The Canberra Battery Test Centre has released their latest six monthly report. It took them 9 months to get it out, but I’m glad they took their time, as it’s a beauty. It gives information on the performance of every solar battery they’ve been able to successfully test and can be downloaded here.

I originally wrote about the Battery Test Centre a year ago and covered their September report here. Today I’ll go over the highlights of the latest report. Some good news is:

- The Sony Fotelion lithium battery retained 87% of its original usable capacity after testing that approximates 10 years of household use. This demonstrates it’s possible to make lithium batteries that only suffer moderate degradation.

- Solar battery efficiency does not appear to decline with use.

Unfortunately, there’s also plenty of bad news:

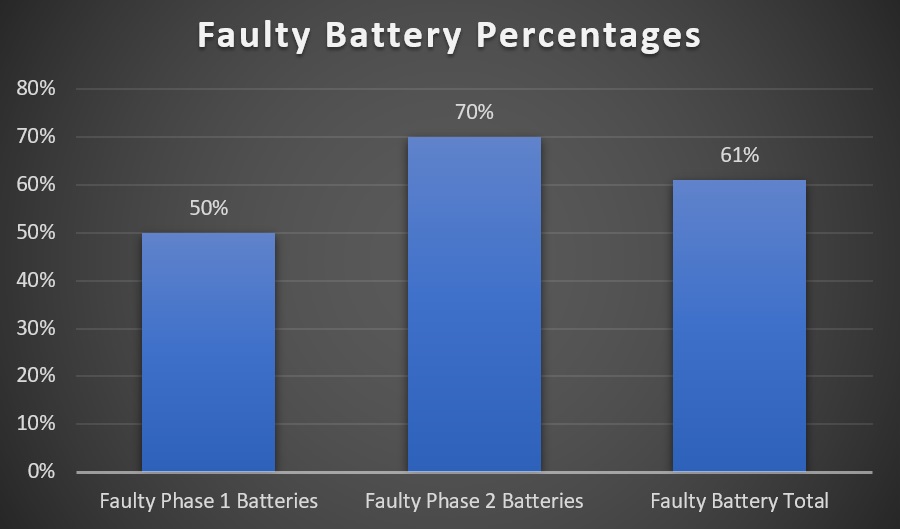

- Out of the 18 batteries tested only 7 did not develop a fault or already had one when delivered.

- Rather than improving with time, newer solar batteries used in Phase 2 testing were faultier than older Phase 1 models.

- Total round trip efficiency of lithium batteries appears to only average around 84%.

- The solar battery systems tested have shown little overall decline in price for two years.

Battery Trouble

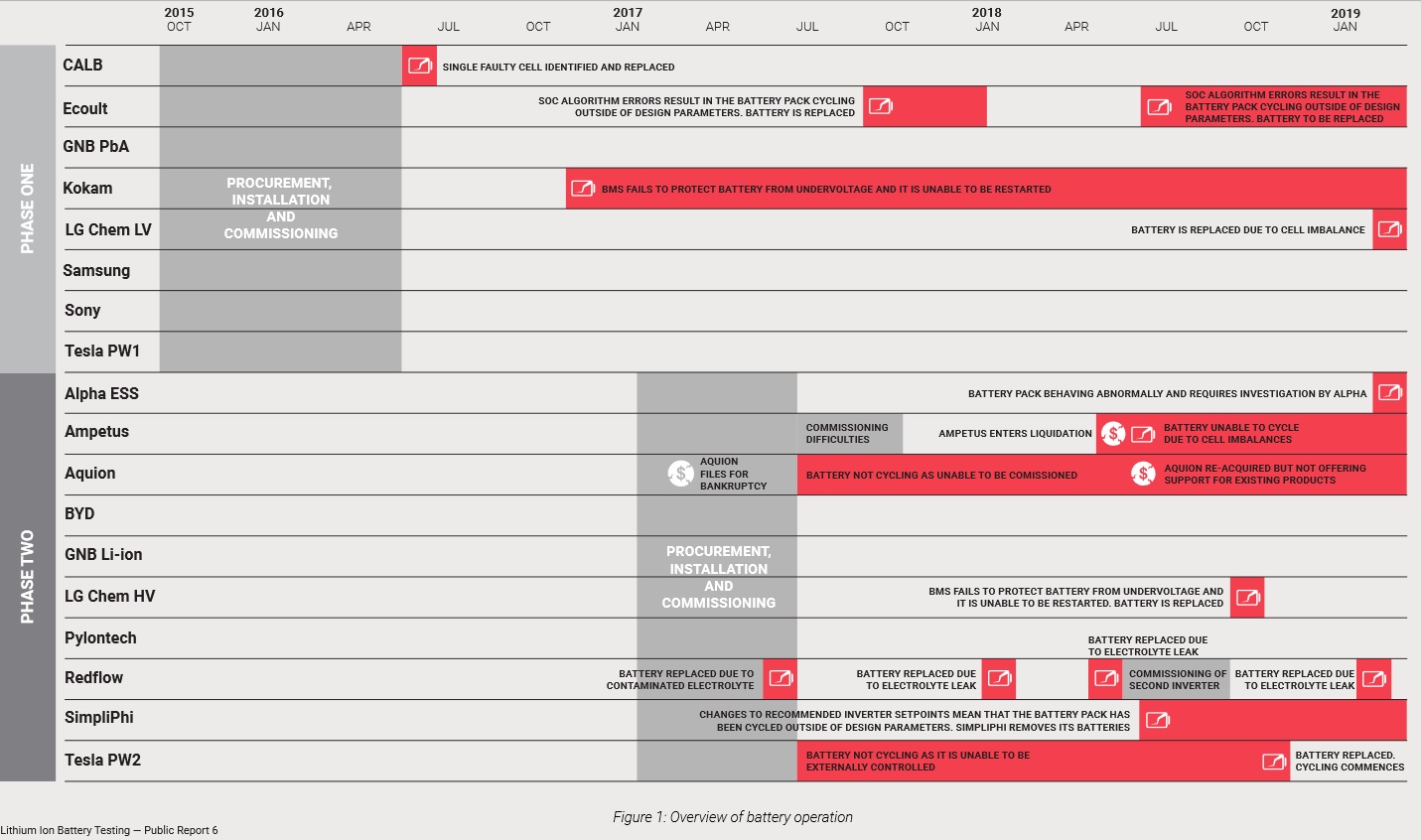

When I first wrote about the Battery Test Centre I reported things did not look good for anyone wanting to own a problem-free residential battery. The situation has — predictably — failed to improve with time. The chart below was taken from the latest report and the red parts of the chart indicate battery trouble:

Don’t worry if the chart is difficult to read because I’ll save you the trouble of going through it by pulling out the most shocking1 details.

Majority Of Batteries Faulty

Of the 18 batteries tested only 7 didn’t arrive with or develop a fault. Using advanced finger mathematics I determined that’s under 40%. Three of the so far faultless solar batteries haven’t finished testing, so the percentage could worsen.

It would be nice if I could report the 10 newer batteries from Phase 2 testing were less faulty than the older, original, 8 models from Phase 1 — but the opposite is true. While half the older phase 1 batteries were fault free, only 30% of the newer phase 2 units have operated okay so far.

Not all faults were equal. Some problems were detected rapidly and rectified under warranty with little interruption in operation. For others the situation was more serious. In the case of the Aquion Salt Water Battery, the Battery Test Centre was unable to install it and couldn’t get any assistance because the manufacturer went bankrupt. If a home owner had bought that Aquion they’d be completely out of pocket because the street value of salty water isn’t very high.

The importer of the lithium Ampetus battery also went bankrupt and wasn’t around to honor their warranty when it decided to turn into an expensive brick. Two out of 18 means 11% of tested solar batteries failed because warranty support was not available.

While a household would have been out of luck with the Aquion or Ampetus battery, I think the award for bad luck combined with dogged perseverance would have to go to Redflow. So far they have replaced their ZCell battery four times. Once because it had contaminated electrolyte and three times because it developed electrolyte leaks. Redflow has changed the manufacturer they use and I can’t say I blame them.

Capacity Decline — Phase 1 Batteries

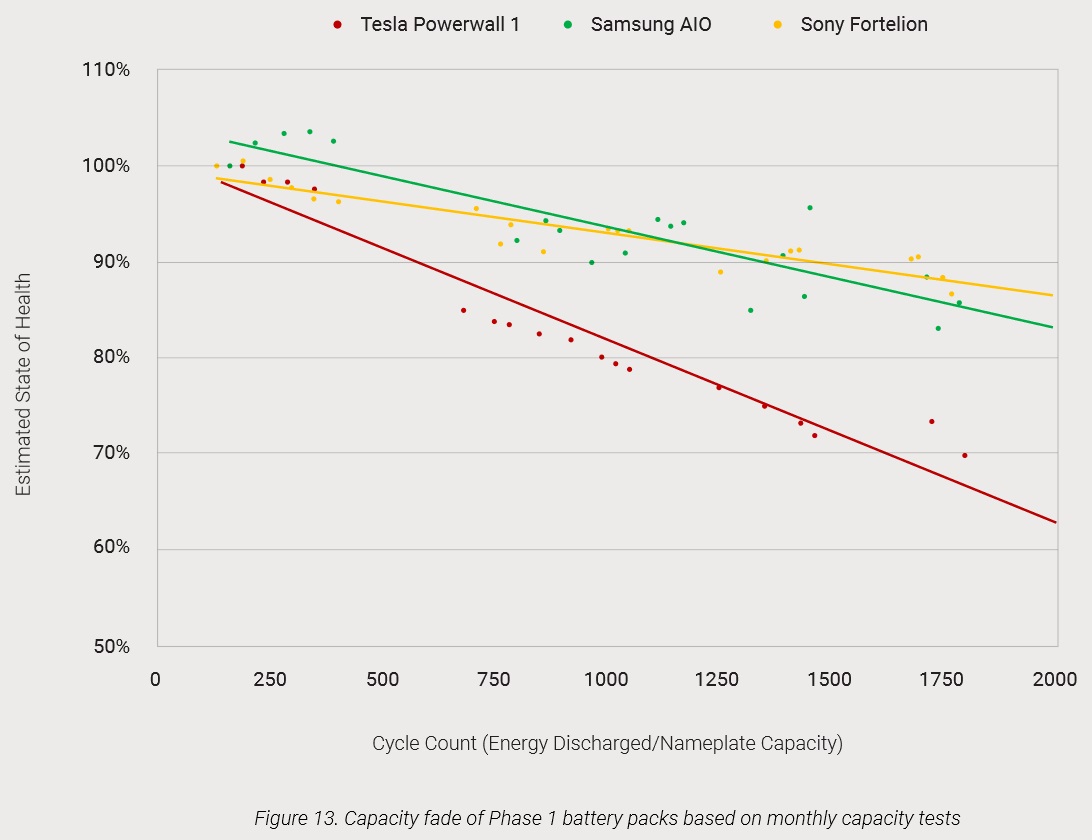

With very few exceptions, batteries decline in capacity with use. Accurate information on the usable capacity over time could only be obtained for 4 of the 8 Phase 1 batteries. One of them was lead-acid. The graph below shows the deterioration in capacities of the 3 lithium solar batteries:

On the graph above 2,000 Cycle Counts should roughly correspond to 10 years typical household use.2 The Sony Fortelion had around 88% of its original capacity at the end of testing and is predicted to still have 87% at 2,000 Cycle Counts. This is an excellent result and, despite being one of the older Phase 1 batteries, was the best result of all those that could be measured. This shows lithium ion batteries can be very durable. But this excellent performance came at a high cost in the form of a high cost. The Sony Fortelion was expensive.

The Samsung AIO (All In One) also did well and is predicted to have 84% of its stated original usable capacity at the 2,000 Cycle Count mark. The original Tesla Powerwall was the worst of the three but, because of hardware limitations, its testing was harsher than the other two and this could have contributed to greater deterioration.

Capacity Decline — Phase 2 Batteries

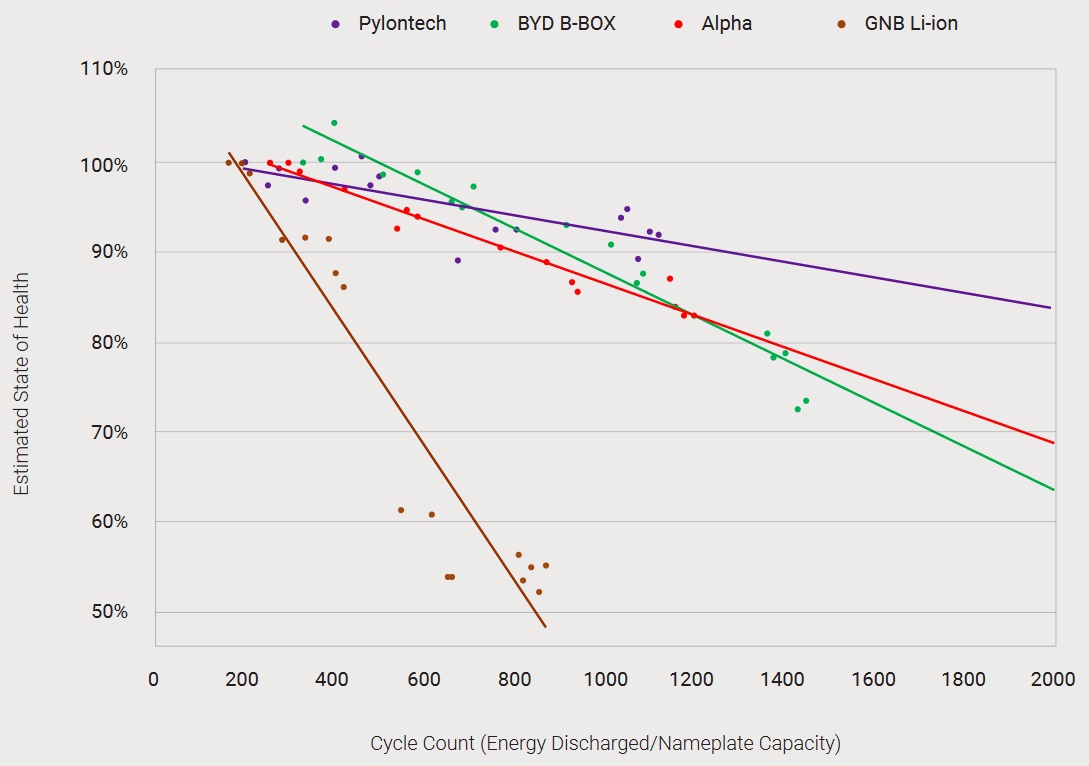

This graph shows the decline in usable capacity of the 4 out of 10 Phase 2 batteries that were able to be measured:

Testing of the Phase 2 systems isn’t complete, but so far the Pylontech battery has proved to be the most durable and is on track to retain around 84% of its original usable capacity at 2,000 complete cycles.

At the moment the BYD and Alpha ESS batteries are more or less neck and neck. When I wrote about the Battery Test Centre’s previous report I pointed out the BYD battery was doing well, but unfortunately its deterioration rate has increased. Alpha ESS has said their solar battery is faulty, so it’s possible if it was working properly its deterioration would be less.3

The GNB Li-ion has clearly suffered the worst performance and appears to be faulty.

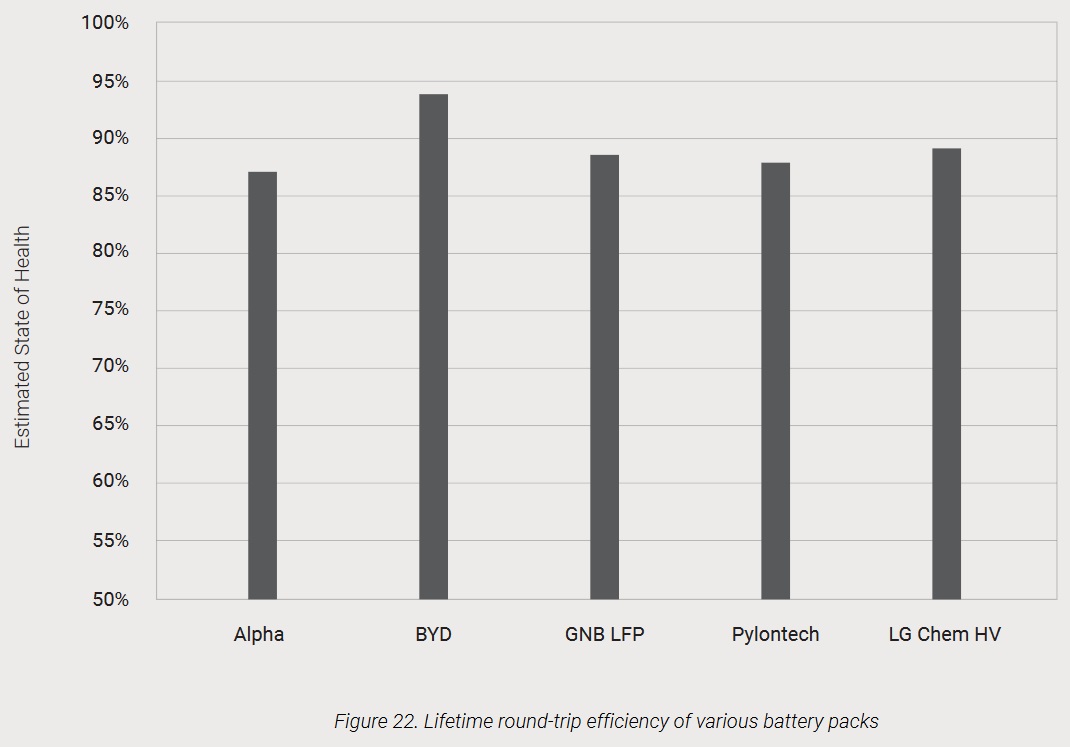

Efficiency Doesn’t Decline With Time

The good news is the round trip efficiency of solar batteries — how much energy you can get out compared to how much you put in — doesn’t appear to get worse over time. The graph below shows the round trip efficiencies for all the Phase 2 units that are in operation:

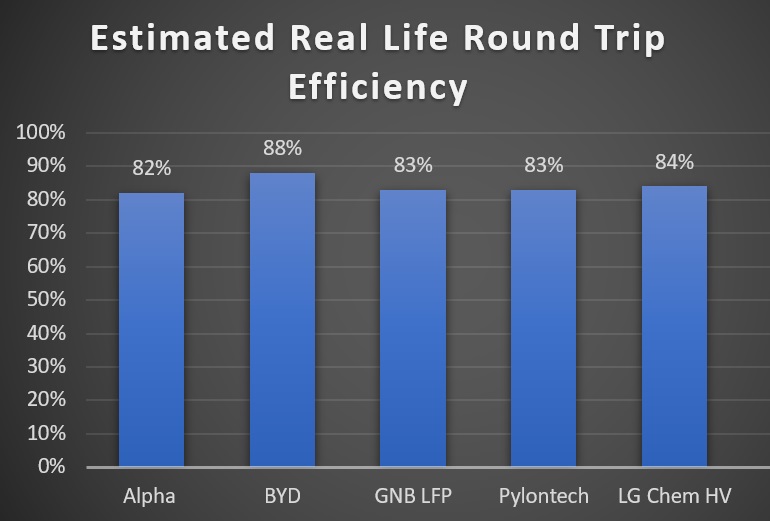

They range from 87% to 94%, but this is only the DC to DC efficiency. In practice there will be additional losses4 and I estimate they are likely to be around 6%. The exact amount will vary between systems. The graph below shows the round trip efficiency figures with an extra 6% loss included:

While a BYD system does well with an estimated 88% round trip efficiency, the average of the 5 is only 84%. This means a typical solar battery system will consume around 1.2 kilowatt-hours of electricity for every kilowatt-hour of stored energy it provides.

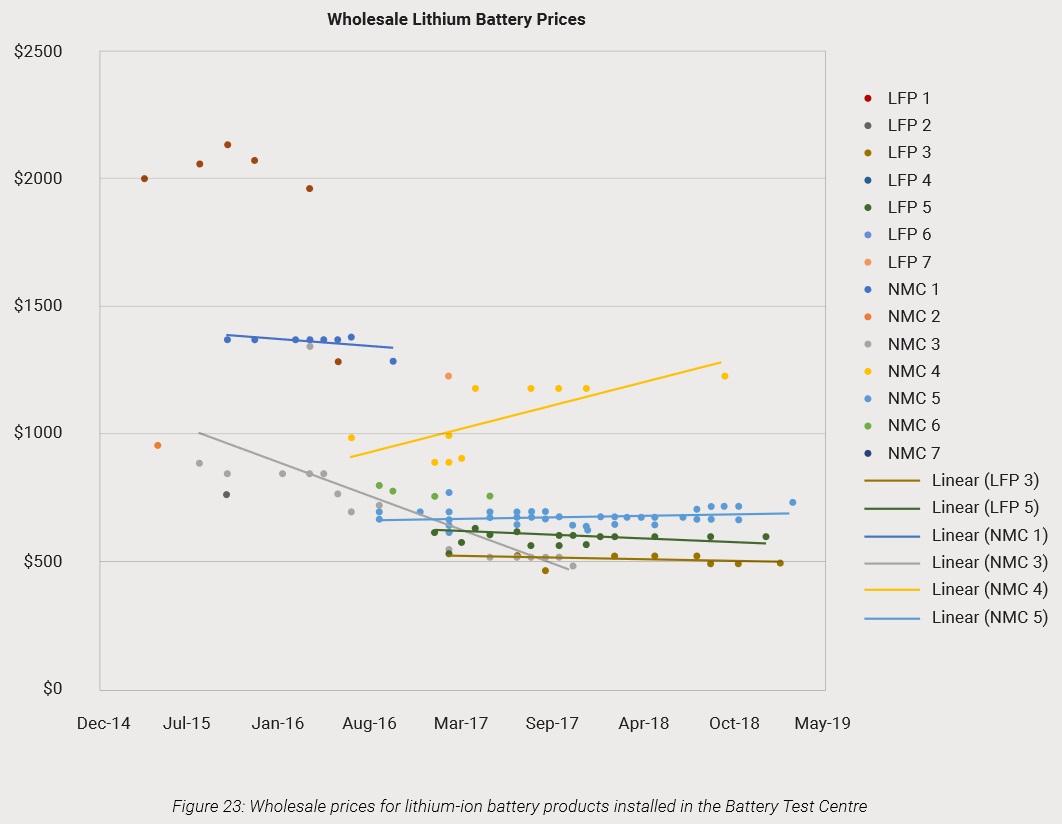

Residential Batteries Have Stopped Getting Cheaper

According to the Battery Test Centre there’s been no significant overall decrease in the cost of lithium batteries for two years. The graph below shows wholesale electricity prices for the models they tested. Unfortunately, they don’t tell us the names of the batteries for some reason. Don’t they know that giving names and prices is not illegal? We do it on our Solar Battery Comparison Table and I’ve hardly had to kill any battery assassins as a result. Note the prices on the graph below are without retailer margins or installation costs. Also, they often don’t include the cost of required supporting hardware:

Two explanations are given by the Battery Test Centre for the pause in price falls are:

- Manufacturers weren’t able to meet demand.

- The cost of raw materials — especially cobalt — increased.

Supply and demand certainly could have been a factor — it often is — but an increase in material costs isn’t a convincing explanation. It’s the sort of thing CEOs come up with when they can’t live up to their promises or need to justify a price increase.

Lithium Prices

Only a small portion of a lithium battery is lithium. Because it’s the lightest metal, a little goes a long way. This means a large increase in the price of lithium only results in a small increase in the cost of a kilowatt-hour of lithium batteries. Also, the price of lithium has been falling for a year and a half:

Cobalt Prices

The increase in the price of cobalt was more extreme:

But not all lithium batteries use cobalt and the ones that do use very little. If Tesla’s statements about the quantity of cobalt in their solar batteries can be trusted5, it puts an upper limit of around 200 grams of cobalt per kilowatt-hour.6 This means if cobalt was purchased at its peak price it would only add a maximum of around $12 per kilowatt-hour. As the estimated wholesale price of a Tesla Powerwall 2 without installation comes to $880 per kilowatt-hour, that’s only around a 1% increase. And since cobalt prices have collapsed down to around where they were two and a half years ago, even that small amount no longer applies.

Making a good residential solar battery is difficult

Personally, I think the main reason why the solar battery prices monitored by the Test Centre haven’t fallen is because making a good residential battery has turned out to be freaking difficult. If it wasn’t, their testing wouldn’t have involved so many faulty, buggy, buggered batteries.

Another reason for the hiatus in price declines was probably Tesla’s multiple price increases for the Powerwall 2. This reduced pressure on other manufacturers to reduce their prices to compete.

Finally, I think the announcement of South Australia’s large solar battery subsidy helped keep prices high. After all, why bother to lower your price when a state government is effectively going to lower it while hardly costing you a cent.7

Some good news is that, while batteries the Test Centre has investigated haven’t budged much on price, there are new arrivals on the solar battery market that are competitively priced. Our Battery Comparison Table shows what’s available. The problem is, since they haven’t trialed by the Battery Test Centre, it’s harder to be sure how well — or poorly — they’ll perform.

The Moral Is Caution

Apart from the performance of the Sony Fortelion battery and the fact round trip efficiency doesn’t deteriorate over time, there’s not a lot of good news in this battery report. I think the overall message is one of caution. Just as time doesn’t actually heal all wounds, it doesn’t necessarily improve solar battery systems either. This was demonstrated by newer Phase 2 batteries being faultier than older Phase 1 batteries.

I think the most important thing to take away from this battery report is the importance of using both an installer and a battery manufacturer you can rely on to fix problems or completely replace faulty solar battery systems as required. And keep replacing them if they have to, as Redflow did four times with their ZCell.

But many reliable solar installers are now refusing to sell batteries because they have seen how unreliable they can be. This means more battery systems are likely to be sold by dodgy installers and this means more problems for consumers. I’m sure some big manufacturers will get it right before too long and start producing highly reliable solar battery systems, but by that point the battery industry’s reputation may have suffered a lot of damage.

Footnotes

- Did you see watt I did there? Batteries — shocking? I hope you got a charge out of that. It’s one of my current jokes. ↩

- When a solar battery discharges energy equal to its nominal or nameplate capacity that is regarded as one cycle count. Many households are likely to use less than 0.6 of a Cycle Count per day because the usable amount is less and decreases over time. Also, the available stored energy won’t always be fully consumed. ↩

- Alpha ESS state this is a different battery module from what they currently use. ↩

- Additional losses will include changing energy into low voltage DC electricity batteries can accept and also from changing the low voltage DC electricity they provide into the AC electricity homes use. ↩

- Let’s just assume they’re telling the truth this time. ↩

- Tesla has said they can greatly reduce the amount of cobalt their batteries require, but I’ll use this figure from around when cobalt was at its peak price. ↩

- There are compliance costs for batteries to be part of the scheme, so it’s not quite free. ↩

RSS - Posts

RSS - Posts

I’ve never even heard of the Sony ones. None of the resellers I’ve looked at stock them

Yes, they definitely don’t seem to be a thing in Australia anymore and looking at a European price I see it’s around $1,800 a kilowatt-hour uninstalled.

The Sony Batteries were used in the Fronius Battery pack which is now not for sale.

Ronald,

I guess that Redflow doesn’t appear in any graph, due to the endlessly repeated electrolyte replacement. That’s very very frustrating, as capacity endurance is its one claim to fame. So now we’re back to relying on warranties and corporate commercial endurance. (Despite field failures) That doesn’t motivate me to pay a price premium for it.

My roof should go on in early August, so I may have to go with lead acid initially, while the fancy batteries become at least reliable, if not economical.

tsk tsk tsk……

I’d say ‘I told y’so’, but that probably wouldn’t get posted either.

onya Ron! You tellum! Since most of the recycled LA batteries are no longer available (eg ex-Telstra) y’can’t do better than decent-quality SLA-AGM battery-banks from ANY perspective, including price. (ie around $1.30 per ah with a three-year warranty…. or approximately $100 per kWh.

I’m surprised this hasn’t been brought up long ago. 😉

My thoughts also. We used the “PMG type lead acid batteries” exclusively on airports and they performed well.

Also I have a sealed lead acid battery in my caravan which serves lighting and water pumps with no major hassle. The last one in the van lasted at least 4 years, and I would expect similar performance with the latest one which has been in for over 2 years to date.

Yes, the lead acid is a bulkier unit and its discharge voltage needs monitoring closely. If I had room in my villa, I would consider lead acid for my lights, and think about expanding number of collectors, etc, for power needs.

Yep. Telstra used to replace the HUGE standby batteries even if they’d never been used. (From memory 800+ ah ~ and big as a suitcase. We used to get ’em from the disposals depot in Port Melbourne for $15 each. A friend of mine finally dumped her bank of 8 a couple of years ago, after nearly 30m years of (fairly frugal) use.

Accomodation is always a problem tahese days, but if you can find space to park ,say four SLA/AGM batteries you should find they’ll run your lights, computer, tiny-tv (mine runs on 6 watts)/cassette-player, small fridge-freezer (58-litre Engel) phone-charger and a couple of lights.(rig up modern 4/5-Watt torches to run off your battery-bank.)

I currently have two such batteries running those articles in my van where I’m temporarily living. They’re 145Ah each, and stay pretty-well fully-charged off a 250-Watt panel on the roof along with the short daily car-trips. (For the microwave and kettle I fire up the remote-start generator.)

Bought them new from a local lad for $185 each, and they come with a 3-year warranty. Six (?) months down the track

There are all sorts of options available. Y’can get me —> [email protected] 9if you want to discuss them.

Sony no longer makes the batteries in Fortelion. They are MuRata for the last few years I think.

Same exact high quality brand of Sony before the buyout from MuRata. So that hasn’t changed at all. This cell is near exactly identical to the Samsung 40T and performs near exactly the same in test except it actually runs a few degrees cooler @ 30A CDR. I highly recommend this cell to all who have very high expectations and desires from their device(s). These are 100% Legitimate and Genuine cells.

I ran the LG resu10 48 volt here and 1 of the banks has failed and blows the 200A fuse. Anyone know about repairing or diagnosing this failure, please help me! Thx. –Dave

Dave – if you are blowing a 200A fuse every time sounds like there is a short somewhere. That’s what I’d be looking for.

Yes! it is in the battery where the short is. I need some smart people from LG to help. The US rep said they can’t devote the resources. This is a sad comment to me on LG that they do not want to know the failure cause. I could care less about warranty. Very sad and in line with the Canberra results.

I think you mean the fault is in the electronics attached to the battery. Either the charger/BMS or the inverter. If there was an internal short in the battery itself it would catch fire.

I think you do not know the story here. This is why these failure are so bad.

The battery will sit disconnected from an inverter just fine. On or off. IIt is when you connect it to an inverter it blows the fuse. I have many inverters and am living offgrid.

If anyone has a connection with LG I would appreciate it .I think they may want to know about this failure. I have another LG that is fine.

Lithium Cylindrical Cells have internal short circuit protection integral to the cell architecture to prevent dangerous heat and pressure situations from developing.

This level of protection is in addition to other protection devices incorporated in battery management systems at both the cell and cell string level.

Very few battery stack integrators abandon the cell intrinsic internal short circuit protection in favour of their own protection design, except pouch cell batteries with can be safely dealt with differently in design.

Lawrence Coomber

The LG are stack cells. I have been told they can crack in a failure mode. That is why the fuse blows if any load is connected. It is similar to the old LA failure of breaking down under load.

I do not know what the problem is with my LG Resu10, and if anyone knows an LG rep I would appreciate a contact. When it failed it had 99% Sol and is currently at 58% Soc.

The other Resu 10 is fine. I am thinking I will contact the folks at Canberra. This battery model failed the LG and Schneider testing here in the US. LG needs to redesign this for higher charge and discharge current.

Hi Dave,

The RESU10 (low Voltage) battery has not been integrated nor is approved for use with the Schneider XW inverters as it does not follow the RESU batteries BMS Power Map and in start up mode has a high in rush current that can potentially blow fuses in the battery, I guess this is what is happening to your system.

In Australia the only approved LV Battery Inverter for Off Grid is the Selectronic SP Pro as it manages this with a pre charge and EMS software to treat the battery BMS data as the priority and not the AC load.

I was part of the failed test for Schneider LG and so I know quite a bit about this.

The battery fails now with zero load. Just switching on a good inverter with zero load blows the breaker. The good LG works fine on the same inverter. The bad battery powers up and runs fine as long as the inverter is not on. I have got some good contact info here and thank-you.

My opinion is LG needs to build a battery that will work offgrid! They had the closest thing to perfect I have seen yet. A good unit I use for my clients is the Discover AES LFP. It is listed for all Schneider Electric inverters and is plug and play.

When I read the recent report I came away with the impression that the BMS was sometimes not doing its job properly, allowing over-charging/over-discharging and damaging the cells. So better firmware and means of detecting the State Of Charge will be needed to improve battery reliability.

Ronald,

How did the fourth phase one battery perform? You know the lead acid one.

How does it compare generally.

cheers, great summary.

The GNB Sonnenschein PBA is still going. But it’s not tested in the same way as the lithium batteries and is cycled less often, so we can’t say it will last as long as the “good” lithium ones do. The same goes for the Ecoult UltraFlex which is the other lead-acid battery tested. It is described as an “advanced” lead-acid battery. It became faulty and had to be replaced and the replacement has developed a fault and it needs to be replaced.

Ron there is a lot more to be learned by a visit to ITP in Canberra. They are very helpful to those who visit, and I commend their openness and transparency in all things.

ITP Renewables publishes six-monthly reports which describe results to date and lessons learned.

Here are the 6 reports promulgated so far.

https://batterytestcentre.com.au/reports/

Battery Testing Report 1 – September 2016

Battery Testing Report 2 – March 2017

Battery Testing Report 3 – November 2017

Battery Testing Report 4 – March 2018

Statement on SimpliPhi Results Published in Battery Testing Report 4 – July 2018

Battery Testing Report 5 – September 2018

Battery Testing Report 6 – June 2019

Lawrence Coomber

Makes me glad my house with my 6.6kw system isn’t going to be ready until about March next year.

Hopefully WA will have subsidies out by then along with some decent batteries.

I read a report by some people who stated that with fairly meticulous care, such as mostly only using the top 10% of the power of lead acid batteries, deep cycling them periodically, equalising their charges, topping up the electrolyte and performing regular maintenance and servicing on them, their battery banks were in near new condition after 30 years. I think I have saved the article and I might be able to refind it on the web.

Shane

Lead acid battery storage designs can be very efficient, reliable, and enduring when integrated by an experienced Off Grid system designer.

Search the CEC approved Standalone PV Inverter list and you will find both single phase and 3 phase models there from 5 to 100 kw.

Importanly several of these models provide for very efficient DC Coupling PV/Batt Off Grid designs at a nominal battery voltage of 480 VDC.

Higher voltage storage systems are characterised by higher DC Battery voltage / lower DC current / small diameter cabling / lower current protection devices.

The net result being much more efficient and safer lower current circuitry for the entire DC systems, PV and Battery Systems.

Getting back to you key point Shane, yes what ages all batteries (including Lead acid) is current magnitude in both modes of operation, charging and discharging.

The best battery storage designs that will substantially extend the battery bank life, are those that exploit Ohms law to advantage, and design for lowest current designs to suit the systems design capacity and performance objectives.

Lawrence Coomber

In 1953 we were off grid. In rural Victoria, on a farm in the Howqua district.

We had a bank of lead acid batteries, and a Lister Diesel engine to charge the batteries. It was high maintenance. As a lad of 7 I was adept at starting the Lister for its daily charge, but not allowed near the acid electrolytes.

Distilled water was needed to top up the electrolytes, a constant chore for my dad, the only one allowed to do so.

We had 32 Volt appliances. They were quite sluggish – mum had a Hoover tub, and it was very underpowered compared to its 240 V version.

Lights were quite dim, but better than the Tilley Lamps and Hurricane Lanterns we had to use before electricity. Refrigeration was by Coolgardie Safes, and a Silent Knight Frig. The Frig and lights all ran on kerosene.

I woke mum and dad up at 6 am with a cup of tea, made with a methylated spirits camping stove. At the age of 7! Then got the fire in the wood stove going so we could cook breakfast.

Hot water for baths was heated in large pots on the wood stove, while a chip heater was used for showers.

Ah, the good old days, with outside one hole long drops, and newspaper squares on a nail.

Very primitive in retrospect, but great luxury after living with no electricity at all.

I remember there was a very long waiting list for the system.

hi Chris.

Been there done that – here in Bayswater, about 20 miles from the Melbourne CBD….. except for the electricity, which wasn’t within rifle-shot until we moved to Ringwood a few years later. There were no building materials available for a long time post-war, and I spent those years in a disused dairy-shed, and share many of your experiences.

Bath-night stands out. Drag the gal-iron bath-tub in front of the large open fire (in the living/only room in the dwelling) and fill it with water simmering in 5-gallon drums.

Then in went the kids (all three in one go), and after them mum, and finally dad (cos he was the grottiest). Finally the dirtiest clothes (which didn’t need careful handwashing) were done.

The indoor plumbing consisted of a hose attached to a 250-gallon tank just outside the back door. And, as you say, the dunny was down the back, and non-flushable because the hose didn’t reach that far.

Even the ‘rich’ locals weren’t much better off, but attitudes were VERY different in every aspect (including ‘neighbourliness’) and it was all made to work. Over time just about everybody could turn their hand to just about everything ~ or went without.

Little wonder, then the despairing headshaking at today’s ‘attitudes’ and unnecessary wastefulness and complications, which always ends in people selling their soul to the devil for the latest (and often pointless) thingamajig,

It’s beyond me why people would deliberately spend their lives in thrall to some ‘manufacturer’, ‘provider’ or other (alleged) ‘authority’. Once upon a time getting out from under such positions was the goal to be striven for, and the KISS principle was the guiding principle.

It was also the time when the ONE SINGLE BATTERY operated the same tractor, truck, houselight/whatever from new until the wheels fell off.

The pressure to abandon individual endeavour, whether successful or not, is crushing in from all sides, but is still more or less attainable . For now.

Haha. Chris you have some fond memories of the older DC systems looking back.

I started as a DC Power Sytems Engineer well after you (1968 to be precise) on an Aircraft Carrier HMAS Sydney. 400 VDC.

Has proved to be a very valuable grounding.

Lawrence Coomber

Ok, my problem is I want to go completely off grid yet still be able to run the house and etc no matter what the weather, I would like to have a dual system of wind & solar, now I do not want to have to rely on gas, petrol or diesel bottles gennies or otherwise. I know there has to be a way to do this, I don’t mind investing money into it because I do believe in the long run It’s the only way. I live on five ac with not alot of trees in the paddocks, but I want to utilize as much of the property for self sufficiency as possible, that includes water & we’re renovating a 1930’s weatherboard farmhouse, so ??. Not alot of cash so slowly but steadily & deep depth research. Battery storage and consistent power is what we’re talking about here! Ideas???? Help!!!! Say hi to Tonto! Nasty mutant goats, quite right to keep away from them! (look what happened in N.Z with sheep)… (please say you know that reference & I promise to laugh at the jokes) Thanks Betsy?

I’ll just give a few general points about going off-grid:

1. First, if you are going off-grid for environmental reasons – don’t. This is because it is better for the environment to stay on-grid and send your surplus clean solar energy into the grid so it will reduce fossil fuel generation. Unless your solar system is very small the feed-in tariff should more than pay for supply charges. You can still set yourself up so you can be self reliant if and when the grid goes down.

2. I have not yet seen a small wind turbine that can pay for itself. In my experience it’s always better to put your money into a larger solar/battery system.

3. If you are going off grid a small generator is a good idea, especially if you have a single point of failure such as one hybrid inverter.

betsy hughes

Of course you have options to achieve precisely what you want reliably, efficiently and importantly, cost effectively. No if’s – no but’s.

Contact me anytime and I will be happy to fill you in on the details.

Lawrence Coomber

Betsy Hughes (Goat proof Off Grid Installations?)

Your comment about “mutant goats” took me back a bit Betsy to an Off Grid System we installed on a goat farm in 2011/12 in rural Queensland.

We worked in “cooperation with over 300 goats” roaming free in the install paddock. I made an engineering decision that it would be impossible for a goat to climb up onto slippery solar panels at 25 degrees inclination.

I was proved wrong!

http://www.aquilapower.com/offgridimages.html

Lawrence Coomber

Goats getting up there does not surprise me at all. Here is a BBC clip of some crazy goats:

(While the goats look kind of cute, I’d still be wary as one of them could be a Mutant Star Goat in disguise.)

Thanks Lawrence, I will after I have a sit down with the hubby we’ll get in touch. By the way my dad was a Laurence, how’s that for a coincidence? Thanks Betsy

I have a Schneider XW 8548 inverter with 12KW of panels. Can you suggest the optimum Battery Solution for an Off Grid System. Open to suggestions, The more I read about the Lithium storage the more i worry. Is the AGM or Gel solutions the better way to go. ATM I have 39 NiFe 300ah batteries which I am not satisfied with. I need a storage system that the Schneider Inverter and MPPT 600/80 supports.

The batteries I would look at are Zenaji (Lithium Titanate) and Redflow ZBM (Zinc Bromide). The Zenaji is a bit expensive, but warranted for a long life. My brother has had them running for half a year now, and the high allowable rate of charge/discharge allows them to grab more of what a large array can deliver. (He has 19 kW). The Generation 3 Redflow ZBM is just out, re-engineered for more economical mass production, through rationalisation and modernisation. It looks to me incrementally better than the older generation in many areas. (Check Simon Hackett’s blog) It should also be cheaper, as economy of manufacture is claimed. You’d need at least two, though, as the allowable charge/discharge rate of one is only around 3 kW or so, as far as I recall. Either type should be a durable solution. I can’t help comparing plain Lithium Ion with my mobile battery – a dwindling resource.

Each battery will, however, be warranted only with a known compatible inverter & charger combination. Seeking a battery compatible with an old inverter is a suboptimal strategy, I expect. I’d try that first, then adapt the strategy as needs must. Off-grid performance is battery-dependent, unless you have a generator, even a little 3 kW one. It can charge a battery bank for a longer time, then the battery can support a welder or whatever in extended very dull/rainy weather.

As for a 480 Vdc battery bank, this electrical engineer would be terrified of the lethality of that voltage in DC. (But then, having moved over to electronics long ago, for a lower voltage life, maybe I’m just cautious.) The off-grid installation I’m putting in place as soon as current building efforts complete, will be ELV. OK, 48v is the minimum worth considering, and higher would be more efficient for high power inverters, as every kW is a little over 20A at 48v, and resistive losses climb with the square of the current. And even 96 Vdc is seriously more lethal then 48v, so it may just be a matter of locked cabinets, and a minimum of exposed busbars when the door’s open.

If considering Lead Acid, I’d look at the SolarQuotes blog on the new safety requirements.

Hi Douglas:

If you are looking for an Off Grid PV solution, you have started with the wrong Inverter. The 8548 is a Hybrid Inverter, and not a fully featured Standalone PV Inverter.

The design and functionality differences between these two inverter types are poles apart.

Hybrid Inverters are designed principally as On Grid Inverters with a rudimentary only Backup Power functionality in the absence of the prime power source (the Grid). Also the key design features that allow higher voltage DC coupling of solar PV and battery storage stacks at LV voltages (up to 1500 VDC) are not features of Hybrid Inverters which operate at lower DC battery bus voltages in the ELV range (up to 120 VDC and typically 48 VDC).

Off Grid Standalone Inverters are the appropriate choice for those circumstances where no access to the Grid is required and Off Grid becomes the preferred option. What is your situation regarding a Grid source Douglas?

I mention this point up front because you stressed you wanted an “optimum Battery Solution for an Off Grid System”, and this simply cannot be achieved with your Hybrid inverter choice.

Addressing battery storage stack designs: If your preferred battery stack chemistry is Lead Acid rather than other chemistries, this is a very good choice for Off Grid PV solutions, and in particular at a nominal battery stack bus voltage of 480 VDC, which provides for optimal system efficiency; system safety and long battery life. You still need to select the right type of LA battery though fit for the purpose.

So what makes the 480 VDC nominal voltage battery stack and Solar PV DC coupled solutions so superior? Quite simply higher voltage underpins the power systems overall functionality, efficiency, safety, and importantly battery life; and this is all made understandable by the immutable Ohms law, and by extension power equations including P = V x I.

As an example between the two system types of Battery Stack (1) ELV stack @ 48 VDC and (2) LV stack @ 480 VDC, servicing an overnight load demand of example 0.96 kW average, the following power equations apply to these system designs:

(1) ELV Battery String Current at 960 (W) = 48 V x 20.00 A (String Current)

(2) LV battery String Current at 960 (W) = 480 V x 2.00 A (String Current)

The ELV Battery String Current is 1000% that of the LV String Current. This is a critical issue regarding both performance, safety, longevity and copper losses and overall system hardware costs.

Battery stack (2) @ 480 V) will outlast stack (1) @ 48 V in multiples, all other factors being similar. The key take away is that battery aging is a function of and directly related to string current for both charging and discharging. Battery temperature is also related directly to battery string current, and there are other factors that contribute to battery stack aging, but these factors are mainly influenced by and symptomatic of string current also.

Many power engineers and certainly most electrical technicians would not be experienced or formally qualified in optimum battery stack design engineering, across all chemistries and therefore not able to speak with authority on this subject naturally enough, but one thing all people involved in the industry should be able to identify with, is that Higher DC Voltage Battery bus sources equate to Lower Battery String current, which means lighter gauge DC wiring; smaller rated circuit protection devices fuses and circuit breakers; less heat losses; much higher system safety; and importantly in Solar/Battery DC coupled systems, no inefficient DC-AC-DC power conversions as is the case in AC coupled system designs.

As a power engineer for many years now and having worked in Detroit US and in China with high voltage battery stack design for EVs over the years; I have experienced and worked through the transitional battery storage voltages of 12 – 24 – 48 VDC to 960 VDC and beyond and continuing.

Discussions by innovators at the moment are taking us in the right direction regarding Storage System Voltages and thus power density and capacity and importantly new chemistries, and do not be at all surprised that storage sources (at the base level before internal system conversions] will exceed 30 kV. A level that makes possible almost instantaneous incremental inductive high speed storage charging.

A better (480 + VDC) storage solution though with superior electrical attributes and in particular longevity is one using Ultra-Cap Energy Storage stacks either alone, or in conjunction with a LA battery stack for example.

You might be hard pressed in finding qualified power engineers or manufacturers in Australia though with firsthand experience and expertise to discuss these types of designs, which are in common use elsewhere.

I hope some of the points above are useful to you Douglas as you continue deliberating and moving forward with your system design.

Lawrence Coomber

If you are looking for an Off Grid PV solution, you have started with the wrong Inverter. The 8548 is a Hybrid Inverter, and not a fully featured Standalone PV Inverter.

The design and functionality differences between these two inverter types are poles apart.

Thank you for the response Lawrence,

Before we go further into this can we confirm that I do have a stand alone inverter or at least one that is capable of Off Grid and the configuration support for most battery types. recently Schneider did discontinue the WX 8548 model and brought in the Hybrid unit in place of the model I bought two years ago. I have been using it for that time with no issues using NiFe batteries, which are a challenge for this inverter with 64V max support for the gen. 39 cells require a few volts more to get to bulk. Anyway I can live with that as the gen comes on and can at least charge to 64 V. The MPPT do support the charging of the NiFe oddly. Things were OK until I wanted to add a couple of cells. Saying that, were you aware of this model ?

Hi Douglas.

My comment was a technical generalisation relating to your key point of an “optimum Battery Solution for an Off Grid System”; which is not what you have, nor can that be achieved with your current power plant system hardware configuration.

Back to the practical matter of what you have in front of you to work with though: and yes you have configured the hardware about as best as possible; it works OK; so you should stick with that.

For a low cost improvement down the track though you could consider rearranging the Solar PV bus so your battery stack capacity can be increased and work more efficiently in a DC coupled design.

Learn more about Solar PV bus designs Douglas and this open up some system design options for you to explore. A Solar PV module due to its intrinsic equivalent circuit electrical attributes, is both a variable voltage power source [by adding/subtracting PV modules in a string configuration] and a current limiting circuit device [learn about Solar PV IV curves].

Importantly a Solar PV bus can also have multiple DC outputs [taps] that can be exploited in system design for such ancillaries as battery stack(s) DC coupling; variable frequency drives [pumps and motors]; other energy storage DC sub-circuits such as water heaters and many other duty cycle and sensor controlled DC circuit functions, as well as multiple DC-AC conversion devices [such as general single phase sub-circuits and ‘specific equipment 3 phase circuits’] etc.

A fully featured system overall design depends entirely on what is fit for purpose, for the customers specification.

It is obvious though, that power systems design engineers have a limited role to play in On Grid power systems design at the customer install level, as Grid connectivity is a heavily regulated customer/grid network relationship, where the grid network quite appropriately for customers set the rules of engagement.

Standalone design engineers have a completely different and much more expansive toolbox to work with though as there is only one customer specification to design for.

You still have not mentioned specifically if you are a Standalone or an On-Grid customer though. And due to the critical regard to inverter input/output functional isolation, there is no such concept in a single system design as being both. I think you might be an On-Grid customer with a system that provides for ‘secondary backup capability’ from a battery storage unit.

All the best with your system Douglas.

Lawrence Coomber

Hi Lawrence,

We are 100% Off GRID household here. Looking at the Zenaji product here in Australia very interesting product. Do you know of it?

No I dont know it Douglas but if you email me a specification I will have a look at it and respond back if you want.

Lawrence Coomber

Lawrence,

to confirm: From Schneider support…

Hi Douglas,

The Conext XW+ 8548 can be used as stand-alone with no Grid connection or with the Grid attached if installed prior to the CEC certification running out which was on the 21 Jan 2020. After that date the XW Pro 8548 replaced the XW+ 8548.

The Conext XW+ has been designed for off-grid Stand-Alone operation and does not need to have the grid connected for it to operate correctly and provide power to the loads. It does however need a battery bank connected to the DC input to operate.

So we have the correct inverter Lawrence.

Great- your all good to go Douglas.

Lawrence Coomber

Thanks for that advice Erik. I contacted Zenaji and will most likely go down that road. My concern about any battery I suppose is the discharge cycles and how to configure the Batteries to suit. Using XW 8548 Schneider they want you to have a specific minimal battery KW and then you should be cycling a few times a day to maintain the warranty from Zenaji.

Douglas, I’d wave the specs for your MPPT at Zenaji, to confirm it won’t over or under charge the batteries. It’s the charger which is configured to suit, as each chemistry has its tolerances, and compatibility is key. (At worst, a new MPPT would be a tolerable system rejig for going off-grid, I figure.)

My understanding of Zenajis is limited to reading the specs some months ago, and listening to my brother’s reports on his recently installed system, but I don’t recall any minimal daily cycling requirement – just a claim that they would last so many years even if you cycle them more than once per day. (It is the Redflow ZBM which must be totally discharged at least once per fortnight or so, in order to maintain its capacity over a long life.)

Reading their warranty exclusions, again some months ago, I saw that there is a lifetime warranty reduction of a couple of days for each day the batteries are operated above a temperature limit, and the default arbiter is the weather reported for your locality, day by day over the years. I plan to install the batteries indoors, where it is substantially cooler on a hot day, and perhaps record temperature. I think there is a SolarQuotes blog page on the subject, with a link to the warranty, if memory serves. (Ronald?)

Again, the most important battery warranty issue would be charger compatibilty.

And, yes, for a particular inverter power rating, there will be a minimum battery sizing to provide sufficient discharge capacity to support it. The high discharge rating for Zenaji would allow you to get away with a smaller battery than for many other chemistries, but that would reduce the energy reserve needed for a day or two of inclement weather, something I don’t plan to endure off-grid. (Though keeping the old Honda generator avoids the need to go over the top with extra batteries for three bad days. It seems that rain is worse for PV generation than is medium overcast, and global warming has to mean more evaporation, and so more rain?.)

One thing my brother did was make the installer demonstrate off-grid capability by throwing the main grid-connect circuit breaker, before making the final payment. But then, he’s still just thinking about going off-grid. (The grid is still the cheapest battery, especially with FIT.)

He did initially have an issue with the battery breaker disconnecting sometimes when charging them from his generator, but the installer was on to that last I heard. (I’d have to agree with Finn’s words on the worth of a good installer. )

Erik,

Looks like I have a good design then in the Aeon battery with Schneider XW series. I’ll go with 5 Batteries to start with.

The temperature requirements are towards the end of the battery’s warranty:

https://zenaji.com/wp-content/uploads/2021/04/Zenaji-Warranty_20210408.pdf

In extreme temperatures a single use of the battery can reduce the warranty by 10 days so in a poor location it can result in a major reduction in warranty length. But in a mildly temperature controlled location the warranty is a long 20 years.

The Zenaji Eternity Battery offers a robust 20-year warranty or 22,000 cycles, whichever comes first, when operated under ideal temperature conditions between +5°C and +35°C.

While the battery is designed to function across a wide temperature range from -40°C to +60°C, using it in extreme conditions such as below -10°C or above +45°C can significantly shorten the warranty.

Each day of use in these extreme temperatures can reduce the time-based warranty by up to 10 days and the cycle warranty by up to 10 cycles. Therefore, location and installation environment play a crucial role in maintaining the full duration of the warranty.

Understood,

I will be mounting these batteries inside the garage.

Schneider XWP is designed to run closed loop charging with the right battery! You should drop me a line or replay here if you are still looking!

What do you mean ? Which battery is the right battery to use with the XW 8548+

Not sure what the other comment was but XW is completely flexible AC or DC coupled. You just enter the data that the battery manufacture specs out! This is open loop charging. Been doing this 100’s of times since XW came out in 2006 for my Offgrid Business.

When I say closed loop charging, I am speaking of the internal XW charger, its DC Mppt’s and AC coupling from a grid inverter. What I am saying is that the battery BMS controlls all of the setpoints and gets Soc data out to it’s local Insight monitor or any where in the world with Insight cloud. The batteries I use on this side of the Pond are Discover AES and Fortress E flex.

They are UL9540 certified. On one of them all I do is enter the time and date and everything is configured. The other needs a bit more but not much. These two batts BMS, are allowed to get into the XW system and optimize and protect power use safely! Clear as mud right? I know a few guys on your side of the pond who do Schneider but do not want to give their names here unless it is permitted? Is this DIY?

Here is the Austrailia link form Schneider.

https://solar.schneider-electric.com/schneider-electric-solar-expands-into-australian-on-grid-residential-solar-with-the-xw-pro-offering-reliable-home-backup-power-solution/

What Dave means Douglas is that the XWP is a highly prescriptive inverter and inflexible about the specification of the connected battery stack.

Rather than being capable of working in a DC coupled configuration with any type of suitable battery stack [i.e. where the Battery Capacity (AHr) is able to be charged fully by the installed Solar Array (kW) via a full function DC Coupled Charge Controller] and installed external to the inverter being the best choice for flexibility and functionality.

Inverters are being designed to manage many functions beyond the original inverter focus which was ‘best practice design’ in power conversion technology.

They now incorporate monitoring and communications, and also battery stack charging. The interdependencies on the inverter logic control; expanded circuit footprint, and more complex functionality to manage all of these functions (to ‘worlds best practice design and functionality’) is not possible, and they fail miserably in practice; hence the sort of reviews coming out of Labs like Canberra Battery Test Centre for the sixth consecutive year!

Finn shares my long held views that third party monitoring and communications functionality belongs outside of inverters and is the product of dedicated specialist manufacturers of ‘sensor and transducer, monitoring and control, and communications’ equipment.

And the same thinking therefore should be applied to third party manufacturers of versatile ‘battery stack DC coupling; management; and control equipment’.

Third party technology developers encourage worlds best practice competition for specific technologies, that are flexible and fully featured in application rather than generic to one at a time inverter standards.

Lawrence Coomber

Hi Lawrence,

I hope I’m not too far away from your way of thinking here. I do agree that the all-in-one inverter/charger/monitoring solutions would be inferior to a stand alone MPPT charger such as the Schneider MPPT 600/80 and the OFF Grid model of the XW 8548 unit which is core based rather than a software based inverter. The comm’s are centralised in a separate Com Box device on the network all being a component based system that can charge the battery solution supported by the manufacturer. I do not have the XWP model.

Also look at the mppt-100A -600v with an XWP all networked. 8 KW of solar for each one. The combox has been obsolete for 2 years now. It is replaced with Insight Home and Insight facility for large systems. All networked and in my opinion the best built inverter since the department of defense grant here was won by it in 2005. An 80 pound toroid transformer low frequency design for incredible surge and stability. Convection cooled for fan failures which never happen. An air channel cooling that does not blow dust on the electrical components. An engineering success from 16 years ago. Hard to beat it! I am looking all the time for something better for Offgrid!

Good comments David and Douglas.

I will sign off with this comment:

The Conext XW+ series specification sheet explains the very limited scope of flexibility regarding integrated battery stacks, and the only parameter that is remotely flexible is the obvious one being the sizing of the PV array which must be sized to the battery stack capacity, to a maximum of 10000 AHr.

Important is that the Conext XW is not a Standalone [Off Grid] Inverter with DC Coupling functionality which is an important functional and exploitable in design characteristic of Standalone Inverters.

It is a hybrid inverter, and the charging solution is not a DC coupled one as evidenced by the specification entry regarding Power Factor Corrected Charging = 0.98. In a DC coupled charging circuit the power factor is always 1.0 and can never be anything but 1.0. Power factor is defined as the cosine of the angle between the voltage phasor and current phasor in an AC circuit.

More importantly is the Battery Stack Voltage being prescriptively ELV [nominal 48 VDC]. There is no flexibility in this important system design parameter whatsoever.

Modern LV Standalone [Off Grid] and DC Microgrid Systems designs are those that provide system designers with much more latitude than the prescriptive parameters outlined in the XW+ Series specification.

The whole point of technical forums is information exchange and not limit it to “what the current stuff around might be” because everything around at any point of time in the electro technology sector is obsolescent as soon as it hits the shelves.

Technologies evolve and morph and the two big ticket parameters regarding battery storage and inverters in the design companies at the moment follow on from EV stack designs in the LV [up to 1000 VDC] and dc coupled inputs.

LV ICs [FETs etc] are commonplace today in these DC circuits. With this shift in design, comes equipment safety [higher voltage means lower charging and discharging current] which means lighter gauge wiring and more compact and safe circuit protection devices [circuit breakers; fuses and switchgear etc]. And it follows that LV Solutions are much more economical to design and manufacture and battery life is extended multiple times over ELV Storage Solutions due to magnitudes lower charging and discharging currents.

Remember: current [both directions] is the single most critical chemical/electrical phenomena that ages battery stacks. There are no ifs or buts around this point. Do your Ohms Law maths on an ELV 48 VDC battery stack, verses an LV 480 VDC battery stack? The currents are ratio metric between the two system types; that means the ELV battery currents at any point in time are 10 times greater than the LV battery currents under the same sub-circuits loads? Goodbye in quick time battery stack.

So it is well worth injecting this view into the mix because that is what is happening, and technology evolution is not optional just because a manufacturer might talk up something that runs counter to newer principles and trends.

Lawrence Coomber

If XW is not stand-alone, how have I been living offgrid with it since 2006? And before that back to 1993 with the pre-Schneider inverters from Xantrex and Trace?

We are agreeing to not agree LC, and that is fine.

Please to the OP, you are fine with what you have no matter if you are offgrid, on grid, or in a back-up mode! You made a great choice!

The Conext XW+ Series is listed as an approved inverter with the CEC Dave. Here is the listing:-

Multiple Mode Inverter – Other Energy Source

MODEL NUMBER

XW+ 7048 E

MODEL NUMBER CERTIFICATE NUMBER SERIES TYPE APPROVAL DATE EXPIRY DATE NUMBER OF PHASES RATED AC OUTPUT (VA) TESTED TO IEC 62116 TESTED TO IEC 62619

XW+ 7048 E SAA142671 Conext XW+ 30/11/2016 03/11/2021

It is not an Standalone PV Inverter [Isolated Inverter] regarding Solar PV DC Inputs

Hi Dave,

For the last 2 years I’ve used Schneider inverters starting with the SW 4Kw unit which only supported 12 and 24 VDC then upgrading to the XW which supported 48Vdc. At the time did not even realise there were 480VDC inverters out there. Still can’t find one here in Oz.

OK so the DC is definately not DC isolated. I can see that. Not a big deal to me or my clients. Why is this improtant to you LC.

My XW does not standalone either, there is another XW and a CSW on the wall for my clients to borrow if they need them?

DG, LG RESU10H is a high voltage battery that does 400vdc. We would never want that for offgrid. 48vdc is the way to go for many reasons.

Douglas the main reason behind the ELV 48 VDC battery storage technology standard bottleneck, still dominating the mainstream market after 70+ years, is an historical one mainly not a technological one.

And with that, battery storage integrators struggle to create a compelling business case to take LV storage solutions products forward to the global small scale renewable systems industry at large, with the exception of the EV industry of course which has to only arrange for delivery of a compact integrated LV > 480 VDC battery storage product, and the customer drives off into the sunset and that is it.

The power consumer is a very different case. Contrast the EV scenario from a consumer and manufacturers perspective, against the Solar PV + storage customer.

ELV 48 VDC power electrics sprung from the Global Telecoms Industry over 75 years ago, principally because anybody and everybody is legally entitled to work with power plant generation and equipment including storage under 50 VDC. No formal licencing is required in any Australian state for ELV work. The Telecoms industry was staffed with un-licenced workers with no electrical qualifications being required. This created a great market opportunity when you have a captive audience of un-licenced and unskilled people wanting to try their hand at DIY power plant solutions.

I recall fondly the mid 60’s where the good folk at Nimbin NSW started the Australian ELV DIY Off-Grid industry, and it has not changed much since.

Go beyond ELV though and anybody involved in storage needs to have an Electricians Licence as a minimum, and moving up the LV scale requires more qualifications and endorsements than an electrical licence alone.

LV Battery Stack design and build, requires specialist formal skills in Advanced Power System Engineering and also Safe Handling Design and Build LV Battery Stack qualifications. There is no such targeted training available off the shelf in Australia; and overseas qualifications and training [mainly through universities closely aligned with the EV industry in Detroit US]: and those qualifications do not come cheaply and are better suited to qualified electrical engineers not electricians.

As an apprentice electrician myself in the 60’s and later an Electrical Engineer, my trade training was centred around LV 400+ VDC technologies and cutting edge DC systems and machines on Naval Aircraft Carriers and Weapons Systems, which prepared me to easily transition into the LV EV battery technology and LV inverter design and manufacture sector over the last 15 years.

There are many more parts to the ELV to LV renewable energy trend story.

The interesting point though is that LV battery science has always made fundamental electrical science sense, but practical market driven imperatives did, as they always must, take precedence over theory, no matter how compelling the theoretical arguments are.

Australia needs to step up though and educate and upskill young Australian technology design engineers of the future if we are to have any involvement at all in the booming modern technology world, that has unfortunately already left us wafting around in others wake, and the yawning skills gap is widening rapidly.

Lawrence Coomber

Lawrence

Thank you again for your valuable insights. I agree the residential and commercial solar markets here are somewhat hamstrung to distributors who will offer support to their products. Trying new technologies is a tempting fate here, very expensive if it goes south on you, never mind your biz cred out the window. I tend to continue with a solution even if it is proprietry if the support and demand is there. Price is the biggest influencer in every market, no one wants to spend all their time going underwater quoting the BEST solution and never getting work because of it. The 480 VDC storage devices you speak of can be maintained and installed in Military installations and they have our money to throw at it too. I wouldn’t feel to comfortable with a high voltage solution in the garage myself. I love the space and will keep learning where I can.