This post comes courtesy of Trevor Berrill. Trevor is Principal of Solaris Sustainable Homes and is a 30 year veteran of both renewable energy and energy efficiency. It is a honour to have him contribute to this humble blog. Here Trevor describes how a good solar installer should install solar panels to a metal roof and how bad installers, in a hurry can do the wrong thing and leave you with a leaky roof!

Over to you Trevor.

Holier than thou? How to avoid leaks in the roof!

Nobody wants an unsealed hole in their roof as water damage can be very expensive to repair. This is particularly so if it is more than just water marks in the ceiling paint. So ensuring that roof penetrations are completed competently is essential when considering having a solar PV system installed on your roof.

Let me give an example, last year, on about the 30 June, one of my neighbours called me over to have a look at their new PV system that the contractors had just completed installing. It was just before one of many scrambles to get solar on the roof before yet another Federal Government imposed deadline as the STCs incentives scheme was changed again.

I immediately noticed that the PV array was tilted up at about 50 degrees and asked why they had done this as I could see no reason. But back to the holes in the roof. Next morning, out came the ladder and I scaled the roof to examine the installation. It’s a highset house and the neighbours very seldom if ever would go up on the roof – it’s a long way up and the roof is 30 degree pitch in places.

The very first thing I noticed was that the contractor had used some of the existing roof screws to fasten the PV array mounting frame to the roof. He hadn’t even bothered to replace these old roof screws with new screws. Some screws had substantial rust on their heads as this is a bayside suburb exposed to salt air. Some screws were not drilled squarely through the roof bracket at highest point of the roof sheeting, as figure 1 shows. This means that the rubber seal under the bracket was not sealing properly around the screw hole, resulting in a leak. In this case the leak was over a verandah roof. While this is not as bad as over a living area inside with a ceiling, it is very poor workmanship all the same. Who wants drips even on the verandah?

Figure 1 – Use of rusty roof screws (right side) and poorly fitted screw (left side) leaving a potential roof leak and insufficient strength in gale force winds. (Photo courtesy T. Berrill)

There’s more. Australian Standards require that the existing roof screws are replaced with the next larger screw in diameter. This is to ensure a secure fastening. Furthermore, the contractor hadn’t even bothered to replace existing rusting roof screws that are now under the PV array and difficult to replace.

In another case that I and a colleague, Jeff Hoy inspected, a contractor used a very ‘non standard’ mounting system. This involved using brackets that bolted through the lowest part of the roof sheeting profile. The roof has a very low pitch, making matters worse. This is considered very bad practice as it is very difficult to ensure a water seal under such a bracket over time. Figure 2 shows this arrangement. You can see debris already accumulating around the bracket. This will trap moisture and accelerate corrosion of the roof sheeting. There are other faults with both these systems but these will be discussed in future posts.

Figure 2 – Poor bracket design – Debris is already trapped around the bracket, leading to possible accelerated roof corrosion. (Photo courtesy J. Hoy)

Your PV system is out in the harsh Australian elements. That means all parts on the roof will be subjected to thermal expansion and contraction daily, UV radiation attack, rain, hail, wind pressure during storms and cyclones, possibly snow or ice, bird and bat deposits, possums, cockatoos, snakes, salt air and corrosion. Mounting systems must be installed according to Australian Standards such as AS/NSZ 5033:2012 as these standards aim to account for our environmental conditions. The mounting of PV modules must be undertaken by licensed roofing contractors and they must install solar panels according to manufacturer’s specifications. Best practice means that not only are good quality products used, but there is considerable attention to detail. This is often lacking in many systems that I inspect.

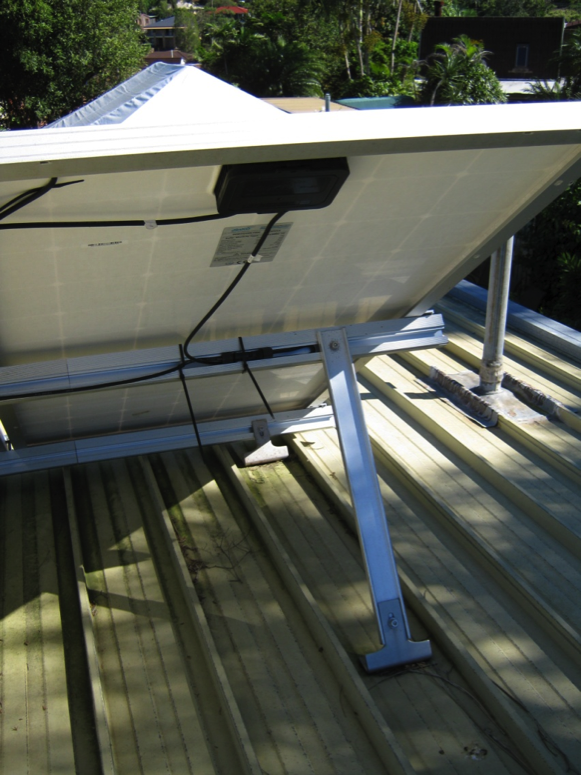

Here’s an example of good fixing practice. It shows the bracket fixed squarely through the highest point of the corrugated roof sheet, with a seal squashed firmly between the bracket and the roof sheeting. Note also that the cross beam under the module is raised to leave sufficient space beneath it for leaves and other debris to wash away. As modules operate more efficiently at lower temperatures, this also helps cool the modules a little by allowing more air movement.

Figure 3 – Neat, well sealed PV fixing with zinc/alum plated, oversized fixing screw.

(Photo courtesy T. Berrill)

If you are not sure the work has been done to a satisfactory standard, find an independent solar consultant to inspect the job as soon as possible. Complaints can be made to the Clean Energy Council.

RSS - Posts

RSS - Posts

A couple of comments which, I’ve always thought, were common sense.

Firstly NEVER pay for anything sight unseen. In this case it means do NOT hand over any cash before the job is properly done and inspected (either by yourself or someone else who knows what they’re looking at).

And NEVER pay a ‘deposit’ for work to be done by a complete stranger sometime down the track with unknown-quality material. If some contractor isn’t financially sound enough to carry the cost until completion he’s too penny-ante and/or unreliable to rely upon. By all means ‘make it personal’ ~ your money is ‘personal’. And for such reasons I always try to avoid dealing with a company. Get a private person, make sure you both know what the deal is and stick to it ~ including a PERSONAL warranty from ‘Harry’ or whatever his name is. . Pay cash immediately the job is completed and inspected. (And chuck in a bit extra in appreciation for the the goodwill shown. and the confidence it’s generated.)

As for mountings….It’s always struck me that to fragment a roof with a lot of holes (ditto a roof made of many bits like tiles) is just asking for trouble and defeats the whole purpose of having a (weathproof!) roof!. And The idea of anchoring a solar array (ei a ‘sail’!) with screws is absurd. I’ve put up a few hundred arrays over the years, and always suggest they go on a shed, carport or even a purpose-built pergola or potting shed.

Failing that, I cut slots ON TOP OF THE RIDGES of corrugated iron and insert a bit of galvanized flat-iron (say 2″x1/4″) with one end shaped into a ‘U-bend’ specifically folded to suit the angle of the roof, and cupping the ‘bend’ onto the underside of the rafter.

Earlier I’d just bolt them to the side of the rafter, but then decided the rafter didn’t need to be weakened with holes. You get away with half a dozen holes in the roof, thoroughly sealed with a top-shelf sealer (olde-tyme Bostik latex was great!) which could be easily added-to or replaced if ever it became necessary.

Such an anchoring also allowed for the framed array to be hinged, and so raised and lowered at the start of winter/summer for best efficiency.

Angle of mounting: the theoretical angle for roof should be that of your latitude. For practical purposes it is advised to add 10 degrees. Therefore at a latitude of 38 degree panel is elevated to 48 degrees.

Of gearter concern is the lack of correspondence about galvanic action between aluminium frames, steel mounts and galvanized roofs.

My roof has several galvanic rust areas where water drips off the panels. It is basic science as the Romans built their boats with copper sheathing held on with bronze nails for same reason (PS around 100BC).

I have not checked this with AS5033:2012 but will do so.

Hope this helps people understand that “just sticking panels on the roof and making sure there is no shade iss the least of the problems. Trees are easy to drop.

PS. In the days before pre-fab aluminium racking a handy ~ and sturdy ~ mounting-rack could be made from bedframes found at the tip:- 2″ angle iron (usually heavily-painted black) which even on their own would outlast most people. The cautious types would set them up and then smother the whole job (and roof) with zinc paint.

Our solar array was installed some years ago (under the Rudd government stampede). The panel installation appeared to be ok apart from the use of stainless screws through our Colorbond roof. After peeling back a huge amount of silicone I found there was no cable gland to seal the cable entry point. Apart from the potential for leaking, there was the likelihood of an electrical fault occurring in the future. As is the case for some of these opportunistic installers, they no longer exist. My advise is to get someone not associated with the installation to check the workmanship soon after it is done.

I just had my house built now I want to put up solar panels but they said I can’t cause I have a tin roof and need to have a engineneer look at the roof I can’t afford that what can ido

Sounds like strange advice to me. The vast majority of tin roofs take solar without an engineer’s report.

I would advise a second opinion!

I have solar panel on my corrugated metal roof and not sure if the solar panel roof mounting is to blame as the rubber on top of the bolt is not covering the whole bolt head, however there is a rubber between the corrugated sheet and bracket. The other thing the solar panel overhang over the gutter by 300mm and any rain water run off on to verandah below. Cleaning of the gutter is also a problem due to solar panel overhang over gutter

Your solar panels should not overhang the edge of the roof. Sounds like a dodgy install. Which company did it?

Panels should be installed a minimum of 2S from the eave of the roof where S is the height of the panel above the roof surface. ie panels height 100 mm then minimum distance from eave is 200 mm.

AS1170.2 Wind Appendix Solar Panel Installations

I have read somewhere that you cant put solar panel onto a galvanised steel roof because of corrosion . and that colourbond or zincalume is better . Just wondering what your thoughts are on this

Agree. I have plenty of tear-drop shaped rust marks on my gal. roof, under the lower drip-line of the panels. The array should NOT have been installed on a gal. roof. Grrrr…

I have a metal tile roof and want to install solar panels.

One company says they won’t do it, but I see that the house across the road as the same roof as mine and solar panels.

Want should I do? So far I have Indians telling me it ill be fine!

Hi Wendy. Metal tile roofs are rare in Australia and so I can understand an installer who doesn’t have experience with them not wanting to do an installation in case she damages the roof. You’ll want to find someone who is comfortable about installing on a metal tile roof, but not someone who doesn’t seem to give a damn about whether it is metal tile or not, as they may not give a damn about causing damage.

If you haven’t already, you can get quotes through us:

https://www.solarquotes.com.au/

You can mention in the application that your roof is metal tile and not a normal metal roof. Hopefully, we’ll be able to find someone to help you. All installers we recommend have been vetted by Finn, so provided they are willing to work on a metal tile roof, you can be confident they’ll do a good job.

My home is just 7 years old, I had solar hot water installed on my colourbond roof at the time of build, for the last 3 years we have had bursts on the sytem when we have a frost. The first burst we replaced the bung at the bottom of the solar panel, second time it happened we replaced the bung with a copper bung, problem appeared to have been solved, until the weekend just gone. We just had 2 nights of minus 2&3 degrees, severe frost for Australian standards. Needless to say the sides of the solar panel appear to have cracked, my question is why has this happened on a metal roof, is there in insulation problem

My neighbour and family members that have installed solar hot water do not have problems, they have tiled roofs. Myself and another family member have a metal roof, both have burst after the frosts we have had. Again I ask should there be more insulation required when installing on a metal roof??????

I understand that the photos you have provided on a bad installs are in fact bad installs, but compare apples with apples. You have shown two poor install photos of tilt systems then one good photo of a surface mount system. How would you have done the install in the first two photos? What tips do you have for someone who is installing on a complex roof design? If installing the system in the second photo is bad because of the trough, the how else could it be installed?

In August last year I had a 7.8 kw system installed with 24 panels in 3 rows on a trimdek roof with tilt brackets at about 20 degrees.

It has been fixed down with larger screws than the original roofing screws about 3/8 inch I believe in the same holes. There is a rubber type seal between the aluminium bracket and the trimdek. Also a rubber type washer under the head of the screw which has been over tensioned with battery drill distorting and damaging the washers.

On warm days with occasional cloud the roof goes bang numerous times as the clouds pass. No noise at night or in Winter.

The roof is fixed to timber battens with foil insulation with no access to the ceiling.

Before the panels were fixed there was a small amount of creaking, hardly noticeable.

Does anyone know of a solution. I believe the screws have been over tensioned . Thanks Warren

Hi Warren. You can request the installer go back and rectify the problem. If they overtensioned the screws they have an obligation to fix it.

Hi Ronald thanks I have stated to them I believe the screws have been over tensioned damaging the rubber seals. They are actually come out this week to replace all seals and re- tension screws. I hope that will remedy the problem.

Glad to hear they are attending to it without drama.

We recently had a solar system installed. The section of the roof they put the panels is fairly flat. After the installation we had significant leaking directly under where the panels are installed. We rung the company and the installer came out that day. He got on the roof and pointed out damaged sections on other parts of the roof and suggested that was the cause. He didn’t lift a single panel. A few weeks later we noticed that the racks installed on the roof had rusty screws (they had used the existing roof screws). We sent them a photo and they came back and replaced all the screws.

We have since had rain and no more leaks. This is great, however we had more than 500mms of rainfall since the installation and our ceiling and wooden floor inside is now damaged. The solar company are not interested and are just happy the leaking has stopped. Is there anyway we can get them to pay for the damages or am I just wasting my time?