We’re well into the first month of 2025, but before getting carried away by the fact we’re now obviously living in the future, I thought it would be a good idea to look back at which solar panels tested well last year, according to the Kiwa PVEL 2024 PV Module Reliability Scorecard.

Scorecard results are determined by meticulously torturing solar panels via a series of fiendish tests to see which survive with minimal deterioration. If a panel passes all 7 of their main tests — or even just most of them — you can be very confident it’s extremely reliable. I will briefly outline the tests and then tell you which four panels were absolute champions and passed them all. I’ll then tell you which 18 panels did nearly as well and passed the 6 most important tests for rooftop solar.

But before I do this, I’m going to give you some caveats, provisos, and flat-out excuses.

Only Good Panels Are Revealed — Not Bad Ones

If you want to check out the 2024 Module Reliability Scorecard results yourself, it’s all right here. But I’ll warn you there are limitations to what can be concluded from the Scorecard results, due to the following three conditions:

- Kiwa PVEL only reveals which panels passed their tests.

- They don’t say which panels were tested but failed.

- They don’t say whether or not a panel was tested at all.

This means that if a panel passes all 7 of their main tests — or just the first 6 — you can be confident it’s an extremely reliable panel that will last decades on a roof.

But if a panel passes only 1 test, or none, we have no way of knowing if it failed tests or simply wasn’t tested at all. This means we can’t say any panel is bad. For all we know, a panel that passed only 1 test is just as good, or even better, than a panel that passed all 7.

Manufacturers have to pay for each test, so there’s going to be a lot of untested panels out there. The only way around this problem is to pay for the full report — and promise not to publish the results.

You might also think they’d prominently display which panels passed all their tests, or nearly all, in the information they do give, but that’s not actually the case. You have to sift through the results to get that info. But don’t worry, I’ve got you covered. I’ll tell you exactly which panels did well… right after I’m done mocking the Dutch.

Kiwa’s Business Is Based On Trust – Despite Being Dutch

Kiwa is a certification company that does testing, inspecting, consulting, training, and certificating across a wide range of areas. Their company motto is “We create trust around the world.” This must be difficult to do, given they’re Dutch.

But then, the Dutch are devilishly handsome, so I suppose that would help.

The “PVEL” part of Kiwa PVEL stands for PV Evolution Labs, and is the part of the company involved in testing and certifying solar panels. They take their job very seriously. One example of this is how they send inspectors to factories to ensure the Bill of Materials (BOM), which lists what the panel is made from, is adhered to. Then they select random panels so they can be sure the ones tested are representative of what’s produced.

If you’re wondering how you can ensure the panels you get are made with an appropriate BOM and cheap materials aren’t substituted, well, you can’t. There’s no way you can realistically access the quality of components or send your own agents to ninja-like track panel production. But what you can do is use panels from a manufacturer that has spent years building a good reputation, because they’re not going to want to ruin it by selling shoddy products. A good warranty also helps, but only if it’s from an established company that’s likely to still be around in the future.

I’ll now tell you which panels did well in the 2024 Scorecard tests… right after I get through telling you about these tests.

7 Main Tests

Kiwa PVEL performs a range of different tests, but there are 7 main ones used for their Scorecard results. These tests are meant to simulate decades of exposure to harsh conditions. Below are the names of the tests, followed by what I think they should be called, along with a quick description:

Thermal Cycling — “The Katy Perry Hot & Cold Test”: Panels are cooled to -40ºC and raised to 85ºC. This is repeated 600 times. Different materials expand and contract at different rates as their temperature changes and this can weaken the bonds between them and slowly cause panels to deteriorate. To pass, a panel must suffer less than a 2% reduction in output. Doing well on this is important for panels used in the outback, where hot days and cold nights result in wide temperature variations.

Damp Heat — “The Hot & Sweaty Test”: Panels are baked at 85ºC and 85% humidity for 2,000 hours. Hot humid weather can cause bonds between materials to weaken. In extreme cases, panels taking this test have completely fallen apart. Passing requires less than 2% deterioration in output. This is an important test to pass for any panels installed in tropical or subtropical regions.

Mechanical Test Sequence — “The Bendy Flexy Test”: Wind can cause panels to flex. This is normally mild, but can gradually degrade panels. This test involves placing a load of 183.5kg per square meter on the panel for an extended time and then placing a load of 102kg per square metre on it, removing it, and then putting it back — repeated 1,000 times. A typical 440 watt panel is 2 square meters, so this test would be like having the world’s heaviest sumo wrestler and his dog sleeping on it, followed by a sumo wrestler who is merely enormous sitting on it 1,000 times. Passing this test requires an output loss of less than 2% and is important for panels that will be installed under windy conditions or under sumo wrestlers.

Hail Stress Sequence — “Whacking Resistance”: This test pounds panels with artificial hail until their glass cracks. The larger the hailstone size they can be battered with before breaking, the better. Panels with glass fronts and plastic backsheets were, on average, much more resistant than dual glass panels with glass on the front and back. Of the tested panels, only 40% of those with plastic backsheets broke when pounded by 50mm hail, while 89% of double glass ones failed. This doesn’t mean dual glass panels can’t be hail resistant, but obviously, fewer of those tested were. To pass, panels had to survive at least 35mm hail, with more resistant panels withstanding larger hailstones of up to 50mm.

Potential Induced Degradation — “The Hot & Sweaty Power test”: Potential Induced Degradation or PID is caused by various types of unpleasant electrochemistry occurring in panels. It’s normally only a serious problem in hot and humid conditions. The test starts by placing panels in an environment identical to the Damp Heat test for 200 hours. After that, as much power as they’re rated for is passed through them for an extended time. To pass, they need to suffer less than 2% degradation. If the panels are to be installed in Darwin or Townsville, you’ll definitely want them to do well on this test.

Light Induced Degradation (LID) and Light & Elevated Temperature Induced Degradation (LETID) — “The Sunny Hot test”: So far, I’ve mentioned how panels can be degraded by temperature change, hot and humid conditions, flexing from the wind, hail, and nasty electrochemistry. But now I’m going to cover the most stupid form of degradation. Solar panels can be degraded by light. While this seems like a major drawback for a device designed to turn sunlight into electrical energy, it’s actually not that bad. In susceptible panels, LID can reduce output by 1-2% after the first few days in the sun — but then it stops. LETID affects some types of PERC panels and requires much more time to take effect. Fortunately, good manufacturers have mostly gotten on top of these problems, so they’re no longer the issues they used to be. The test exposes panels to bright light and heat and to pass they must suffer less than 1% decline in output. Of the panels tested, 96% passed.

PAN Performance — “The Not Really Rooftop Reality test”: This test is designed to measure how well a panel performs under real-world conditions, but it’s designed for panels used in solar farms, not on roofs. If a panel passes this test it’s a good sign, but it’s the least important test when considering panels for residential use.

Here we see the Dutch making solar panel stew. I tell you, these people will casserole anything!

Now I’ve described the tests to you, I’ll tell you which panels passed the tests… as soon as I’m done telling you how I’ll tell you panels passed the tests.

Scorecard 2024 Top Performers

First I will tell you the 4 panels that passed all 7 scorecard tests — including the not 100% relevant PAN Performance test. After that I’ll list the 18 panels that passed the 6 main tests, but not PAN Performance. This gives a total of 22 Champion panels.

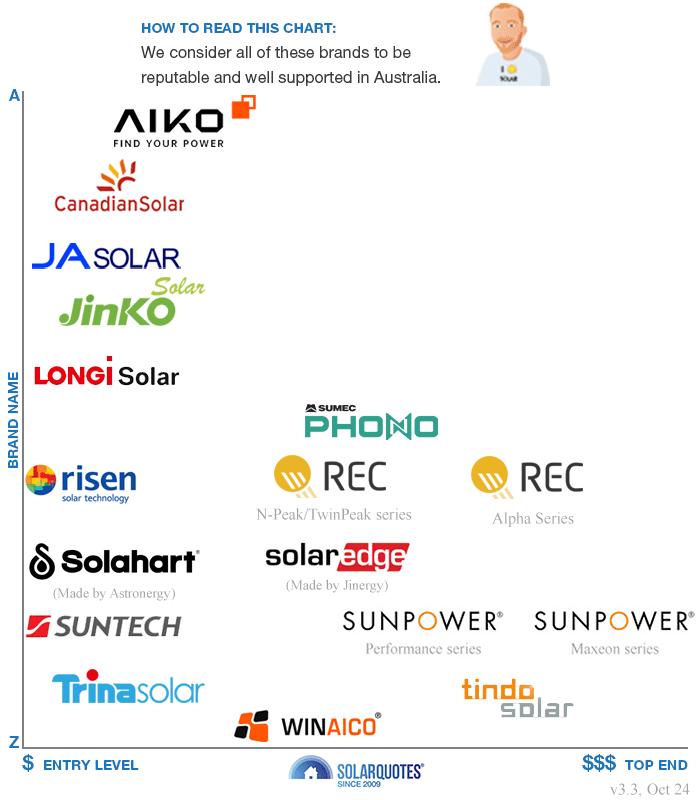

The 22 champions are from 11 different manufacturers. Three are from manufacturers we currently recommend:

You can find the above chart in our Solar 101: Buying Solar Power guide, where it’s kept up-to-date. I’ve put the panels from manufacturers we recommend first. All the other manufacturers have little or no presence in Australia and I’ve simply put them in alphabetical order. I will mention there are a lot of Indian panels now passing plenty of tests, so the days of China being massively dominant in panel manufacture may be limited.

For all the panels that did well, I first give the name of the manufacturer, followed by the panel model designation which is a string of letters and numbers. Because the wattage of panels can vary, this is represented by three hash marks — “###”. In the Scorecard Report, they use the letter “x” instead, but I’ve learned through hard experience not to put the letters triple x in blog posts.

Then I give the size of hail the panel was able to resist without breaking and whether the panels are bifacial or monofacial. Most are bifacial with glass on the front and back and able to use light from either direction. While they can use light from behind, they’re still suitable for normal rooftop installation. The monofacial panels have glass on the front and a plastic backsheet. Finally, I give the location of the factory where they were made, plus a little relevant information.

I’ll now tell you which panels passed all – or nearly all – of the tests… for real this time!

2024 Scorecard Champions — Passed All 7 Tests!

The 4 champion panels that passed everything, including the PAN Performance test, were:

- Trina Solar: TSM-###NEG21C.20, Hail resistance: 40mm, Bifacial, Manufactured in Changzhou, China. Trina Solar is a giant solar panel manufacturer that has been around for 28 years. They’re on SolarQuotes recommended panel chart, and here’s the datasheet for this panel. Unfortunately, it only has a 12-year product warranty instead of the 25 or 30 years I normally recommend — but it’s still likely to last a long time.

- EMMVEE: E###HCBG144, Hail Resistance: 40mm, Bifacial, Manufactured in Bangalore, India. While this Indian manufacturer can clearly make a good panel, I’ve never seen them in Australia.

- NE Solar: NESE###-72MHB-M10, Hail resistance: 40mm, Bifacial, Manufacturered in either Phnom Penh, Cambodia or Kota Batam, Indonesia. NE Solar’s headquarters are in Phoenix, USA. As far as I know, this company has no presence in Australia.

- SEG Solar: SEG-###-BTC-BG, Hail resistance: 40mm, Bifacial, Manufactured in Yancheng or Changzhou, China. This manufacturer has their headquarters in Texas, USA. While this is clearly a good panel, it’s not something I’ve seen Down Under.

2024 Scorecard Pretty Much Also Champions — Passed The 6 Most Important Tests!

The following 18 panels passed the 6 most important tests. I consider them basically on the same level as those that passed all 7.

- AIKO: AIKO-A###-MAH54Mb, AIKO-A###-MAH54Mw, AIKO-A###-MAH72Mw, Hail resistance: 50mm, Monofacial glass/plastic backsheet, Manufactured in either Guangdong or Foshan, China. AIKO panels are on our recommended chart and known for high efficiency and their ability to handle the effects of shade. These particular panels are currently available throughout Australia and have 25 year product warranties.

- JA Solar: JAM54S30-###/MB, JAM54S31-###/MB, Hail resistance: 50mm, bifacial, manufactured in either Yangzhou or Shanghai, China. JA Solar has been around for 20 years and is on our recommended chart.

- EMMVEE: E###HCBG108, E###HCBG120, E###HCBG132, Hail Resistance: 40mm, bifacial, manufactured in Bangalore, India. As mentioned above, I haven’t seen Emmvee panels in Australia.

- Imperial Star: ISM7-SHDD108-###/M, ISM7-SHDD108-###/M, Hail resistance: 50mm, monofacial glass/plastic backsheet, manufactured in Kampong Speu or Phom Phen, Cambodia. This company manufactures in Cambodia but has its headquarters in California. I haven’t seen them in Australia.

- Meyer Burger: MB-B120A1B_###, Hail resistance: 50MM, monofacial glass/plastic backsheet, manufactured in either Freberg, Germany or Gwatt, Switzerland. Meyer Burger is a small manufacturer of high quality panels that may not be aware Australia exists.

- NE Solar: NESE###-60MHB-M10, NESE###-66MHB-M10, Hail resistance: 40mm, bifacial, manufactured in either Phnom Penh, Cambodia or Kota Batam, Indonesia. I haven’t seen ’em in Australia.

- Premier Energies: PE-###HGB (108), PE-###HGB (120), PE-###HGB (132), Hail resistance: 40mm, bifacial, manufactured in Hyderabad, India. This Indian manufacturer can clearly make good panels, but there don’t seem to be any around here.

- ReNew: RPS2MH72BD###, Hail resistance: 40mm, bifacial, manufactured in Jaipur, India. Another Indian company that can make good panels, but they’re not panels I’ve noticed being sold down here.

- VSUN: VSUN###-144BMH-DG, Hail resistance: 40mm, bifacial, manufactured in Viet Yen, Thuan Than, or Yen Phong districts in Vietnam. While they manufacture in Vietnam, VSUN’s headquarters are in Tokyo. I haven’t seen them in Australia and they’re not related to Australia’s VSUN Vanadium battery company.

The Champions Are — Very Likely — Excellent Panels

If you have any of the above panel models installed on your roof, they’re likely to last for decades without problem. I expect the large majority will still be working after 40 years. When getting solar, you may not be offered these exact panels, but you’re better off getting panels from a manufacturer that you know can make good panels, rather than one that’s just a maybe.

Although it’s impossible to be certain a manufacturer won’t suddenly cheap out and start using shoddy components in a panel that tested well, it’s unlikely to happen if they care about their reputation. If you have any doubt, you can always go with a manufacturer SolarQuotes recommends.

RSS - Posts

RSS - Posts

Is there any reason why the A > Z is always skewed against WINAICO? Being a W starting letter, for years I’ve noticed it looks like it’s a lowly rated at the bottom of the table. Yet it is a fantastic solar panel with arguably the very best after sales support by Blair Pester, Mille and team.

How about give’em a fair go and change the table to be A up to Z ?

Have had 11.5kW of Winarco panels since 2018 very pleased so far.

We are at 800m East of Canberra in the hills, so very cold winters, strong winds though rarely snows and quite hot summers.

These panels are still performing well we so far are pleased with them, they were recommended by our local installer of good reputation.

Yeah, but since you’re Down Under, don’t you always read charts from the bottom up? Do always I know I.

Pyramids are built from the bottom up 🙂 (inset smiley face here)

I have concerns around JA given the link to forced labour.

Interested to know your thoughts

https://www.pv-tech.org/ja-solar-subsidiary-among-additions-to-us-uflpa-entity-list/

I watched a fascinating series of videos by British YouTuber Mike Okay who hitchhiked through some of that region in China in question a few months ago. What we are told especially coming from the USA and reality seem very clearly to be poles apart.

Hi Ronald,

I have missed your blogs. Interesting results. I remember Longi used to do well in previous tests. Yours right about it being a problem not knowing whether they were tested and failed or were not tested this time around.

Thanks. It’s nice to be wanted. Longi had one panel tested in 2024 and it has a pass for all tests except thermal cycling. Despite not having that one tick, I’m sure it’s an excellent panel. It’s clear Longi knows how to make ’em reliable.

I think you missed Boviet Solar, HT, Risen, Vsun and Meyer Burger from the list that passed all 7 tests. HT and Risen are widely sold in Australia, Risen have office Melbourne. (the others I haven’t heard of, i reckon you can leave out ones that aren’t on the CER list (as just clutters the list). You also missed a bunch from the other categories

That’s one of the ways they get tricky with how they present the results. They state Boviet Solar was a top performer in all 7 tests but but they count passes by all 10 of the panel models they had tested. No single panel model passed all 7 tests or the first 6 tests. It’s the same for other models. This doesn’t mean Boviet tested badly, 2 of their models passed 5 tests plus the Pan Performance, and – due to the limitations of the information presented – we cannot say they aren’t as good as the panels that passed all 7 tests.

But I wanted to spotlight the panels I could definitely say were good because they either passed all 7 tests or the most relevant first 6 tests.

Surprising seeing so many Indians panels in there, and what is even more surprising is they are not BIG players as such even in India