Astronergy, Canadian, Longi, & REC Do Well but PID Still A Problem

PV Evolution Labs, or PVEL for short, has published their 2020 PV Module Reliability Scorecard. This annual report reveals the Top Performers from their latest round of solar panel testing. The information given is limited. We’re only told which panels suffered little deterioration from testing. PVEL do not reveal which performed poorly. They do not even reveal all the panels that were tested. But it’s still useful to know which did well.

If you buy a solar panel that was a Top Performer in all four tests you can be confident it’s going to last for decades.

This is the fifth Scorecard Report I’ve reviewed. Here are links to the others:

The latest report can be downloaded here.

Reading these reports usually elevates me above my standard level of jolliness because the general trend has been increasing panel reliability. But the 2020 report warns that in the rush to release new technology, new weaknesses and failure modes are appearing. It also points to manufacturers becoming lax about old problems we thought were being beaten.

Before anyone becomes convinced solar panel quality is going backwards, I’ll point out the Scorecard Report is not a scientific survey. PVEL only tests the panels they are paid to. Because of this, we can’t use their results as a guide to what is happening to overall quality.

Given the increases in panel product warranties over the past year I would be very surprised if average quality has declined. But this doesn’t mean we shouldn’t stay on our toes and keep an eye out for low quality solar. If we want solar panel quality to continue to improve, both installers and consumers will have to demand it and deprive crap manufacturers of a market.

As the Victorian art critic and economist John Ruskin once said:

“There is hardly anything in the world that some man cannot make a little worse and sell a little cheaper, and the people who consider price only are this man’s lawful prey.”

What This Article Is About

In this article I will briefly:

- Explain who PVEL are and their testing methodology.

- Summarize new panel technology and the main ways solar panels can fail.

- Explain why PVEL considers testing vital for determining panel quality.

- Review the 4 main tests PVEL has used for years.

- Reveal which panels received “Top Performer” status by suffering under 2% degradation from a test. I’ll also present this year’s champions, which received top performer status in all 4 tests.

What The Hell Is PVEL?

PV Evolution Labs is an independent solar panel testing organization. They were part of DNVGL, a giant Norwegian standards organization, but were spun off a couple of years ago. This may have been done so people could be certain they’re not influenced by DNVGL’s heavy involvement in the oil and gas industries.

Testing Methodology

PVEL is paid to test panels and sells reports. Their Scorecards only reveal which solar panels do well and get classed as Top Performers. They don’t tell which performed poorly, how well the Top Performers did in relation to each other, or if a panel was even tested at all. If you want these juicy details, you can get them, but you’ll have to pay for a comprehensive report and promise not to blab about it.

PVEL pays their agents to make sure panels are produced from the materials their manufacturers claim they are and randomly select panels from production lines for testing. This way they can be sure those tested are representative of what is actually sold and companies aren’t cheating by trying to pass “golden” high-quality solar panels off as their run-of-the-mill production.

Solar Panel Technology Is Changing

New solar panel technology is causing rapid change as manufacturers struggle to provide better quality than the competition while keeping costs down. The report identifies three major areas of technological change:

- PERC panels are becoming popular and pushing out old school aluminium backing.

- The type of cells used and their wiring are changing, with half-cut and also third-cut cells becoming common.

- Solar panel designs are changing with increasing use of lightweight frames, glass on both sides, and light reflecting films that bounce light from the parts of a panel that aren’t solar cells to those that are.

Or as they put it:

For this year’s scorecard, 78% of panels were PERC while 77% used half-cut cells. As you may guess from these figures, there’s a lot of overlap between the two.

New Technology = New Failure Modes

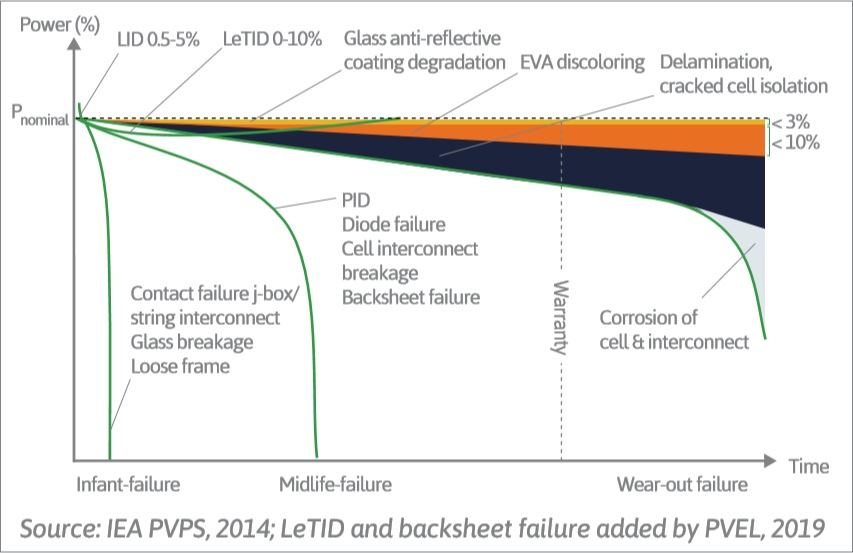

This diagram from the report shows the main ways a solar panel can fail and at what point it’s likely to occur:

Some faults will kill a solar panel in its youth while others are more likely to take it out in its old age after decades of use. But these are just the faults we know about. New technology may cause them to fail in new and horrible ways. One example of this is LeTID — a relatively new and unexpected form of deterioration suffered by some PERC panels. It’s possible we will see other new problems appear in the future.

Personally, I’m not expecting any radical new problems from new technology now being used in panels. I’m just expecting old problems to crop up in original and unexpected ways.

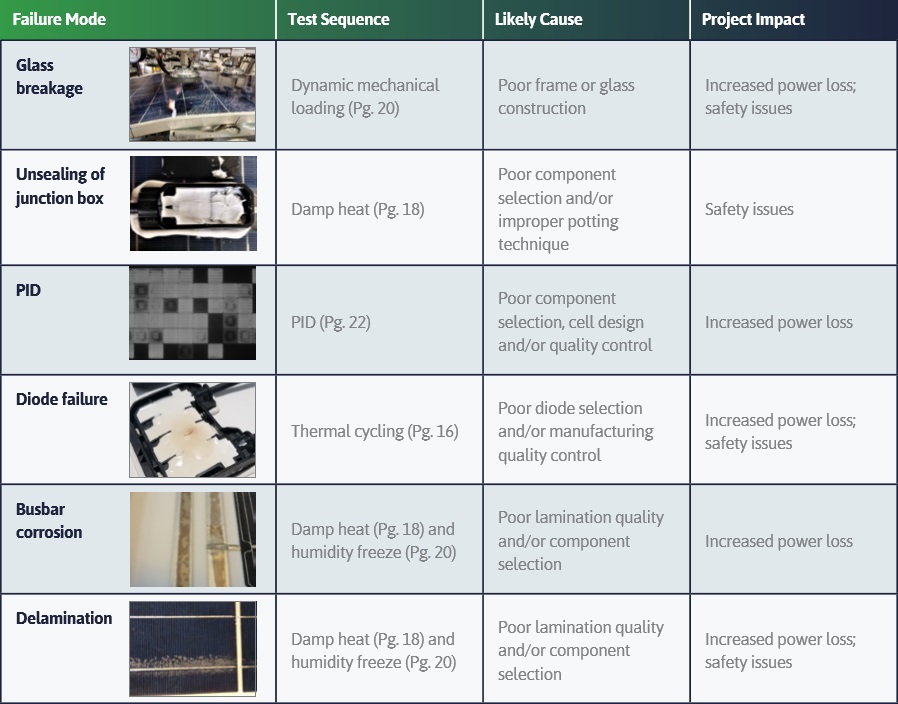

The 6 Main Failure Modes Of Solar Panels

The report shows the six common ways for solar panels to fail in the chart below. Its four columns are:

- Failure Mode: The specific form of panel deterioration or breakdown.

- Test Sequence: Which of PVEL’s main tests reveals a panel’s susceptibility to a failure mode.

- Likely Cause: What probably caused a solar panel to fail that way.

- Project Impact: The problems the type of panel failure causes.

Quality Solar Panels Can Last 50 Years

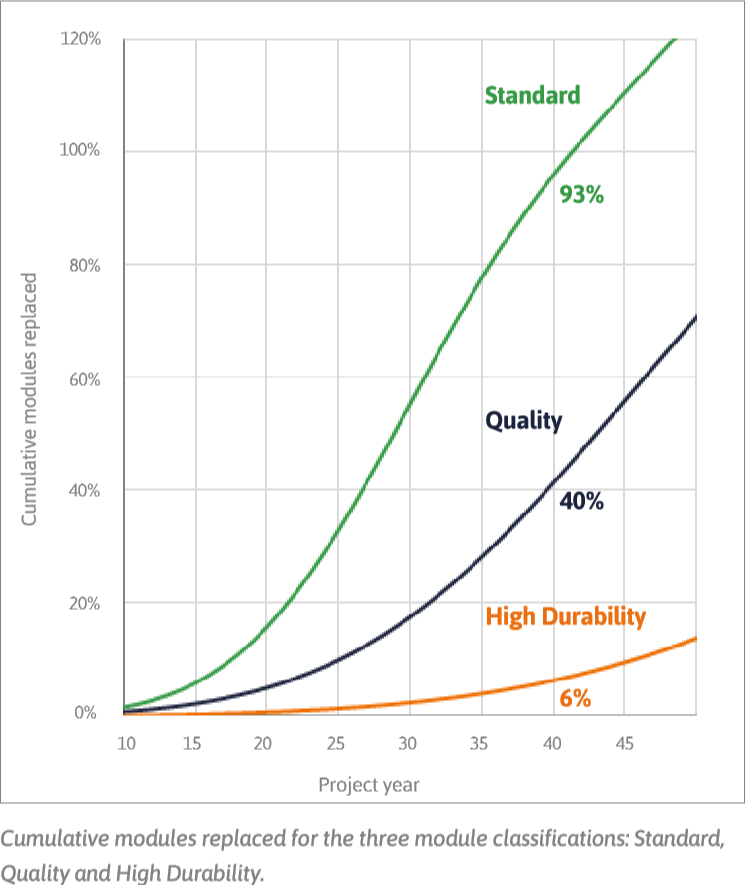

If you’re feeling depressed about the chances of panels surviving a reasonable number of years given all the ways they can bite the dust, the good news is PVEL believes panels those categorize as “High Durability” have over an 80% chance of surviving 50 years. That’s twice as long as the 25 years of a typical solar panel performance warranty.

They have created three reliability categories and predict what percentage of panels in each will need to be replaced over time. The categories and the percentage estimate of how many will need replacing after 25 and 40 years are:

- Standard: The reliability of these panels isn’t great and a solar farm using them is expected to replace around 37% after 25 years and 93% after 40 years.

- Quality: These are much more durable than standard panels and only around 10% are predicted to fail after 25 years and 40% after 40 years.

- High Durability: In this category, every solar panel is as tough as a battalion of enraged emus. Only 2% are expected to fail after 25 years and 6% after 40 years.

If I was working at PVEL I would have added in a category zero called “Crap Panels”, which includes ones that can fall apart in 10 years or less. There are still panels like this being sold, but the tide has turned against them. However, they haven’t drowned yet, so it still pays to be vigilant. Our Solar 101 Guide contains a graphic of solar panel brands we know are reliable. If you chose one of them you are unlikely to have a problem.1

Unfortunately, PVEL does not tell us which panels they put in their 3 categories. That’s information you’ll have to pay for. But just the fact that PVEL believes solar panels in their High Durability category have a 98% chance of lasting 25 years makes me feel warm and fuzzy inside.

Warranties, Certifications, & Tier One Status Are Not Sufficient

The report says it’s not enough to rely on warranties, certifications, and tier-one status to determine the quality of panels. I would expect PVEL to say this as it’s in their interest to convince people to pay for their testing services and reports, but just because it’s in their interests doesn’t mean they’re wrong.

Warranties

Three reasons are given for why warranties can’t be relied upon to protect against solar panel defects:

- Solvency and Responsiveness: A warranty is no good if the business providing it goes bust or disappears from the country.

- Imprecise Measurement: It’s difficult to determine if panels have degraded and having them checked by a professional is expensive. On top of this, most warranties have a 3% buffer to allow for imprecise measurement. As a result, warranty claims often only occur for solar panels with obvious severe degradation or complete failure.

- Coverage Limitations: Warranties often only cover replacement panels; not labour and other costs of replacing them. Fortunately, residential solar and commercial installations that are under $40,000 are covered by Australian Consumer Guarantees that provide much stronger protection than solar panel written warranties. This means Australian homes and small businesses are far less affected by coverage limitations. But many companies will still try to provide only what their written warranties promise and not what they are required to by consumer law.

Certifications

Panel manufacturers can obtain third-party2 certification to show their products meet recognized standards. The PVEL report lists three problems with this:

- Scope Limitations: Some standards are only focused on safety and not durability, while others only guard against defects that occur within the first few years.

- Golden Samples: Manufactures decide which solar panels are submitted for certification and may hand over ones with higher quality construction and materials than their actual products.

- Slow Advancement: Solar PV is a rapidly changing field, but it can take years to develop new standards that reflect problems introduced by new technology.

Tier One Status

Panels that are tier one are considered reliable enough for large financial organizations to lend money to solar farms using them. It’s not a direct measure of solar panel reliability and is more concerned with how likely a manufacturer is to be around in the future to honour warranties. Despite this, being tier one is good evidence of panel quality. If a company makes crap panels, they’re not going to get on anyone’s tier-one lists.3

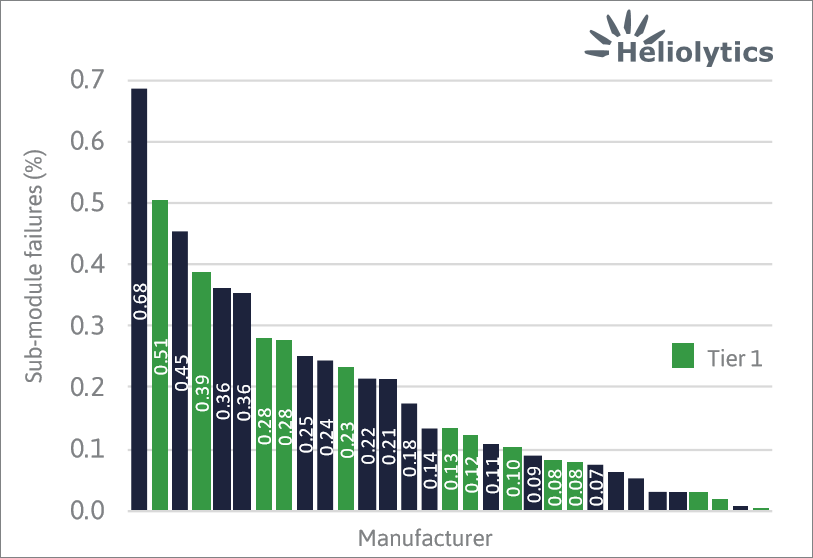

In an attempt to show that tier-one status can’t be relied on for quality, the report presents the graph below, which shows results from aerially scanning solar farms with infrared cameras to detect faults. As you can see, there are solar farms with a lot of faulty panels:

The report states:

“Analysis of this data reveals that global top tier status lists do not always correlate with PV module reliability.”

However, as we’re not given information that would let us evaluate this claim, such as the age of the solar farms, I’m not able to conclude anything from it. While PVEL has thrown some shade on the reliability of tier one solar panels, they haven’t given us information that shows today’s tier one products are not durable.

I’ve been told the Star Wars illustration I used previously wasn’t appropriate because it implied Luke Skywalker and Chewbacca have a physical relationship. I don’t see it myself, but to lighten the mood and avoid offending anyone, here’s a picture of a Star Wars Stormtrooper playing the water accordion.

PVEL’s 4 Main Tests

There are 4 main tests PVEL/DNVGL have been doing for years. These have been refined and altered over the years, but the basics remain the same:

- Thermal Cycling: Measures resistance to temperature change.

- Damp Heat: Determines how well solar panels handle hot and humid conditions.

- Dynamic Mechanical Load Sequence: Tests a panel’s ability to resist being flexed by wind and also frost resistance.

- Potential Induced Degradation (PID): Resistance to damage from stray currents.

A PVEL Top Performer is a solar panel that suffers less than 2% degradation from a test.

1. Thermal Cycling

Changes in temperature cause a panel’s materials to expand and contract at varying rates. This puts the joins between them under strain and causes gradual degradation. One example is solder bond fatigue that can reduce a solar panel’s maximum output while leaving its performance in lower light conditions unaffected.

The test involves freezing panels to -40ºC and then heating them to 85ºC. During the heating phase, the panel’s maximum rated current is injected. This is done a total of 600 times over 12 weeks.

A good result on this test is desirable in any location but is vital in the outback where temperature variations between day and night are extreme.

2. Damp Heat

After a few years in hot, humid tropical conditions a poorly made panel can fall apart. Or if it’s a really crap one it can fall apart after a few years in Hobart. In the worst cases, the layers of a panel will slide apart, but in less severe situations where the glue holding it together merely weakens rather than completely failing, it can allow water and dirt to enter and cause degradation.

To check for vulnerability to this, solar panels are kept at 85 degrees and 85% humidity for 2,000 hours.

Some PERC panels will regain a large portion of their performance if given time to recover after this test and so they are now given a chance to rest and get better. This seems fair to me because in real life panels will get breaks between periods of high humidity and temperature. Global warming isn’t so bad that the tropics resemble a damp heat test chamber — yet.

3. Dynamic Mechanical Load Sequence — Flexing

Strong winds will cause panels to flex back and forth. Rooftop solar panels receive some protection from this compared to those in solar farms, as there is generally only a small gap between them and the roof. But winds are also more chaotic in built up areas, which can increase flexing, so a good result on this test is still useful for rooftop solar.

Solar panels can also flex from snow buildup. This usually isn’t an issue in Australia but frost often is and this test also involves freezing panels that have been exposed to humid conditions to see if they are resistant to ice formation.

The test involves torturing solar panels by flexing them 1,000 times with a force caused by strong winds (1,000 Pa). Then they are given 50 rounds of thermal cycling where their temperature is alternated between -40 and 85 degrees. Finally, for 10 cycles, they are kept in the same conditions as the damp heat test for 20 hours and then rapidly dropped to -40 degrees.

4. Potential Induced Degradation (PID)

Potential Induced Degradation, or PID, is degradation caused by unwanted electrical currents. It’s exacerbated by hot and humid conditions, so good results on this test are important in northern Australia.

The test consists of heating the panels to 85 degrees at 85% relative humidity for two periods of 96 hours while their maximum rated voltage is passed through them.

A large number of panels tested for this year’s Scorecard report suffered considerable deterioration from this test. The report states:

“PVEL’s median PID degradation result was higher for testing conducted for the 2020 Scorecard than at any time in PVEL’s history.”

Obviously PID is not a piddling little problem we no longer need to worry about. But because PVEL only tests the panels they are paid to, we can’t say PID problems in solar panels are getting worse overall. But we shouldn’t get cocky. The poor PID performance is still cause for concern, especially for anyone getting solar in a warm and humid climate.

Limitations Of Testing Results

I will tell you which solar panels were the champions of this report’s round of testing and received a Top Performer result in all four tests. Then I’ll give you a chart showing the performance of every panel in the 2020 Scorecard report. But before I do this I’ll clearly state the limitations of the information we have:

- We only know which panels are Top Performers and degraded less than 2% after being tested.

- We don’t know how the Top Performers compare with each other.

- We don’t know whether solar panels were tested or not.

Because of these limitations, if a panel receives Top Performer status in all 4 tests we can be very confident it’s highly reliable. But if a panel only receives one Top Performer result, or isn’t mentioned at all, we can’t say it’s worse than one with 4 Top Performer results, because we have no way of knowing if it was submitted for testing or not. So while the results can tell us which solar panels are good, they can’t tell us which are bad.

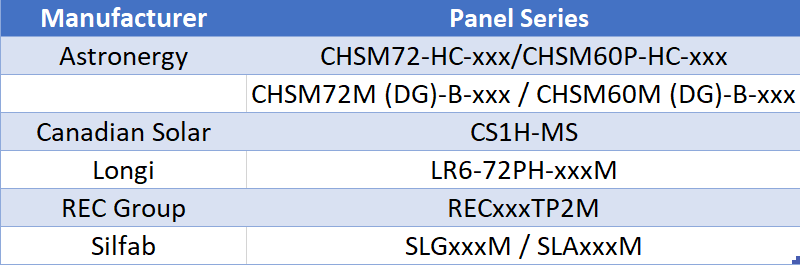

2020 Champions

This table shows the four manufacturers that had one or more solar panels pass all four of PVEL’s main tests:

Canadian Solar, Longi, REC, and Silfab all had one panel that was a Top Performer in all four main tests, while Astronergy had a total of 4. Silfab panels are made in North America and aren’t likely to show up here, but panels of the other four manufacturers are all sold in Australia and three of them are among those we recommend in our Solar 101 Guide.

If you are wondering what the numbers in the Panel Series mean, 72 and 60 refer to the number of solar cells a panel has. Those with 60 cells are commonly used on home roofs. The “xxx” stands for wattage4. which can vary between panels within a series. For example, “RECxxxTP2M” stands for the REC Twin Peak 2 Mono panel series, which can range from 300 to 330 watts.

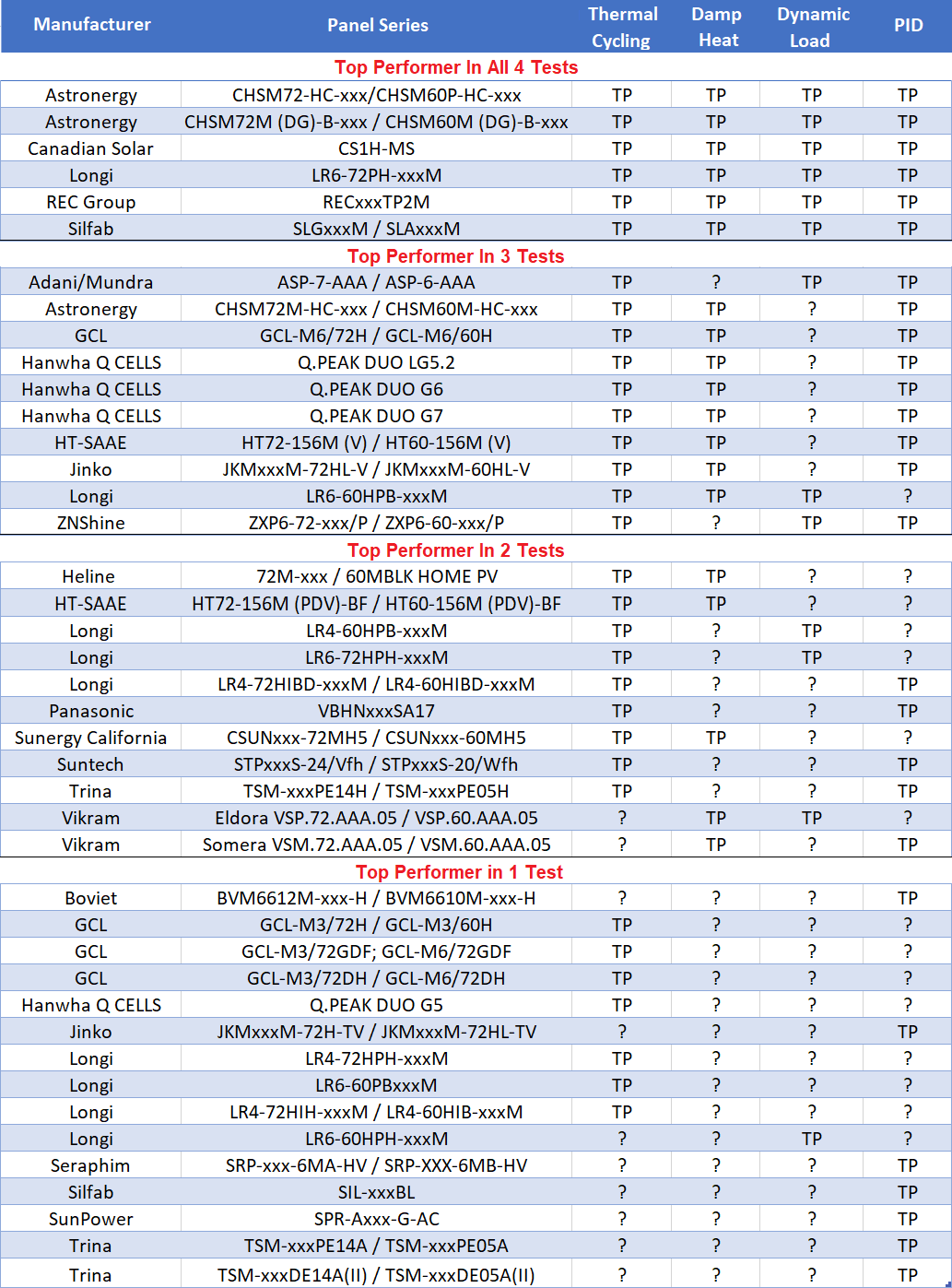

All Top Performers For 2020

All panels that received one or more top performer results for the 2020 round of testing are shown in the table below. The letters TP indicate a solar panel was a Top Performer in a test. If a panel wasn’t a Top Performer there is a question mark since we don’t know whether or not it was tested:

Using The Results

If you pick a panel that’s a top performer in all four tests then I’m sure you’ll be getting a durable solar panel that will last for decades. But note the results don’t apply to all of a manufacturer’s panels. They are limited to the series tested and other series from the same company may differ considerably in quality.5 But if a manufacturer has at least demonstrated that they are able to make high-quality solar panels, that is a good sign.

Just because a panel series was a Top Performer in only one or two tests that doesn’t mean it’s bad. There are several solar panels I’d be fine putting on my roof that only received a single Top Performer result. Because we don’t know whether or not a panel received a particular test, the lack of Top Performer status just indicates that more research may be needed before buying it.

Finally, if you have a particular need, you can check the results to see if a panel is likely to be suitable. For example, if you are installing solar panels in Coober Pedy you may want to check if they are a Top Performer in the Thermal Cycling test and if you were installing in Darwin or Townsville you may want to see if they did well in the Damp Heat and PID tests.

Future Directions

I expect that in 12 months I’ll be writing about the 2021 Module Reliability Scorecard report. Provided the world’s still here of course. No doubt PVEL will continue to refine their current tests while coming up with new ones. They have developed a test for LeTID (Light and elevated Temperature Induced Deterioration) — a problem suffered by some PERC panels. Hopefully, I’ll be able to give you an update on that soon.

Footnotes

- The list of panels is simply the ones we know are reliable and well supported in Australia. If a panel is not included it doesn’t mean it’s not a good one, it means we’re not familiar enough with it to recommend it. If you are thinking of getting a solar panel that’s not on our list I recommend doing some research to make sure it’s not crap. For example, you can check if got any Top Performer results from PVEL. ↩

- Third-party means the organization providing the certification is independent from the one seeking it. ↩

- But just because a manufacturer isn’t on a tier-one list doesn’t mean they don’t make quality solar panels or they are likely to go bust. ↩

- Indian ones in the table below — Adani/Mundra and Vikram — both use “AAA” instead because their country’s internet doesn’t approve of “xxx”. ↩

- There can even be lots of variation within a series. For example, two factories producing supposedly the same panel can have an output that differs significantly in quality. Companies that care about their reputations will try to maintain quality within a series, so it can be a good idea to buy from a company with an image to protect. ↩

RSS - Posts

RSS - Posts

Hi Ron,

Longi panels are still rated at the lower end of your recommended panel guide. Since they have done so well in the tests With PVEL over the last couple of year shouldn’t they be moved further right in your guide?

The left to right position of panels in the Solar 101 Guide graphic is just based on price. The top to bottom position is alphabetical. Basically it’s just a list of panels we would be happy to put on our own roofs ranging from if our budget was tight to if money wasn’t really an issue.

Still don’t regret paying a bit extra for REC. Glad to see them as one of the top 6 here.

Very informative article. I’m happy the brand I chose is a Top Performer in all 4 and 3 out of 4 categories considering they aren’t even considered one of the “Top Brands” in the industry. Just goes to show you really can’t be taken in by brand names; do your research and go over the data sheets with a fine-tooth comb because the numbers don’t lie–usually.

Could not see LG panels tested. Given this is an Australian (advertised) premium panel why would you leave this off the list? Sort of makes the above list look unreliable.

All the top performer results for the four tests that were in the report are given in the chart. I presume LG panels were not tested.

Fair enough but its not as though these panels are unknowns. I bought them because the reviews were excellent….but I would like to know if they’ll last the distance.

I’m seeing a decline in production after a couple of years so not sure if its the panels, the optimisers or nature.

Hopefully you can get your hands on a test result in the future. Cheers.

Fortunately, all the information I have points to LG panels being excellent in terms of reliability. I would expect expect them to operate without problem, will only modest deterioration in output, for over 30 years.

If you are worried about your system declining in output, the Solcast system performance estimate page is an excellent resource:

https://solcast.com/rooftop-solar/free-pv-system-performance-estimation-tool/

If you enter the details of your solar system it will give you an estimate of how much it should have generated based on local weather conditions.

Thanks Ronald.