downloaded an up-to-date installation manual with better English and found the following information on clamping zones:

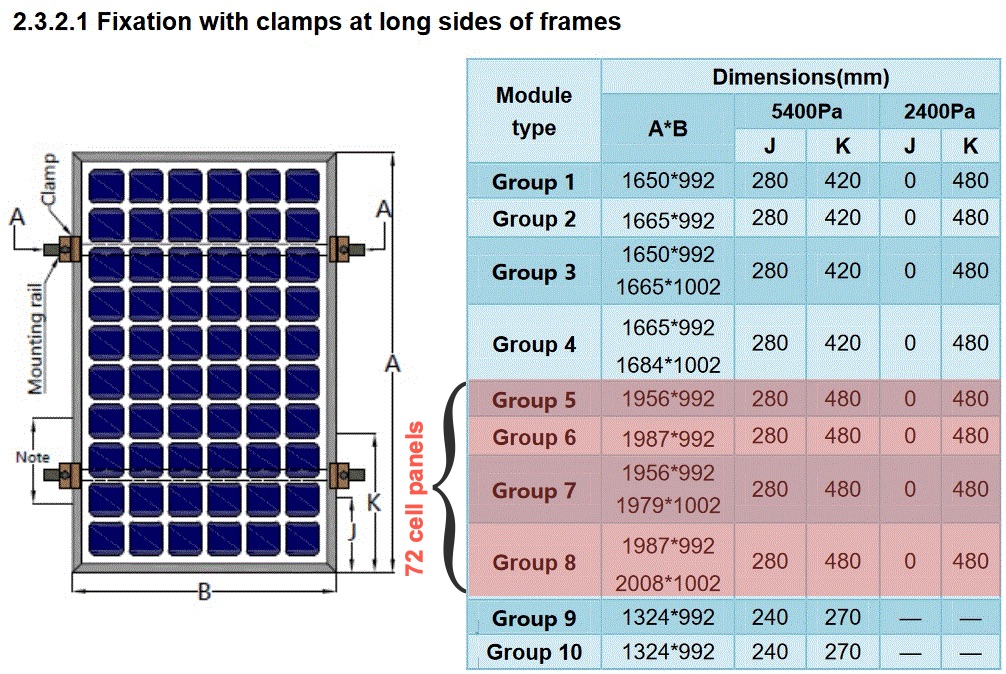

In the table above the 72 cell panels are in Groups 5, 6, 7, and 8. To work out the clamping zones you have to look at the J and K figures and there are two sets of them. One is for 5400 Pa and the other is for 2400 Pa. These are measures of how much wind pressure the modules can withstand and in Australia you will want the clamping zones for 5,400 Pa. The clamping zone is equal to the J figure subtracted from the K figure, which makes them 200mm or 20cm which is 10% the length of the module. This better than the clamping zones of their 60 cell panels that are only 14cm or 8% the panel’s length.

REC Solar Has Small 72 Cell Clamping Zones

Here is a diagram showing the clamping zones of a 72 cell REC Peak Energy solar panel:

Its clamping zones are only 10cm across, which is only 5% the length of the panel. This is less than half the length of the 20cm clamping zones on their standard sized panels. This leaves very little room for error and an installer will really have to be on top of things to ensure they are installed correctly.

Trina Panel Clamping Zones Larger Than Most

I downloaded Trina Solar’s installation manual from their Australian site, but it only gave information for clamping zones for 2,400 Pa of wind pressure when you want them to be clamped for 5,400 Pa. So I looked online and found a different Trina installation manual with this diagram:

The writing is a little small but it says to withstand 5,400 Pa of positive (downwards) wind pressure the clamps have to be located on its long sides between one eighth to one quarter the distance from the corner. This makes the clamping zones for their 72 cell panels 24.5cm, which is 12.5% the module’s length.

Canadian Solar Recommends 6 Clamps

Here’s a diagram from the Canadian Solar installation manual that recommends 3 roof mounting rails and 6 clamps be used for their large CS1U-MS panel:

When 6 clamps are used the clamping zones are 10cm, which is 5% the length of the panel. Four clamps will suffice but the clamping zones are only 8cm across, which is 4% the length of the panel. This allows even less margin for error than REC 72 cell solar panels.

The Best Clamping Zones Should Always Be Used

Some solar panels give a choice between clamping zones that are suitable for high wind and lower wind locations. In Australia the highest wind clamping zones should always be used. Even if you live in a low wind area you never know when giant willy willy might come through and cock things up.2

Voltage Issues

Standard sized 60 cell solar panels are usually rated for up to 1,000 volts while most 72 cell panels are rated for 1,500 volts. But in Australia the highest voltage allowed for residential solar is 600 volts, so it should make no difference for home solar power — provided they are installed correctly.

Unfortunately, shoddy installers sometimes don’t allow for larger panels having higher wattage ratings and install them as though they were they were standard sized solar modules. This can result in the system’s DC voltage exceeding Australian standards and the inverter’s limits, potentially creating a dangerous situation.

Their One Potential Advantage — Cost

There is only one potential advantage to using 72 cell solar panels and that is money.

When it comes to cost per watt, 72 cell panels can be slightly cheaper than their smaller 60 cell cousins. Greater savings can come from requiring less roof mounting hardware such as rails and clamps per watt of panel capacity and since fewer panels need to be installed this can save on labour.

Then there are solar companies that pay their subcontracted installers per panel. This means they have an incentive to sell larger panels so they don’t have to pay their subcontractors as much.

All this means a 5.4 kilowatt solar system with 15 large 72 cell panels of 360 watts each could be offered at a lower price than a system of same capacity that uses 18 standard sized 60 cell modules of 300 watts each.

But it’s only possible for larger solar panels to save on costs if installing them only requires the same number of roof mounting rails and clamps as standard sized modules. It’s recommended that 3 roof mounting rails and 6 clamps be used for some, which will significantly increase the cost per watt of the system.

Be Cautious With Offers Involving 72 Cell Panels

There’s no reason why 72 cell panels can’t be installed every bit as well as 60 cell solar panels provided there is suitable space available on the roof. Because they can potentially save money they may seem like a good idea. But it pays to be cautious because not all 72 cell panels are installed well due to there being two types of installers who use them:

- Those who do good quality work and want to offer good value for money and so use 72 cell modules on home roofs to keep their costs down when it makes sense to do so.

- Cheap bastards.

The problem is telling them apart.

In case you aren’t clear on what I mean by cheap bastards, I am referring to solar installers who are competing on price and willing to cut corners and sacrifice quality to keep their prices low. You want to avoid them because if you don’t you’re far more likely to have a problem with your system. Additionally, because providing after sales service costs money they’ll do the absolute minimum they can legally get away with and sometimes less than that.

Because of cheap bastards I don’t recommend leaping at an offer of a low cost 72 cell panel solar power system. Doing some research first is definitely be a good idea. One thing you can do is look up the installer’s online reviews and see if the large majority of people are happy with their work3.

If they are pushing 72 cell solar panels without knowing details about your roof or your needs I’d consider that a bad sign as it suggests they want what’s cheap for them to install rather than what’s suitable for you.

Quality Installers Rarely Use 72 Cell Panels

Under the right circumstances 72 cell solar panels can be every bit as suitable for a household roof as standard sized 60 cell modules. Despite this, not many people I consider to be high quality installers use them, despite the potential for cost savings.

This may seem odd because they are running businesses and keeping costs down is important. But I think it is simply due to the following factors:

- Because 60 cell panels suit a greater number of roofs a quality installer is likely to start with them as their default assumption.

- It can make installations easier to always stick to the same panel size and get good at installing them. Standard sized panels are also safer to install.

- There can be benefits to buying one size of panel in bulk and using them for all installations rather than occasionally buying larger modules when the situation calls for it. (The cost advantages of buying in bulk are very small, but so are the cost advantage of 72 cell panels.)

While it is possible more 72 cell solar panels will be installed on large home roofs as installers seek out cost savings, I don’t expect to see any large shift to using them residentially.

Footnotes

- The logical answer is, of course, that bread is made of stale biscuits and biscuits are made of stale bread. ↩

- Technically a willy willy isn’t the same as a tornado and can never be nearly as powerful. But Australia also has tornadoes and one of them might come and cock things up. (Or would that be an anti-tornado since they spin clockwise in the Southern Hemisphere instead of anti-clockwise?) ↩

- and always make a point of looking at their worst reviews – see what they did to earn those low scoring reviews. Was it an honest mistake or something more sinister? ↩

RSS - Posts

RSS - Posts

beware of sellers selling you a high efficiency panel of 330W and it turns out a 72cell panel of average efficiency.

72 cell panels have their place on residential roofs, we use them only on easy access roofs where there are limited screw lines so we can get the largest system on their roof for the best price.

For my 1st solar system I got 25x BenQ (now AUO) Sunforte PM96 with 96 cells at 330Wp – size is 1559mm X 1046mm – Vopen = 57V.

Just recently on a cold April day I got 100% system performance with 5years old installation (sure I am on North hemisphere).

All runs on a SMA Tripower 8000 inverter.

Sure it was not cheap – but I am happy everyday what I got!

Also Ronald another issue that I’ve witnessed with 72 cell modules is installers not adhering to the 600v DC residential limit.

I have broken all the rules with my installation.

Landscape on a tiled Roof with Commercial (72c) panels.

When I first suggested this, many installers and forum “experts” ran for the hills or questioned my intelligence in new and colourful ways. There were many excuses, fortunately the there were some experienced people that were able to explain the few genuine concerns.

1. 72c Panels are >20kg which exceeds OH&S regulations for 1 dude on a ladder. (You need 2 Dudes and a lift)

2. Clamping zones (as you described)

3. Bearers for Track Footings are difficult to find in valleys or near ridge capping.

The Reasons For:

1. Maximize Self Consumption

2. Maximize Production

3. Avoid Optimizes required for a 3 aspect installation

I am constrained by my inconvenient roof line. It has “easy install” areas on the South and East and MC Escher Inspired North and West (Self Consumption) Faces.

I have enough room for 18 Panels, regardless of size.

18 x 370W = 6.66 kW (Magic!), Job done. Or so I thought.

Then I looked into racking and clamping zones.

My original thoughts were true landscape (Horizontal Tracking), my tile spacing allowed for the horizontal Rails to match the clamping zones, but there is a catch. Footings locations were hard to come by and the larger panels need a center support if you clamp on the short side.

Then I looked into “Rotated Portrait” (Vertical racking) – This is where the “No Landscape on Tile” rule comes from.

My Bearers are all 600mm, Too wide or too narrow for 5400 MPa rated clamping zones…….on a 1.65m panel.

But on a 1.95m Panel, they are in the sweet spot. A diagonal offset of 600mm may be a little ugly but gave me 3 rails preferred for mounting.

At the end of the day my advice is to be open to possibilities whilst understanding limitations.

A number of installers I spoke to have a series of standard rules of what they are prepared to do. In reality, they are guidelines to make installations simpler for them. Some didn’t seem to care much what was best for me.

A shout out to a couple of Perth installers that have helped me through this process. I got the larger Panels cheaper but paid extra for the additional racking and footing materials required. Transparency has been the key

Closing Thoughts:

A panel generating power to the grid is 75% less efficient than a panel generating for self consumption. It is important to invest time and money to get an optimal layout.

“A panel generating power to the grid is 75% less efficient than a panel generating for self consumption.”

How?

I can see how it would affect financial outcomes, but not panel efficiency.

Generate 4 kWh in the morning so that you can use 1kWh later that afternoon.

1/4 = 75%

I probably should have used the phrase “cost effective” or rephrased it to: $/Watt consumed cost is four times……

As a resident, it is the big picture that matters..

.

Good to read your advice Howard keep it coming. I think it might be worth another look at clamping though. 5400kPa loading is for snow loads. In most of Australia we have no snow and mostly wind region A so 2400Kpa clamping is the norm, which means clamping is more flexible. E.g for 60 cell 1650x992mm panels, Trina and Suntech allow clamps anywhere from end of panel to 1/4 length, Jinko allows end of panel to 480mm in. Mind you it isn’t easy to decipher this, most installation instructions are a little unclear, complex and require confirmation from the manufacturer!

Cheers David Bartley NSW

I couldn’t agree more with what you’ve written. While I think the article has some very valid points I also think it’s ultimately slightly misleading.

One has to match the requirements of the inverter with the specifications of the Solar modules… whether they are 60 cells or 72 cells doesn’t matter.

“A 144 cell panel is simply a 72 cell one with its solar cells cut in half. Everything in this article about 72 cell solar panels also applies to half cut 144 cell models as they are similar in size and weight, with only slightly different average performance.” I´m afraid I cannot quite agree there unless you only talk about mechanical characteristics. The 144 cell panel has six cell strings, 72 cell panel has three cell strings. If the connection box has six diod´s, one for each string of a 144 cell panel, you can consider it two 72 cell panels connected in parallel. If the connection box has three diod´s you have a problem, then you have two 24 cell strings connected in parallel and also connected in parallel with one of the three diod´s. Consequently the diod cannot work as intended when a cell is shaded, it will only work if only one 24 cell string is connected in parallel with the diod. A 144 cell panel have to have six diod´s and be arranged like two 72 cells panels in parallel. Or even better have four connection wires to the two 72 cell panels in a 144 cell panel making it possible to connect in series or parallel as you wish.

.

Hi

You’r right on several points, for sure. Never walk on modules as we can see ofently on promotionnal pictures. That’s the better way to break them.

Right also about engineering and german process. They are really good in solar plants.

In all case that’s a good post about the question.

Concerning myself I use the 72 cells to reduce the cost of Wp on solar trackers

Regards

The REC 72 cells now have extra support so the clamping zones have been relaxed. That is an old spec sheet.

Good to know, although that is what I got from their site.

can you tell me why when it rains the water beeds up on the panels, we have all of them beeding up except 1, when i contacted the company (solar harness ) i was told the panels have only been on your roof for just over a month & that next time its raining i should climb up on my roof & take a photo & send it to them rather than them to come on out to see if there might be a problem ( considering the company knew i was recovering from 2 shoulder operations i was disgusted in their response & lack of care. Any information would be appreciated from you

regards Brian

Water beading up on panels is not a problem provided they are at an angle of at least 10 degrees so the water will flow off them when it rains. If they were installed at an angle of less than 10 degrees then your installer should have warned you that water sitting on the panels would likely be a problem. If they are installed on a normal, angled roof it should be fine. Don’t go up on your roof, just check they are producing a reasonable amount of energy, taking into account that it is winter. If you want, you can use this page:

https://solcast.com/rooftop-solar/free-pv-system-performance-estimation-tool/

To determine about how much energy your solar system should be producing.

Por que sistemas solares maiores são mais baratos e perigoso em 13 estados Brasileiro + distrito federal trifásico 380V ?

Quando você pensa que uma decisão é trabalhosa e, portanto, cara, você usa 24 painéis solares de 60 células até 1000 vdc, ligados em série com tensão de circuito aberto 38.5 vdc 8 strings de 24 painéis em cada inversor 924VCC x 1.8 = 1663 VDC contra 1000 VDC em 13 estados Brasileiro + distrito federal trifásico 380V. Você é louco ? Quando você começar a sentir remorso por um ato que sua razão lhe diz que não é imoral e perigoso, examine as causas do seu sentimento de remorso e convença-se dos absurdos delas. Então, você integrador, lembre-se que a ART é sua, a responsabilidade é sua, e vidas humanas e patrimônio estão em jogo. Pense nisso antes de usar a String Box CA + CC, por que o fabricante falou que pode. Seu projeto solar on-grid corre um grande risco de incêndio. Por quê? A tensão mais alta permitida para energia solar residencial para painéis solares 1000 VDC de 60 células é 450 VDC. Daqui não passa. Se você elaborou um projeto energia on-grid com tensão superior a 450 VDC para painel solar de 1000V no circuito aberto, então você é um engenheiro de merda. Leve os cadáveres de todos os painéis solares de 1000V mortos cabos solares de 4 mm, inversor e string-box para autópsia para descobrir por que eles morreram tão jovens.

Thanks for the article; good points. Many of the split cell panels have two separate wires on opposite sides of the panel instead of coming out of a centered junction box. This is fine for stringing in series to a central inverter, but creates additional considerations if going with microinverters(will likely need extensions on the cables). The cost of adding a microinverter to each panel is another argument for fewer large panels instead of many smaller panels.